What is Global Automatic Wire Wedge Bonder Equipment Market?

The Global Automatic Wire Wedge Bonder Equipment Market refers to the industry that manufactures and sells machines used for wire bonding in semiconductor devices. Wire bonding is a method of making interconnections between a semiconductor device (such as an integrated circuit or transistor) and its packaging during the manufacturing process. The equipment used for this purpose is highly specialized and automated to ensure precision and efficiency. These machines are crucial in the production of various electronic components, including microchips, sensors, and other semiconductor devices. The market for this equipment is driven by the growing demand for electronic devices, advancements in semiconductor technology, and the need for high-quality, reliable interconnections in electronic products. As technology continues to evolve, the demand for more sophisticated and efficient wire bonding equipment is expected to increase, making this market an essential part of the semiconductor manufacturing industry.

Fully Automatic, Semi-automatic in the Global Automatic Wire Wedge Bonder Equipment Market:

In the Global Automatic Wire Wedge Bonder Equipment Market, there are two main types of equipment: fully automatic and semi-automatic. Fully automatic wire wedge bonders are designed to perform the entire bonding process without human intervention. These machines are equipped with advanced sensors, software, and robotic arms that can precisely place and bond wires at high speeds. They are ideal for high-volume production environments where consistency and speed are critical. Fully automatic bonders can handle complex bonding tasks, including fine-pitch bonding and multi-tier bonding, making them suitable for advanced semiconductor devices. On the other hand, semi-automatic wire wedge bonders require some level of human involvement. While they still offer a high degree of automation, operators are needed to load and unload components, and sometimes to assist with alignment and positioning. Semi-automatic bonders are often used in smaller production runs or in research and development settings where flexibility and adaptability are more important than sheer speed. Both types of equipment play a vital role in the semiconductor manufacturing process, but the choice between fully automatic and semi-automatic bonders depends on the specific needs and scale of the production operation.

Integrated Device Manufacturers (IDMs), Outsourced Semiconductor Assembly and Test (OSAT) in the Global Automatic Wire Wedge Bonder Equipment Market:

The usage of Global Automatic Wire Wedge Bonder Equipment Market in Integrated Device Manufacturers (IDMs) and Outsourced Semiconductor Assembly and Test (OSAT) companies is crucial for the production of semiconductor devices. IDMs are companies that design, manufacture, and sell their semiconductor products. They rely heavily on automatic wire wedge bonders to ensure the quality and reliability of their products. These machines enable IDMs to produce high-performance semiconductor devices with precise and consistent wire bonds. The automation provided by these bonders helps IDMs to achieve high production yields and reduce manufacturing costs. In addition, the advanced capabilities of fully automatic bonders allow IDMs to keep up with the latest technological advancements and meet the increasing demand for more sophisticated electronic devices. On the other hand, OSAT companies specialize in providing assembly and testing services for semiconductor manufacturers. They use automatic wire wedge bonders to assemble and test semiconductor devices for their clients. The use of these machines allows OSAT companies to offer high-quality assembly and testing services, ensuring that the semiconductor devices meet the required specifications and performance standards. The automation and precision provided by these bonders help OSAT companies to achieve high throughput and efficiency, enabling them to handle large volumes of semiconductor devices. Overall, the usage of automatic wire wedge bonders in both IDMs and OSAT companies is essential for the production of high-quality semiconductor devices and the overall success of the semiconductor industry.

Global Automatic Wire Wedge Bonder Equipment Market Outlook:

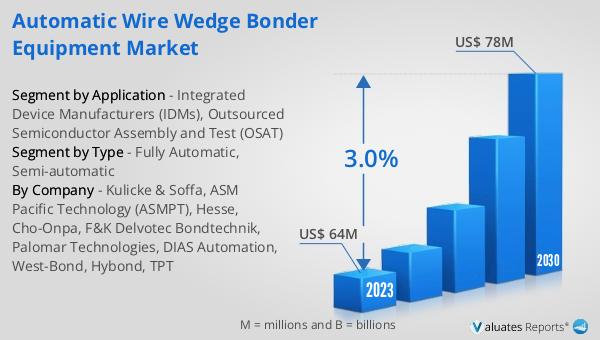

The global Automatic Wire Wedge Bonder Equipment market was valued at US$ 64 million in 2023 and is anticipated to reach US$ 78 million by 2030, witnessing a CAGR of 3.0% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for semiconductor devices and the need for advanced manufacturing equipment. The growth in the market can be attributed to several factors, including the rising adoption of electronic devices, advancements in semiconductor technology, and the need for high-quality interconnections in electronic products. As the demand for more sophisticated and efficient wire bonding equipment continues to rise, the market is expected to experience sustained growth over the forecast period. The increasing investments in research and development, along with the growing focus on automation and precision in semiconductor manufacturing, are also expected to contribute to the market's growth. Overall, the market outlook for the global Automatic Wire Wedge Bonder Equipment market is positive, with steady growth expected over the coming years.

| Report Metric | Details |

| Report Name | Automatic Wire Wedge Bonder Equipment Market |

| Accounted market size in 2023 | US$ 64 million |

| Forecasted market size in 2030 | US$ 78 million |

| CAGR | 3.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kulicke & Soffa, ASM Pacific Technology (ASMPT), Hesse, Cho-Onpa, F&K Delvotec Bondtechnik, Palomar Technologies, DIAS Automation, West-Bond, Hybond, TPT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |