What is Global Flange Sealing Market?

The Global Flange Sealing Market refers to the industry that produces and supplies flange seals, which are essential components used to prevent leaks in piping systems. Flange seals are used to join two sections of pipe or other cylindrical objects, ensuring a tight seal to prevent the escape of liquids or gases. These seals are critical in various industries, including oil and gas, chemical, power, and municipal infrastructure, where maintaining the integrity of piping systems is crucial for safety and efficiency. The market encompasses a wide range of products, including metallic, semi-metallic, and non-metallic flange seals, each designed to meet specific requirements and operating conditions. The demand for flange seals is driven by the need for reliable and durable sealing solutions in industries that handle hazardous or high-pressure substances. As industrial activities continue to grow globally, the need for effective flange sealing solutions is expected to rise, making this market an essential component of the broader industrial supply chain.

Metallic Types, Semi-Metallic Types, Non-Metallic Types in the Global Flange Sealing Market:

Flange seals come in various types, each with unique characteristics and applications. Metallic flange seals are made from metals such as stainless steel, copper, and aluminum. These seals are known for their high strength, durability, and resistance to extreme temperatures and pressures. They are commonly used in industries where the operating conditions are harsh, such as the oil and gas industry, where they can withstand the high pressures and temperatures associated with drilling and extraction processes. Metallic seals are also used in the power industry, where they help maintain the integrity of high-pressure steam systems. Semi-metallic flange seals combine the strength of metals with the flexibility of non-metallic materials. These seals typically consist of a metal core surrounded by a non-metallic outer layer, such as graphite or PTFE (polytetrafluoroethylene). This combination provides a balance of strength and flexibility, making semi-metallic seals suitable for a wide range of applications. They are often used in the chemical industry, where they can resist the corrosive effects of various chemicals while maintaining a tight seal. Non-metallic flange seals are made entirely from non-metallic materials, such as rubber, PTFE, or graphite. These seals are known for their excellent chemical resistance and flexibility, making them ideal for applications where the sealing material needs to conform to irregular surfaces or where chemical compatibility is a concern. Non-metallic seals are commonly used in municipal infrastructure projects, such as water and wastewater treatment plants, where they help prevent leaks in piping systems that transport water and other fluids. Each type of flange seal has its advantages and limitations, and the choice of seal depends on the specific requirements of the application, including the operating conditions, the nature of the substances being transported, and the need for durability and reliability.

Oil and Gas Industry, Chemical Industry, Power Industry, Municipal Infrastructure, Others in the Global Flange Sealing Market:

The Global Flange Sealing Market finds extensive usage across various industries due to its critical role in ensuring the integrity and safety of piping systems. In the oil and gas industry, flange seals are essential for preventing leaks in pipelines that transport crude oil, natural gas, and refined products. The high pressures and temperatures involved in drilling, extraction, and refining processes require robust sealing solutions, making metallic and semi-metallic flange seals particularly suitable for these applications. In the chemical industry, flange seals are used to prevent leaks in pipelines that carry corrosive chemicals and other hazardous substances. The chemical resistance of non-metallic and semi-metallic seals makes them ideal for this industry, where maintaining a tight seal is crucial to prevent environmental contamination and ensure the safety of workers. The power industry also relies heavily on flange seals to maintain the integrity of high-pressure steam systems and other critical infrastructure. Metallic seals are often used in power plants to withstand the extreme temperatures and pressures associated with steam generation and distribution. In municipal infrastructure projects, such as water and wastewater treatment plants, flange seals are used to prevent leaks in pipelines that transport water and other fluids. Non-metallic seals are commonly used in these applications due to their flexibility and chemical resistance. Other industries that use flange seals include food and beverage, pharmaceuticals, and manufacturing, where maintaining a tight seal is essential for ensuring product quality and safety. The versatility and reliability of flange seals make them indispensable components in a wide range of industrial applications, contributing to the overall efficiency and safety of piping systems.

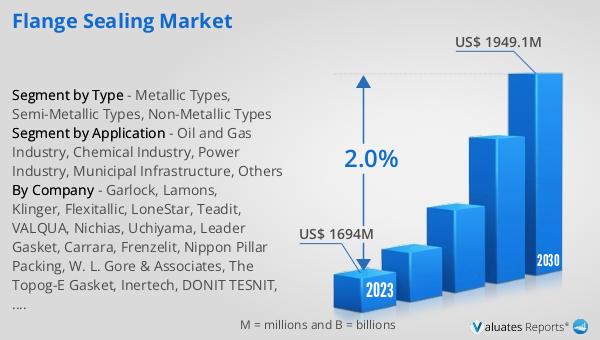

Global Flange Sealing Market Outlook:

The global Flange Sealing market is anticipated to grow significantly, with projections indicating it will reach US$ 1949.1 million by 2030, up from an estimated US$ 1730.8 million in 2024, reflecting a compound annual growth rate (CAGR) of 2.0% during the period from 2024 to 2030. The market is dominated by the top three players, who collectively account for approximately 30% of the total global market share. The Asia-Pacific (APAC) region is the largest consumer market for flange sealing products, accounting for about 36% of the global demand, followed by North America and Europe. This growth is driven by the increasing industrial activities and infrastructure development in these regions, which in turn boosts the demand for reliable and durable flange sealing solutions. The market's expansion is also supported by advancements in sealing technologies and the development of new materials that enhance the performance and longevity of flange seals. As industries continue to prioritize safety and efficiency, the demand for high-quality flange sealing products is expected to remain strong, making this market a vital component of the global industrial landscape.

| Report Metric | Details |

| Report Name | Flange Sealing Market |

| Accounted market size in 2024 | an estimated US$ 1730.8 million |

| Forecasted market size in 2030 | US$ 1949.1 million |

| CAGR | 2.0% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Garlock, Lamons, Klinger, Flexitallic, LoneStar, Teadit, VALQUA, Nichias, Uchiyama, Leader Gasket, Carrara, Frenzelit, Nippon Pillar Packing, W. L. Gore & Associates, The Topog-E Gasket, Inertech, DONIT TESNIT, Temac, Double Peaks Graphite Sealing Materials, Binyang Special Packing, ZONDE Sealing & Gasket |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |