What is Global Blow Fill Seal Packaging Machineries Market?

The Global Blow Fill Seal (BFS) Packaging Machineries Market is a specialized segment within the packaging industry that focuses on the production of machinery used for the blow-fill-seal process. This process is an advanced aseptic packaging technology that forms, fills, and seals containers in a continuous, automated system. The BFS technology is primarily used for packaging liquid and semi-liquid products, ensuring high levels of sterility and reducing the risk of contamination. The market for BFS packaging machineries is driven by the increasing demand for safe and efficient packaging solutions in various industries, including pharmaceuticals, food and beverages, and personal care. The technology is particularly valued for its ability to produce single-dose units, which are essential for maintaining product integrity and dosage accuracy. As regulatory standards for packaging and product safety become more stringent, the adoption of BFS technology is expected to grow, further propelling the market. The BFS packaging machineries market is characterized by continuous innovation, with manufacturers focusing on enhancing machine efficiency, reducing operational costs, and improving product quality.

Rotary Machine, Shuttling Machine in the Global Blow Fill Seal Packaging Machineries Market:

Rotary and shuttling machines are two primary types of machinery used in the Global Blow Fill Seal Packaging Machineries Market. Rotary machines operate on a continuous motion principle, where the mold rotates around a central axis. This type of machine is highly efficient and capable of producing a large number of units in a short period. The continuous motion ensures that the process of blowing, filling, and sealing happens simultaneously, which significantly reduces cycle time and increases productivity. Rotary machines are particularly suitable for high-volume production environments where speed and efficiency are critical. On the other hand, shuttling machines operate on an intermittent motion principle. In this type of machine, the mold moves back and forth between different stations for blowing, filling, and sealing. While shuttling machines may have a slower cycle time compared to rotary machines, they offer greater flexibility and precision. This makes them ideal for applications where customization and accuracy are more important than sheer volume. Shuttling machines are often used for smaller production runs or for products that require specific handling and packaging conditions. Both types of machines have their unique advantages and are chosen based on the specific needs of the production process. The choice between rotary and shuttling machines depends on factors such as production volume, product type, and desired level of automation. Manufacturers in the BFS packaging machineries market continuously innovate to improve the performance and capabilities of both rotary and shuttling machines. This includes advancements in machine design, materials, and control systems to enhance efficiency, reduce downtime, and ensure consistent product quality. As the demand for BFS technology grows, the market for both rotary and shuttling machines is expected to expand, driven by the need for reliable and efficient packaging solutions.

Medical Institutions, Research Institutes, Pharmaceutical Company, Others in the Global Blow Fill Seal Packaging Machineries Market:

The usage of Global Blow Fill Seal Packaging Machineries Market extends across various sectors, including medical institutions, research institutes, pharmaceutical companies, and others. In medical institutions, BFS technology is crucial for packaging sterile solutions, such as saline, dextrose, and other intravenous fluids. The aseptic nature of the BFS process ensures that these solutions remain free from contaminants, which is vital for patient safety. Medical institutions rely on BFS packaging to provide single-dose units that are easy to administer and reduce the risk of dosage errors. Research institutes also benefit from BFS technology, particularly in the development and testing of new drugs and formulations. The ability to produce small, sterile batches of experimental drugs allows researchers to conduct clinical trials with greater accuracy and reliability. BFS packaging ensures that the integrity of the experimental drugs is maintained throughout the testing process. Pharmaceutical companies are perhaps the largest users of BFS packaging machineries. The technology is used to package a wide range of pharmaceutical products, including vaccines, eye drops, inhalation solutions, and oral liquids. The BFS process provides a high level of sterility, which is essential for maintaining the efficacy and safety of pharmaceutical products. Additionally, the ability to produce single-dose units helps pharmaceutical companies comply with regulatory requirements and improve patient adherence to medication regimens. Other industries, such as food and beverages and personal care, also utilize BFS packaging machineries. In the food and beverage industry, BFS technology is used to package products like juices, dairy products, and sauces, ensuring that they remain fresh and free from contaminants. In the personal care industry, BFS packaging is used for products like shampoos, lotions, and liquid soaps, providing convenient and hygienic packaging solutions. Overall, the versatility and reliability of BFS packaging machineries make them an essential tool across various industries, driving the growth and adoption of this technology.

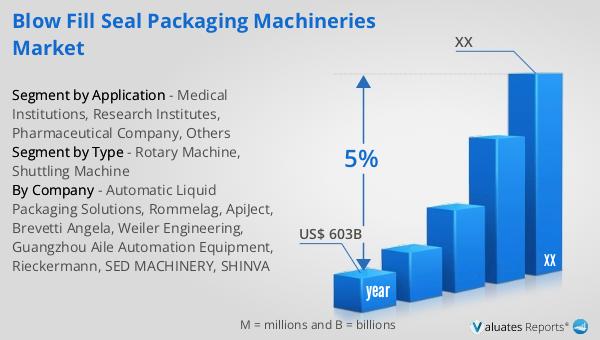

Global Blow Fill Seal Packaging Machineries Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This significant market size underscores the increasing demand for medical devices worldwide, driven by factors such as an aging population, advancements in medical technology, and the rising prevalence of chronic diseases. The steady growth rate reflects the ongoing innovation and development within the medical device industry, as companies strive to meet the evolving needs of healthcare providers and patients. The expansion of the medical device market also highlights the importance of regulatory compliance and quality assurance, as manufacturers must adhere to stringent standards to ensure the safety and efficacy of their products. As the market continues to grow, there will be increased opportunities for companies to introduce new and improved medical devices, enhancing patient care and outcomes. The projected growth of the medical device market is a testament to the critical role that these devices play in modern healthcare, from diagnostic tools and surgical instruments to advanced imaging systems and wearable health monitors.

| Report Metric | Details |

| Report Name | Blow Fill Seal Packaging Machineries Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Automatic Liquid Packaging Solutions, Rommelag, ApiJect, Brevetti Angela, Weiler Engineering, Guangzhou Aile Automation Equipment, Rieckermann, SED MACHINERY, SHINVA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |