What is Global Industrial Air Dryers Market?

The Global Industrial Air Dryers Market is a significant segment within the broader industrial equipment sector. Industrial air dryers are essential devices used to remove moisture from compressed air, ensuring that the air used in various industrial processes is dry and free from contaminants. This is crucial because moisture in compressed air can lead to equipment damage, product spoilage, and inefficiencies in industrial operations. The market for these air dryers is driven by the increasing demand for high-quality compressed air in various industries such as manufacturing, food and beverage, pharmaceuticals, and chemicals. The global market encompasses a wide range of air dryers, including refrigerant dryers, desiccant dryers, and membrane dryers, each catering to specific industrial needs and applications. As industries continue to expand and modernize, the demand for reliable and efficient air drying solutions is expected to grow, making the Global Industrial Air Dryers Market a vital component of industrial infrastructure worldwide.

Refrigerant Dryers, Desiccant Dryers, Membrane Dryers in the Global Industrial Air Dryers Market:

Refrigerant dryers, desiccant dryers, and membrane dryers are the three primary types of industrial air dryers that play a crucial role in the Global Industrial Air Dryers Market. Refrigerant dryers work by cooling the compressed air to a temperature where the moisture condenses into water, which is then removed from the system. These dryers are widely used due to their efficiency and cost-effectiveness, making them suitable for general industrial applications where the dew point requirements are not extremely low. Desiccant dryers, on the other hand, use a desiccant material to absorb moisture from the compressed air. These dryers are capable of achieving very low dew points, making them ideal for applications that require extremely dry air, such as in the pharmaceutical and electronics industries. Desiccant dryers can be further classified into heatless, heated, and blower purge types, each with its own set of advantages and operational mechanisms. Membrane dryers utilize a selective permeable membrane to separate moisture from the compressed air. These dryers are known for their simplicity, low maintenance, and ability to operate without electricity, making them suitable for remote or hazardous locations. Each type of dryer has its own unique features and benefits, catering to different industrial needs and environmental conditions. The choice of dryer depends on factors such as the required dew point, energy efficiency, maintenance requirements, and initial investment costs. As industries continue to evolve and demand higher quality compressed air, the market for these diverse types of air dryers is expected to grow, driven by technological advancements and the need for more efficient and reliable air drying solutions.

Food & Beverage, Medical, Chemical Industry, Others in the Global Industrial Air Dryers Market:

The usage of Global Industrial Air Dryers Market spans across various industries, including food and beverage, medical, chemical, and others, each with its specific requirements and applications. In the food and beverage industry, industrial air dryers are essential for ensuring that the compressed air used in production processes is free from moisture and contaminants. This is crucial for maintaining product quality and safety, as moisture can lead to microbial growth and spoilage. Air dryers are used in processes such as packaging, bottling, and conveying, where dry and clean air is a necessity. In the medical industry, the need for sterile and dry compressed air is paramount. Industrial air dryers are used in applications such as medical device manufacturing, pharmaceutical production, and laboratory operations. The presence of moisture in compressed air can compromise the sterility and effectiveness of medical products, making air dryers an essential component in maintaining high standards of hygiene and quality. The chemical industry also relies heavily on industrial air dryers to ensure that the compressed air used in various processes is dry and free from contaminants. Moisture in compressed air can lead to chemical reactions, corrosion, and product degradation, affecting the overall efficiency and safety of chemical production. Air dryers are used in processes such as pneumatic conveying, mixing, and packaging, where dry air is critical for maintaining product integrity and process efficiency. Other industries, such as electronics, automotive, and textiles, also benefit from the use of industrial air dryers. In the electronics industry, dry compressed air is essential for preventing moisture-related damage to sensitive components and ensuring the reliability of electronic products. In the automotive industry, air dryers are used in painting, assembly, and testing processes, where dry air is crucial for achieving high-quality finishes and preventing corrosion. In the textile industry, air dryers are used in processes such as spinning, weaving, and dyeing, where moisture control is essential for maintaining product quality and consistency. Overall, the usage of industrial air dryers in these diverse industries highlights their importance in ensuring the efficiency, safety, and quality of industrial processes and products.

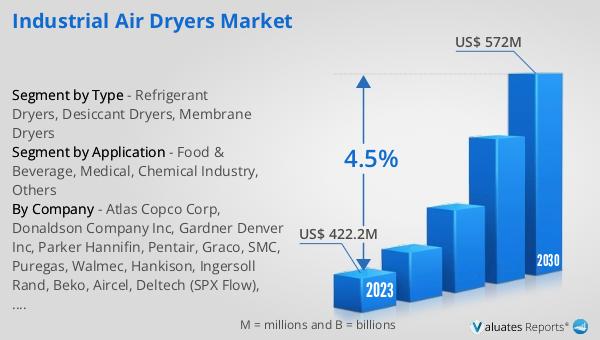

Global Industrial Air Dryers Market Outlook:

The global Industrial Air Dryers market was valued at US$ 422.2 million in 2023 and is anticipated to reach US$ 572 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This growth reflects the increasing demand for reliable and efficient air drying solutions across various industries. As industries continue to expand and modernize, the need for high-quality compressed air becomes more critical, driving the demand for advanced air dryers. The market's growth is also supported by technological advancements and innovations in air drying technologies, which offer improved performance, energy efficiency, and cost-effectiveness. Additionally, the growing awareness of the importance of maintaining clean and dry compressed air in industrial processes is contributing to the market's expansion. The increasing adoption of industrial air dryers in emerging economies, where industrialization is on the rise, further supports the market's growth prospects. Overall, the global Industrial Air Dryers market is poised for steady growth, driven by the continuous demand for efficient and reliable air drying solutions in various industrial applications.

| Report Metric | Details |

| Report Name | Industrial Air Dryers Market |

| Accounted market size in 2023 | US$ 422.2 million |

| Forecasted market size in 2030 | US$ 572 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atlas Copco Corp, Donaldson Company Inc, Gardner Denver Inc, Parker Hannifin, Pentair, Graco, SMC, Puregas, Walmec, Hankison, Ingersoll Rand, Beko, Aircel, Deltech (SPX Flow), Quincy Compressors, Sullair, Hitachi, CKD, MTA, Kaeser Compressors, ZEKS, Anest Iwata |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |