What is Global Fluted Plastic Board Market?

The Global Fluted Plastic Board Market refers to the worldwide industry involved in the production, distribution, and utilization of fluted plastic boards. These boards are lightweight, durable, and versatile, making them suitable for a variety of applications. Fluted plastic boards are typically made from polypropylene or polyethylene and feature a corrugated structure that provides strength and rigidity. They are widely used in industries such as packaging, construction, automotive, and agriculture due to their resistance to moisture, chemicals, and impact. The market for these boards is expanding as businesses and consumers seek sustainable and cost-effective alternatives to traditional materials like wood and metal. The growth of e-commerce, increased demand for efficient packaging solutions, and the need for durable signage and display materials are some of the key factors driving the market. Additionally, the recyclability of fluted plastic boards aligns with global sustainability trends, further boosting their adoption across various sectors.

Polypropylene Type, Polyethylene Type, Others in the Global Fluted Plastic Board Market:

Polypropylene type fluted plastic boards are among the most popular in the Global Fluted Plastic Board Market. Polypropylene is a thermoplastic polymer known for its toughness, chemical resistance, and versatility. These boards are lightweight yet strong, making them ideal for a wide range of applications. They are often used in packaging, where their durability and resistance to moisture and chemicals are crucial. Polypropylene boards are also favored in the construction industry for temporary structures, protective barriers, and insulation. Their ability to be easily cut, shaped, and printed on makes them suitable for signage and display purposes as well. On the other hand, polyethylene type fluted plastic boards are known for their excellent impact resistance and flexibility. Polyethylene is another thermoplastic polymer that is widely used in various industries. These boards are particularly useful in applications where flexibility and impact resistance are essential, such as in automotive components, protective packaging, and agricultural uses. Polyethylene boards are also resistant to UV radiation, making them suitable for outdoor applications. In addition to polypropylene and polyethylene, there are other types of fluted plastic boards made from different materials. These include boards made from polycarbonate, PVC, and other specialized polymers. Each of these materials offers unique properties that cater to specific needs. For instance, polycarbonate boards are known for their high impact resistance and optical clarity, making them suitable for applications that require transparency and durability. PVC boards, on the other hand, are known for their excellent chemical resistance and fire retardant properties, making them ideal for use in harsh environments. The diversity of materials used in the production of fluted plastic boards allows for a wide range of applications and ensures that there is a suitable option for almost any requirement.

Graphic Arts and Signage, Packaging and Storage, Agriculture, Automotive, Building and Construction, Others in the Global Fluted Plastic Board Market:

The usage of Global Fluted Plastic Board Market spans across various industries, each benefiting from the unique properties of these boards. In the graphic arts and signage industry, fluted plastic boards are widely used for creating durable and eye-catching signs, displays, and promotional materials. Their lightweight nature makes them easy to transport and install, while their ability to be printed on directly ensures high-quality graphics. In the packaging and storage sector, fluted plastic boards are used to create robust and reusable packaging solutions. They provide excellent protection for goods during transit and storage, thanks to their impact resistance and moisture-proof properties. These boards are also used to create custom packaging solutions for delicate or high-value items. In agriculture, fluted plastic boards are used for a variety of purposes, including creating protective barriers, plant guards, and temporary structures. Their resistance to moisture and chemicals makes them ideal for use in harsh outdoor environments. In the automotive industry, fluted plastic boards are used to create lightweight and durable components, such as trunk liners, door panels, and protective covers. Their impact resistance and flexibility make them suitable for use in various parts of a vehicle. In the building and construction industry, fluted plastic boards are used for temporary structures, protective barriers, and insulation. Their lightweight nature makes them easy to handle and install, while their durability ensures they can withstand the rigors of a construction site. Other industries that benefit from the use of fluted plastic boards include the electronics industry, where they are used for creating protective packaging for sensitive components, and the medical industry, where they are used for creating hygienic and durable surfaces. The versatility and durability of fluted plastic boards make them a valuable material in a wide range of applications.

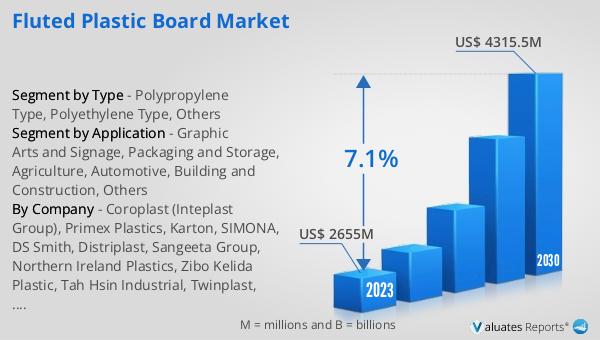

Global Fluted Plastic Board Market Outlook:

The global Fluted Plastic Board market is anticipated to grow significantly, with projections estimating it will reach US$ 4315.5 million by 2030, up from an estimated US$ 2859.5 million in 2024, reflecting a compound annual growth rate (CAGR) of 7.1% during the period from 2024 to 2030. The market is characterized by a competitive landscape, with the top three players holding approximately 10% of the global market share. Among the different types of fluted plastic boards, the Polyethylene type dominates the market, accounting for about 85% of the total share. This type is particularly favored due to its excellent impact resistance and flexibility, making it suitable for a wide range of applications. In terms of application, the Packaging and Storage sector is the largest, holding around 50% of the market share. This is largely due to the increasing demand for durable, reusable, and moisture-resistant packaging solutions in various industries. The growth of e-commerce and the need for efficient packaging solutions to protect goods during transit and storage are key factors driving the demand in this sector. Overall, the market outlook for fluted plastic boards is positive, with significant growth expected in the coming years.

| Report Metric | Details |

| Report Name | Fluted Plastic Board Market |

| Accounted market size in 2024 | an estimated US$ 2859.5 million |

| Forecasted market size in 2030 | US$ 4315.5 million |

| CAGR | 7.1% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Coroplast (Inteplast Group), Primex Plastics, Karton, SIMONA, DS Smith, Distriplast, Sangeeta Group, Northern Ireland Plastics, Zibo Kelida Plastic, Tah Hsin Industrial, Twinplast, Plastflute, Creabuild, Corex Plastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |