What is Global Automatic Ultrasonic Flaw Detector Market?

The Global Automatic Ultrasonic Flaw Detector Market is a specialized segment within the broader non-destructive testing (NDT) industry. This market focuses on devices that utilize ultrasonic waves to detect flaws or defects in materials without causing any damage. These detectors are essential in various industries where the integrity of materials is critical, such as aerospace, automotive, oil and gas, and energy. The technology works by sending high-frequency sound waves into a material and then analyzing the reflected waves to identify any inconsistencies or defects. The global market for these devices is driven by the increasing demand for high-quality materials and the need for stringent safety standards across industries. As industries continue to evolve and adopt more advanced technologies, the demand for automatic ultrasonic flaw detectors is expected to grow, making it a crucial component in ensuring the safety and reliability of materials used in critical applications.

Portable, Benchtop in the Global Automatic Ultrasonic Flaw Detector Market:

In the Global Automatic Ultrasonic Flaw Detector Market, devices can be broadly categorized into portable and benchtop models. Portable ultrasonic flaw detectors are designed for on-the-go inspections and are typically lightweight, compact, and battery-operated. These devices are ideal for fieldwork, allowing technicians to perform inspections in remote or hard-to-reach locations. They are commonly used in industries such as oil and gas, where pipelines and other infrastructure may be spread over vast areas. Portable models offer the flexibility to conduct inspections without the need for a fixed setup, making them highly versatile and convenient for various applications. On the other hand, benchtop ultrasonic flaw detectors are larger, more robust systems designed for laboratory or industrial environments where detailed and high-precision inspections are required. These models are often equipped with advanced features such as higher resolution displays, more powerful signal processing capabilities, and the ability to handle larger and more complex inspection tasks. Benchtop models are typically used in industries like aerospace and automotive, where the quality and integrity of materials are of utmost importance. They provide a stable and controlled environment for conducting thorough inspections, ensuring that even the smallest defects are detected. Both portable and benchtop ultrasonic flaw detectors play a crucial role in maintaining the safety and reliability of materials used in various industries. The choice between the two depends on the specific requirements of the inspection task, with portable models offering flexibility and convenience, while benchtop models provide precision and advanced capabilities. As technology continues to advance, both types of detectors are expected to become more sophisticated, offering even greater accuracy and efficiency in flaw detection.

Energy, Aerospace, Oil & Gas, Automotive, Others in the Global Automatic Ultrasonic Flaw Detector Market:

The Global Automatic Ultrasonic Flaw Detector Market finds extensive usage across various industries, including energy, aerospace, oil and gas, automotive, and others. In the energy sector, these detectors are crucial for inspecting components such as turbines, generators, and pipelines. Ensuring the integrity of these components is vital for preventing failures that could lead to costly downtime or catastrophic accidents. In the aerospace industry, ultrasonic flaw detectors are used to inspect aircraft components, including wings, fuselage, and engines. The high safety standards in this industry necessitate the use of advanced inspection technologies to detect even the smallest defects that could compromise the structural integrity of an aircraft. In the oil and gas industry, ultrasonic flaw detectors are employed to inspect pipelines, storage tanks, and other infrastructure. The harsh operating conditions and the critical nature of these assets make regular inspections essential for preventing leaks, spills, and other incidents. In the automotive industry, these detectors are used to inspect components such as engine parts, chassis, and suspension systems. Ensuring the quality and reliability of these components is crucial for vehicle safety and performance. Other industries that utilize ultrasonic flaw detectors include manufacturing, construction, and railways. In manufacturing, these devices are used to inspect raw materials and finished products to ensure they meet quality standards. In construction, they are used to inspect structural components such as beams and columns to ensure they are free from defects that could compromise the safety of a building. In the railway industry, ultrasonic flaw detectors are used to inspect tracks and other infrastructure to prevent accidents caused by material failures. Overall, the use of automatic ultrasonic flaw detectors is essential for maintaining the safety, reliability, and performance of critical components across various industries.

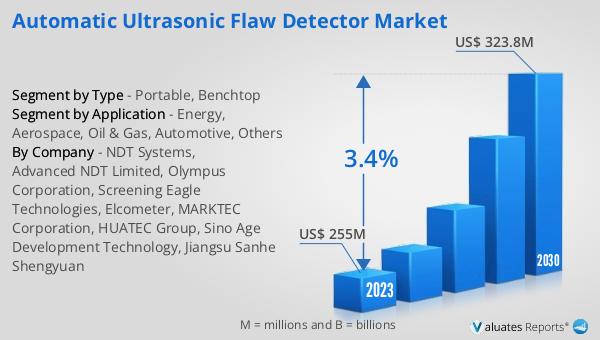

Global Automatic Ultrasonic Flaw Detector Market Outlook:

The global Automatic Ultrasonic Flaw Detector market was valued at US$ 255 million in 2023 and is anticipated to reach US$ 323.8 million by 2030, witnessing a CAGR of 3.4% during the forecast period from 2024 to 2030. The market is characterized by the dominance of a few key players, with the top five manufacturers accounting for over 54% of the global market share. This concentration of market power indicates a competitive landscape where leading companies leverage their technological advancements, extensive distribution networks, and strong customer relationships to maintain their market positions. The steady growth rate reflects the increasing demand for high-quality materials and stringent safety standards across various industries. As industries continue to evolve and adopt more advanced technologies, the demand for automatic ultrasonic flaw detectors is expected to grow, making it a crucial component in ensuring the safety and reliability of materials used in critical applications.

| Report Metric | Details |

| Report Name | Automatic Ultrasonic Flaw Detector Market |

| Accounted market size in 2023 | US$ 255 million |

| Forecasted market size in 2030 | US$ 323.8 million |

| CAGR | 3.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NDT Systems, Advanced NDT Limited, Olympus Corporation, Screening Eagle Technologies, Elcometer, MARKTEC Corporation, HUATEC Group, Sino Age Development Technology, Jiangsu Sanhe Shengyuan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |