What is Global 3D Automated Optical Inspection (AOI) Market?

The Global 3D Automated Optical Inspection (AOI) Market is a rapidly growing sector within the electronics manufacturing industry. AOI systems are used to inspect electronic assemblies, such as printed circuit boards (PCBs), for defects and quality assurance. Unlike traditional 2D AOI systems, 3D AOI systems use advanced imaging technologies to capture three-dimensional data, allowing for more accurate and comprehensive inspections. These systems can detect a wide range of defects, including solder joint issues, component placement errors, and surface anomalies. The global market for 3D AOI is driven by the increasing complexity of electronic devices, the demand for higher quality standards, and the need for faster production cycles. As electronic components become smaller and more densely packed, the precision offered by 3D AOI systems becomes essential. Additionally, the integration of artificial intelligence and machine learning algorithms into AOI systems is enhancing their capabilities, making them more efficient and reliable. The market is also benefiting from the growing adoption of Industry 4.0 practices, which emphasize automation and data-driven decision-making in manufacturing processes. Overall, the Global 3D AOI Market is poised for significant growth as it continues to evolve and adapt to the changing needs of the electronics industry.

Inline 3D AOI, Offline 3D AOI in the Global 3D Automated Optical Inspection (AOI) Market:

Inline 3D AOI and Offline 3D AOI are two primary types of systems used in the Global 3D Automated Optical Inspection (AOI) Market. Inline 3D AOI systems are integrated directly into the production line, allowing for real-time inspection of electronic assemblies as they are being manufactured. These systems are highly efficient and can inspect a large number of units quickly, making them ideal for high-volume production environments. Inline 3D AOI systems use advanced imaging technologies, such as structured light or laser triangulation, to capture detailed 3D images of the assemblies. These images are then analyzed using sophisticated algorithms to detect any defects or anomalies. The real-time feedback provided by inline systems enables manufacturers to identify and address issues immediately, reducing the risk of defective products reaching the market. On the other hand, Offline 3D AOI systems are standalone units that are used to inspect electronic assemblies after they have been manufactured. These systems are typically used for batch inspections or for inspecting assemblies that require more detailed analysis. Offline 3D AOI systems offer greater flexibility in terms of inspection parameters and can be used to inspect a wider range of products. They are also useful for quality control and failure analysis, as they can provide detailed reports on the types and locations of defects. Both Inline and Offline 3D AOI systems play a crucial role in ensuring the quality and reliability of electronic assemblies. The choice between the two depends on the specific needs and production requirements of the manufacturer. Inline systems are preferred for high-speed, high-volume production lines, while Offline systems are better suited for detailed inspections and quality control. As the demand for more complex and miniaturized electronic components continues to grow, the importance of both Inline and Offline 3D AOI systems in the manufacturing process will only increase.

PCB Industry, Panel Display Industry, Other Industries (Semiconductors, Solar Cells, Medical, etc.) in the Global 3D Automated Optical Inspection (AOI) Market:

The usage of Global 3D Automated Optical Inspection (AOI) Market spans across various industries, including the PCB Industry, Panel Display Industry, and other sectors such as Semiconductors, Solar Cells, and Medical devices. In the PCB Industry, 3D AOI systems are essential for ensuring the quality and reliability of printed circuit boards. These systems can detect a wide range of defects, including solder joint issues, component misalignment, and surface anomalies. By providing real-time feedback and detailed inspection reports, 3D AOI systems help manufacturers maintain high-quality standards and reduce the risk of defective products. In the Panel Display Industry, 3D AOI systems are used to inspect flat-panel displays, such as LCDs and OLEDs, for defects and inconsistencies. These systems can detect issues such as pixel defects, surface scratches, and alignment errors, ensuring that the displays meet the required quality standards. The high precision and accuracy of 3D AOI systems make them ideal for inspecting the intricate and delicate components of panel displays. In other industries, such as Semiconductors, Solar Cells, and Medical devices, 3D AOI systems play a crucial role in quality control and assurance. In the Semiconductor industry, these systems are used to inspect wafers and chips for defects, ensuring that they meet the stringent quality requirements. In the Solar Cell industry, 3D AOI systems are used to inspect solar panels for defects and inconsistencies, ensuring that they perform efficiently and reliably. In the Medical device industry, 3D AOI systems are used to inspect various medical devices and components, ensuring that they meet the required safety and quality standards. Overall, the usage of 3D AOI systems in these industries helps manufacturers maintain high-quality standards, reduce the risk of defective products, and improve overall production efficiency.

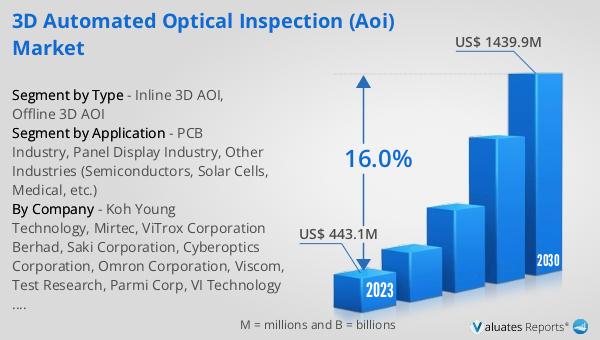

Global 3D Automated Optical Inspection (AOI) Market Outlook:

The global market for 3D Automated Optical Inspection (AOI) is anticipated to grow significantly, with projections indicating it will reach approximately US$ 1439.9 million by 2030, up from an estimated US$ 591 million in 2024, reflecting a compound annual growth rate (CAGR) of 16.0% during the period from 2024 to 2030. The top five players in the 3D AOI market collectively hold around 64% of the total global market share. The Asia Pacific region stands out as the largest consumer market for 3D AOI, accounting for about 69% of the global consumption, followed by North America and Europe. When it comes to the types of 3D AOI systems, Inline 3D AOI is the dominant segment, making up 87% of the market share. This significant market share highlights the preference for Inline systems in high-volume production environments where real-time inspection and immediate feedback are crucial. The robust growth in the 3D AOI market is driven by the increasing complexity of electronic devices, the demand for higher quality standards, and the need for faster production cycles. As electronic components become smaller and more densely packed, the precision and accuracy offered by 3D AOI systems become indispensable. Additionally, the integration of advanced technologies such as artificial intelligence and machine learning into AOI systems is enhancing their capabilities, making them more efficient and reliable. The market is also benefiting from the growing adoption of Industry 4.0 practices, which emphasize automation and data-driven decision-making in manufacturing processes. Overall, the global 3D AOI market is poised for significant growth as it continues to evolve and adapt to the changing needs of the electronics industry.

| Report Metric | Details |

| Report Name | 3D Automated Optical Inspection (AOI) Market |

| Accounted market size in 2024 | an estimated US$ 591 in million |

| Forecasted market size in 2030 | US$ 1439.9 million |

| CAGR | 16.0% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Koh Young Technology, Mirtec, ViTrox Corporation Berhad, Saki Corporation, Cyberoptics Corporation, Omron Corporation, Viscom, Test Research, Parmi Corp, VI Technology (Mycronic), GÖPEL electronic GmbH, Machine Vision Products (MVP), Mek Marantz Electronics, Pemtron Corp., Nordson YESTECH, JUTZE Intelligence Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |