What is Global Aseptic Paper for Pharmaceuticals Packaging Market?

The Global Aseptic Paper for Pharmaceuticals Packaging Market refers to the industry focused on producing and utilizing aseptic paper materials specifically designed for packaging pharmaceutical products. Aseptic paper is a type of packaging material that ensures the sterility and safety of pharmaceutical products by preventing contamination from microorganisms. This market is crucial for maintaining the integrity and efficacy of medications, vaccines, and other pharmaceutical products during storage and transportation. The aseptic paper used in this market is typically composed of multiple layers, including paperboard, polyethylene, and aluminum foil, which work together to create a barrier against light, oxygen, and moisture. This type of packaging is essential for extending the shelf life of pharmaceutical products and ensuring they remain safe and effective for patients. The Global Aseptic Paper for Pharmaceuticals Packaging Market is driven by the increasing demand for safe and reliable packaging solutions in the pharmaceutical industry, as well as the growing awareness of the importance of maintaining product sterility.

Aseptic Paper up to 100 microns, Aseptic Paper from 100 to 200 microns, Aseptic Paper from 200 to 300 microns, Aseptic Paper above 300 microns in the Global Aseptic Paper for Pharmaceuticals Packaging Market:

Aseptic paper used in the Global Aseptic Paper for Pharmaceuticals Packaging Market comes in various thicknesses, each serving different purposes and offering unique benefits. Aseptic paper up to 100 microns is typically used for lightweight packaging applications where flexibility and ease of handling are essential. This type of paper is often used for packaging small pharmaceutical products, such as tablets and capsules, where the primary concern is protecting the product from contamination while maintaining a lightweight and cost-effective solution. Aseptic paper from 100 to 200 microns is more robust and provides additional protection against physical damage and environmental factors. This thickness is suitable for packaging larger pharmaceutical products, such as syringes and vials, where additional durability is required to prevent breakage and ensure the product remains sterile. Aseptic paper from 200 to 300 microns offers even greater protection and is often used for packaging bulk pharmaceutical products or those that require a higher level of barrier protection. This thickness is ideal for products that are sensitive to light, oxygen, and moisture, as it provides a more substantial barrier to these elements. Aseptic paper above 300 microns is the thickest and most durable option available in the market. This type of paper is used for packaging high-value pharmaceutical products that require the highest level of protection against contamination and environmental factors. It is also used for packaging products that need to be transported over long distances or stored for extended periods, as it provides the best barrier properties and ensures the product remains safe and effective throughout its shelf life. Each thickness of aseptic paper serves a specific purpose in the Global Aseptic Paper for Pharmaceuticals Packaging Market, and the choice of thickness depends on the specific requirements of the pharmaceutical product being packaged.

Dairy Products, Drinks, Instant Food, Other in the Global Aseptic Paper for Pharmaceuticals Packaging Market:

The usage of Global Aseptic Paper for Pharmaceuticals Packaging Market extends beyond pharmaceuticals and finds applications in various other areas, including dairy products, drinks, instant food, and other consumables. In the dairy industry, aseptic paper is used to package products such as milk, yogurt, and cheese. The aseptic packaging ensures that these dairy products remain fresh and free from contamination, extending their shelf life and maintaining their nutritional value. The multi-layered structure of aseptic paper provides a barrier against light, oxygen, and moisture, which are critical factors in preserving the quality of dairy products. In the beverage industry, aseptic paper is used for packaging drinks such as juices, soft drinks, and alcoholic beverages. The aseptic packaging helps maintain the flavor, color, and nutritional content of the drinks while preventing contamination from microorganisms. This is particularly important for products that do not contain preservatives and rely on aseptic packaging to ensure their safety and quality. In the instant food industry, aseptic paper is used to package products such as soups, sauces, and ready-to-eat meals. The aseptic packaging ensures that these products remain safe to consume and retain their flavor and nutritional value. The barrier properties of aseptic paper protect the instant food products from contamination and environmental factors, ensuring they remain fresh and ready to eat. Other applications of aseptic paper include packaging for cosmetics, personal care products, and medical devices. In these industries, aseptic packaging is essential for maintaining the sterility and safety of the products, ensuring they remain effective and safe for use. The versatility and effectiveness of aseptic paper make it a valuable packaging solution across various industries, providing a reliable barrier against contamination and environmental factors.

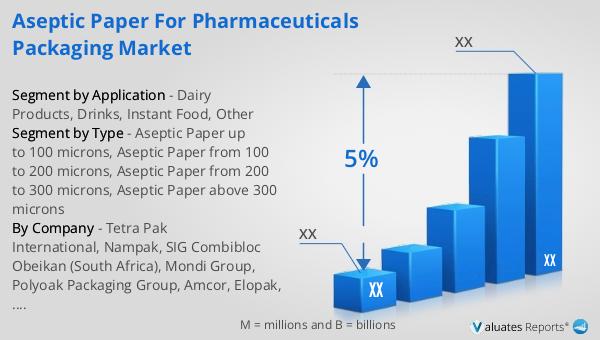

Global Aseptic Paper for Pharmaceuticals Packaging Market Outlook:

The global pharmaceutical market was valued at 1475 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market saw an increase from 1005 billion USD in 2018 to 1094 billion USD in 2022. This growth highlights the expanding demand for pharmaceutical products and the increasing importance of reliable and effective packaging solutions, such as aseptic paper, to ensure the safety and efficacy of these products. The steady growth in the pharmaceutical market underscores the need for innovative packaging solutions that can meet the stringent requirements of the industry and provide a high level of protection against contamination and environmental factors. As the pharmaceutical market continues to grow, the demand for aseptic paper for packaging is expected to rise, driven by the need for safe and reliable packaging solutions that can maintain the integrity and efficacy of pharmaceutical products.

| Report Metric | Details |

| Report Name | Aseptic Paper for Pharmaceuticals Packaging Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tetra Pak International, Nampak, SIG Combibloc Obeikan (South Africa), Mondi Group, Polyoak Packaging Group, Amcor, Elopak, IPI, Uflex, Ducart |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |