What is Global Automatic Grease Lubrication System Market?

The Global Automatic Grease Lubrication System Market is a specialized segment within the broader lubrication systems industry. These systems are designed to automatically supply precise amounts of grease to various machinery components, ensuring optimal performance and longevity. The market encompasses a wide range of industries, including construction, transportation, manufacturing, and maintenance. Automatic grease lubrication systems are essential for reducing friction and wear in machinery, thereby minimizing downtime and maintenance costs. They are particularly valuable in environments where manual lubrication is challenging or impractical. The systems can be customized to meet the specific needs of different applications, making them versatile and highly efficient. As industries continue to prioritize operational efficiency and equipment reliability, the demand for automatic grease lubrication systems is expected to grow. These systems not only enhance the performance of machinery but also contribute to overall cost savings by extending the lifespan of equipment and reducing the frequency of repairs.

Single-line Lubrication Systems, Dual-line Lubrication Systems, Multi-line Lubrication Systems, Other in the Global Automatic Grease Lubrication System Market:

Single-line lubrication systems are among the most commonly used types in the Global Automatic Grease Lubrication System Market. These systems are designed to deliver grease to multiple lubrication points from a single pump. They are highly efficient and easy to install, making them ideal for a wide range of applications. Single-line systems are particularly useful in environments where space is limited, as they require minimal piping and can be easily integrated into existing machinery. Dual-line lubrication systems, on the other hand, are designed for more demanding applications. These systems use two main lines to deliver grease, ensuring that even if one line is blocked, the other can continue to supply lubrication. This redundancy makes dual-line systems highly reliable and suitable for heavy-duty applications such as mining and construction. Multi-line lubrication systems are another important category within the market. These systems use multiple pumps to deliver grease to different lubrication points, allowing for greater flexibility and control. Multi-line systems are ideal for complex machinery with numerous lubrication points, as they can be easily customized to meet specific requirements. Other types of lubrication systems in the market include progressive systems and circulating oil systems. Progressive systems use a series of metering valves to deliver precise amounts of grease to each lubrication point, ensuring even distribution. Circulating oil systems, on the other hand, continuously circulate oil through the machinery, providing constant lubrication and cooling. Each type of lubrication system has its own advantages and is suited to different applications, making the Global Automatic Grease Lubrication System Market diverse and dynamic.

Construction Machinery, Transportation/Vehicles, Industrial & Manufacturing Equipments, Maintenance Market, Other in the Global Automatic Grease Lubrication System Market:

The usage of Global Automatic Grease Lubrication System Market spans across various sectors, each with its unique requirements and challenges. In the construction machinery sector, these systems are crucial for maintaining the performance and longevity of heavy equipment such as excavators, bulldozers, and cranes. Construction machinery operates in harsh environments with high levels of dust and debris, making regular lubrication essential to prevent wear and tear. Automatic grease lubrication systems ensure that these machines receive consistent lubrication, reducing downtime and maintenance costs. In the transportation and vehicles sector, automatic grease lubrication systems are used in trucks, buses, and other commercial vehicles. These systems help to maintain the performance of critical components such as bearings, axles, and joints, ensuring smooth operation and reducing the risk of breakdowns. In industrial and manufacturing equipment, automatic grease lubrication systems are used to maintain the performance of machinery such as conveyors, presses, and pumps. These systems help to reduce friction and wear, extending the lifespan of the equipment and improving overall efficiency. In the maintenance market, automatic grease lubrication systems are used to service a wide range of machinery and equipment. These systems help to ensure that all lubrication points receive the correct amount of grease, reducing the risk of over-lubrication or under-lubrication. Other sectors that use automatic grease lubrication systems include agriculture, marine, and aerospace. In agriculture, these systems are used to maintain the performance of tractors, harvesters, and other farming equipment. In the marine sector, automatic grease lubrication systems are used to maintain the performance of ship engines and other critical components. In aerospace, these systems are used to maintain the performance of aircraft components, ensuring safe and reliable operation. Overall, the usage of automatic grease lubrication systems is essential for maintaining the performance and longevity of machinery and equipment across various sectors.

Global Automatic Grease Lubrication System Market Outlook:

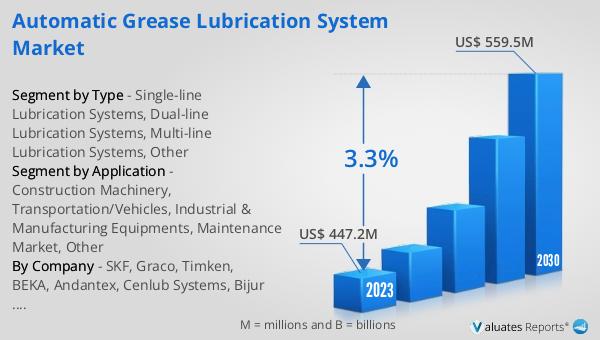

The global Automatic Grease Lubrication System market was valued at US$ 447.2 million in 2023 and is anticipated to reach US$ 559.5 million by 2030, witnessing a CAGR of 3.3% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for efficient and reliable lubrication solutions across various industries. The growth is attributed to the rising awareness about the benefits of automatic lubrication systems, such as reduced maintenance costs, improved equipment performance, and extended machinery lifespan. As industries continue to prioritize operational efficiency and equipment reliability, the demand for automatic grease lubrication systems is expected to grow. These systems not only enhance the performance of machinery but also contribute to overall cost savings by extending the lifespan of equipment and reducing the frequency of repairs. The market is also driven by technological advancements in lubrication systems, which have led to the development of more efficient and reliable solutions. As a result, the Global Automatic Grease Lubrication System Market is expected to witness significant growth in the coming years.

| Report Metric | Details |

| Report Name | Automatic Grease Lubrication System Market |

| Accounted market size in 2023 | US$ 447.2 million |

| Forecasted market size in 2030 | US$ 559.5 million |

| CAGR | 3.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SKF, Graco, Timken, BEKA, Andantex, Cenlub Systems, Bijur delimon, Groeneveld Group, Lubecore, Lubrite Industries, Oil-Rite, Pricol |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |