What is Global Ultra-thin Copper Foil for IC Packaging Market?

The Global Ultra-thin Copper Foil for IC Packaging Market is a specialized segment within the broader electronics and semiconductor industry. Ultra-thin copper foil is a critical material used in the packaging of integrated circuits (ICs), which are essential components in a wide range of electronic devices. This type of copper foil is characterized by its extremely thin gauge, typically ranging from 2 micrometers (μm) to 5 micrometers (μm). The ultra-thin nature of this foil allows for the creation of smaller, more efficient, and higher-performing IC packages. These packages are crucial for the miniaturization of electronic devices, enabling advancements in technology such as smartphones, tablets, and other portable electronics. The demand for ultra-thin copper foil is driven by the need for high-density interconnects and the ongoing trend towards smaller and more powerful electronic devices. The market for this material is growing as manufacturers seek to improve the performance and efficiency of their products while reducing size and weight.

2μm, 3μm, 4μm, 5μm in the Global Ultra-thin Copper Foil for IC Packaging Market:

In the Global Ultra-thin Copper Foil for IC Packaging Market, the different thicknesses of copper foil, such as 2μm, 3μm, 4μm, and 5μm, play a significant role in determining the performance and application of the IC packages. The 2μm copper foil is the thinnest and is typically used in applications where space is at a premium and high-density interconnects are required. This ultra-thin foil allows for the creation of extremely compact IC packages, which are essential for modern electronic devices that demand high performance in a small form factor. The 3μm copper foil, while slightly thicker, still offers excellent performance and is often used in applications where a balance between size and performance is needed. This thickness is suitable for a wide range of IC packaging applications, providing good electrical conductivity and thermal performance. The 4μm copper foil is used in applications where additional mechanical strength is required without significantly compromising the compactness of the IC package. This thickness provides a good balance between durability and performance, making it suitable for a variety of electronic devices. Finally, the 5μm copper foil, being the thickest among the ultra-thin options, is used in applications where mechanical robustness is a priority. This thickness is ideal for IC packages that need to withstand higher levels of mechanical stress and thermal cycling. Each of these thicknesses offers unique advantages, and the choice of which to use depends on the specific requirements of the IC packaging application. The ongoing advancements in technology and the increasing demand for smaller, more powerful electronic devices continue to drive the development and use of ultra-thin copper foil in the IC packaging market.

BGA, CSP, Others in the Global Ultra-thin Copper Foil for IC Packaging Market:

The usage of Global Ultra-thin Copper Foil for IC Packaging Market extends to various areas, including Ball Grid Array (BGA), Chip Scale Package (CSP), and other packaging types. In BGA applications, ultra-thin copper foil is used to create a high-density interconnect system that allows for efficient electrical connections between the IC and the printed circuit board (PCB). The thinness of the copper foil enables the creation of smaller and more compact BGA packages, which are essential for modern electronic devices that require high performance in a limited space. The use of ultra-thin copper foil in BGA packages also helps to improve thermal management, as the copper provides excellent thermal conductivity, allowing for better heat dissipation. In CSP applications, ultra-thin copper foil is used to create extremely small and lightweight IC packages. CSPs are a type of surface-mount packaging that allows for direct mounting of the IC onto the PCB, reducing the overall size and weight of the electronic device. The use of ultra-thin copper foil in CSPs helps to improve electrical performance and reliability, as the thin copper layers provide excellent electrical conductivity and reduce the risk of signal loss. Additionally, the thinness of the copper foil allows for the creation of more complex and densely packed IC designs, enabling the development of advanced electronic devices with higher performance capabilities. In other packaging types, such as wafer-level packaging and flip-chip packaging, ultra-thin copper foil is used to create high-performance interconnects that improve the overall performance and reliability of the IC package. The use of ultra-thin copper foil in these applications helps to reduce the size and weight of the IC package, improve thermal management, and enhance electrical performance. Overall, the use of ultra-thin copper foil in various IC packaging applications is essential for the development of modern electronic devices that require high performance, reliability, and compactness.

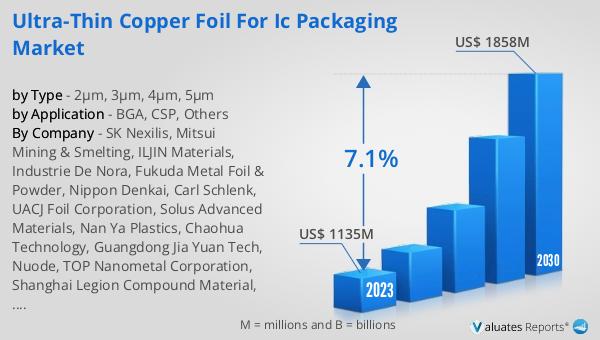

Global Ultra-thin Copper Foil for IC Packaging Market Outlook:

The global market for Ultra-thin Copper Foil used in IC Packaging was valued at approximately $1,135 million in 2023. Projections indicate that this market is expected to grow significantly, reaching an estimated value of $1,858 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 7.1% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for smaller, more efficient, and higher-performing electronic devices, which in turn drives the need for advanced IC packaging solutions. The ultra-thin copper foil market is benefiting from technological advancements and the ongoing miniaturization of electronic components. As manufacturers continue to innovate and develop new applications for ultra-thin copper foil, the market is poised for sustained growth. The projected growth rate underscores the importance of ultra-thin copper foil in the electronics and semiconductor industries, highlighting its critical role in enabling the development of next-generation electronic devices.

| Report Metric | Details |

| Report Name | Ultra-thin Copper Foil for IC Packaging Market |

| Accounted market size in 2023 | US$ 1135 million |

| Forecasted market size in 2030 | US$ 1858 million |

| CAGR | 7.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SK Nexilis, Mitsui Mining & Smelting, ILJIN Materials, Industrie De Nora, Fukuda Metal Foil & Powder, Nippon Denkai, Carl Schlenk, UACJ Foil Corporation, Solus Advanced Materials, Nan Ya Plastics, Chaohua Technology, Guangdong Jia Yuan Tech, Nuode, TOP Nanometal Corporation, Shanghai Legion Compound Material, Guangzhou Fangbang Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |