What is Global Hydro-processing Catalysts Market?

The Global Hydro-processing Catalysts Market is a specialized segment within the broader chemical industry, focusing on catalysts used in refining processes to remove impurities from petroleum products. These catalysts play a crucial role in enhancing the quality and performance of fuels and other petroleum derivatives. Hydro-processing catalysts are essential in various refining processes, including hydrotreating and hydrocracking, which help in the removal of sulfur, nitrogen, and other contaminants from crude oil. This market is driven by the increasing demand for cleaner fuels and stringent environmental regulations aimed at reducing emissions. The catalysts are composed of metals like nickel, cobalt, molybdenum, and tungsten, which are supported on materials like alumina or silica. The market is characterized by continuous innovation and development to improve catalyst efficiency and lifespan. The global hydro-processing catalysts market is expected to grow steadily, driven by advancements in refining technologies and the rising need for high-quality fuels.

Hydrotreating, Hydrocracking in the Global Hydro-processing Catalysts Market:

Hydrotreating and hydrocracking are two fundamental processes in the Global Hydro-processing Catalysts Market. Hydrotreating is primarily used to remove sulfur, nitrogen, and other impurities from petroleum fractions. This process involves the use of catalysts to facilitate the reaction between hydrogen and the contaminants, converting them into hydrogen sulfide, ammonia, and other harmless compounds. The primary goal of hydrotreating is to produce cleaner fuels that meet stringent environmental regulations. Hydrocracking, on the other hand, is a more complex process that breaks down larger, heavier hydrocarbon molecules into lighter, more valuable products like gasoline, diesel, and jet fuel. This process also uses catalysts to facilitate the reaction, but it operates at higher temperatures and pressures compared to hydrotreating. Hydrocracking is particularly important for converting heavy crude oils and residues into high-quality fuels. Both processes are essential for modern refineries to produce cleaner, more efficient fuels. The catalysts used in these processes are typically composed of metals like nickel, cobalt, molybdenum, and tungsten, supported on materials like alumina or silica. These catalysts are designed to withstand the harsh conditions of the refining processes and to maximize the conversion of impurities and heavy hydrocarbons into valuable products. The continuous development and improvement of these catalysts are crucial for the efficiency and effectiveness of hydrotreating and hydrocracking processes.

Diesel Hydrotreat, Lube Oils, Naphtha, Residue Upgrading, Others in the Global Hydro-processing Catalysts Market:

The Global Hydro-processing Catalysts Market finds extensive usage in various areas, including diesel hydrotreating, lube oils, naphtha, residue upgrading, and others. In diesel hydrotreating, the catalysts are used to remove sulfur and other impurities from diesel fuel, ensuring that it meets stringent environmental regulations and performs efficiently in engines. This process is crucial for producing ultra-low sulfur diesel (ULSD), which is essential for reducing emissions and improving air quality. In the production of lube oils, hydro-processing catalysts are used to remove impurities and improve the quality of the base oils. This process enhances the performance and longevity of lubricants, making them suitable for use in various industrial and automotive applications. Naphtha, a key feedstock for petrochemical production, also undergoes hydrotreating to remove contaminants and improve its quality. This process is essential for producing high-quality petrochemical products, including plastics, synthetic fibers, and other chemicals. Residue upgrading is another critical application of hydro-processing catalysts. In this process, heavy residues from crude oil refining are converted into lighter, more valuable products like gasoline, diesel, and jet fuel. This process helps refineries maximize the value of their crude oil feedstock and produce a wider range of high-quality fuels. Other applications of hydro-processing catalysts include the treatment of various petroleum fractions to remove impurities and improve their quality. These catalysts play a vital role in ensuring that petroleum products meet stringent environmental and performance standards.

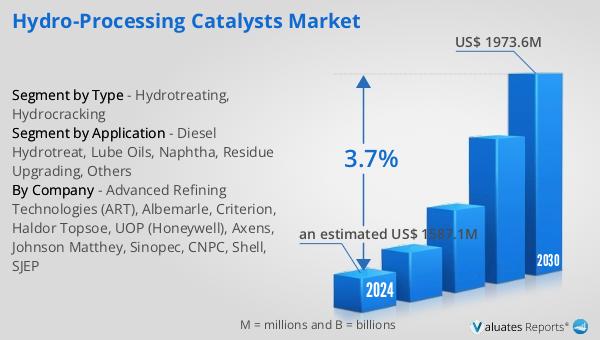

Global Hydro-processing Catalysts Market Outlook:

The global Hydro-processing Catalysts market is anticipated to grow from an estimated US$ 1587.1 million in 2024 to US$ 1973.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.7% during the forecast period. The market is dominated by the top three companies, which collectively hold about 62% of the market share. North America represents the largest market, accounting for approximately 32% of the total market share, followed closely by Europe, which holds around 29%. This growth is driven by the increasing demand for cleaner fuels and the implementation of stringent environmental regulations aimed at reducing emissions. The continuous development and improvement of hydro-processing catalysts are crucial for the efficiency and effectiveness of refining processes, ensuring that petroleum products meet stringent environmental and performance standards. The market is characterized by continuous innovation and development to improve catalyst efficiency and lifespan, driven by advancements in refining technologies and the rising need for high-quality fuels.

| Report Metric | Details |

| Report Name | Hydro-processing Catalysts Market |

| Accounted market size in 2024 | an estimated US$ 1587.1 million |

| Forecasted market size in 2030 | US$ 1973.6 million |

| CAGR | 3.7% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Advanced Refining Technologies (ART), Albemarle, Criterion, Haldor Topsoe, UOP (Honeywell), Axens, Johnson Matthey, Sinopec, CNPC, Shell, SJEP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |