What is Global Robotic Case Packing System Market?

The Global Robotic Case Packing System Market refers to the industry focused on the development, production, and implementation of robotic systems designed to automate the process of packing products into cases. These systems are widely used in various industries to enhance efficiency, accuracy, and speed in packaging operations. The market encompasses a range of robotic technologies, including articulated robots, delta robots, and collaborative robots, each tailored to specific packaging needs. The adoption of robotic case packing systems is driven by the increasing demand for automation in manufacturing and packaging processes, aiming to reduce labor costs, minimize human error, and improve overall productivity. These systems are particularly beneficial in high-volume production environments where consistency and precision are crucial. The market is characterized by continuous advancements in robotics technology, integration of artificial intelligence, and the development of more flexible and adaptable systems to meet the diverse requirements of different industries. As businesses strive to optimize their operations and meet the growing consumer demand for packaged goods, the Global Robotic Case Packing System Market is expected to witness significant growth in the coming years.

Side Load, Top Load in the Global Robotic Case Packing System Market:

Side Load and Top Load are two primary configurations in the Global Robotic Case Packing System Market, each offering distinct advantages based on the specific needs of the packaging process. Side Load systems are designed to load products into cases from the side, making them ideal for packaging items that are stable and can be easily oriented horizontally. These systems are particularly useful for products like bottles, cans, and cartons, where maintaining the product's orientation during the packing process is crucial. Side Load systems are known for their high speed and efficiency, making them suitable for high-volume production lines. They are also relatively easy to integrate into existing production lines, offering flexibility and scalability for manufacturers. On the other hand, Top Load systems load products into cases from the top, which is advantageous for products that are more stable when oriented vertically. This configuration is often used for packaging items such as jars, tubs, and other containers that need to remain upright during the packing process. Top Load systems are known for their precision and ability to handle a wide variety of product shapes and sizes. They are particularly beneficial in industries where product stability and orientation are critical, such as the food and beverage industry. Additionally, Top Load systems can be designed to handle delicate products with care, reducing the risk of damage during the packing process. Both Side Load and Top Load systems can be equipped with advanced robotic technologies, including vision systems and sensors, to enhance their performance and adaptability. Vision systems enable the robots to identify and orient products accurately, ensuring precise placement into cases. Sensors can detect any anomalies in the packing process, allowing for real-time adjustments and minimizing the risk of errors. These technologies contribute to the overall efficiency and reliability of robotic case packing systems, making them an essential component of modern packaging operations. The choice between Side Load and Top Load systems depends on various factors, including the type of product being packaged, the required speed and efficiency, and the specific needs of the production line. Manufacturers often conduct thorough evaluations to determine the most suitable configuration for their operations. In some cases, a combination of both Side Load and Top Load systems may be used to achieve optimal results. The flexibility and adaptability of robotic case packing systems make them a valuable investment for businesses looking to enhance their packaging processes and meet the demands of a competitive market. In conclusion, Side Load and Top Load systems represent two key configurations in the Global Robotic Case Packing System Market, each offering unique benefits based on the specific requirements of the packaging process. Side Load systems are ideal for high-speed, high-volume production lines, while Top Load systems provide precision and stability for a wide range of products. The integration of advanced robotic technologies further enhances the performance and reliability of these systems, making them indispensable in modern packaging operations. As the demand for automation continues to grow, the Global Robotic Case Packing System Market is poised for significant advancements and expansion.

Food, Drug, Cosmetic, Chemical, Others in the Global Robotic Case Packing System Market:

The usage of Global Robotic Case Packing System Market spans across various industries, including Food, Drug, Cosmetic, Chemical, and others, each benefiting from the enhanced efficiency and precision offered by robotic systems. In the Food industry, robotic case packing systems are widely used to handle a diverse range of products, from packaged snacks and beverages to frozen foods and dairy products. These systems ensure that products are packed consistently and securely, reducing the risk of damage and contamination. The ability to handle high volumes of products with speed and accuracy makes robotic case packing systems an invaluable asset in the food industry, where maintaining product quality and meeting stringent safety standards are paramount. In the Drug industry, robotic case packing systems play a crucial role in ensuring the safe and efficient packaging of pharmaceuticals. These systems are designed to handle delicate and sensitive products, such as vials, syringes, and blister packs, with precision and care. The integration of vision systems and sensors allows for accurate identification and orientation of products, minimizing the risk of errors and ensuring compliance with regulatory requirements. The use of robotic case packing systems in the drug industry not only enhances productivity but also ensures the integrity and safety of pharmaceutical products throughout the packaging process. The Cosmetic industry also benefits significantly from the adoption of robotic case packing systems. These systems are used to pack a wide variety of cosmetic products, including bottles, jars, tubes, and compacts, with precision and consistency. The ability to handle different shapes and sizes of products makes robotic case packing systems ideal for the cosmetic industry, where packaging aesthetics and product presentation are critical. Additionally, the use of robotic systems reduces the risk of contamination and damage, ensuring that cosmetic products reach consumers in perfect condition. In the Chemical industry, robotic case packing systems are used to handle a range of products, from hazardous chemicals to household cleaning products. These systems are designed to operate in challenging environments, where safety and precision are paramount. The use of robotic systems in the chemical industry enhances efficiency and reduces the risk of human exposure to hazardous substances. Advanced technologies, such as vision systems and sensors, enable robots to handle products with care and accuracy, ensuring that they are packed securely and safely. Other industries, such as electronics, automotive, and consumer goods, also benefit from the use of robotic case packing systems. In the electronics industry, these systems are used to pack delicate and sensitive components, such as circuit boards and semiconductors, with precision and care. In the automotive industry, robotic case packing systems are used to handle a variety of parts and components, ensuring that they are packed securely and efficiently. In the consumer goods industry, these systems are used to pack a wide range of products, from household items to personal care products, with speed and accuracy. In summary, the usage of Global Robotic Case Packing System Market extends across multiple industries, each benefiting from the enhanced efficiency, precision, and reliability offered by robotic systems. In the Food industry, these systems ensure consistent and secure packaging of products, while in the Drug industry, they enhance the safety and integrity of pharmaceuticals. The Cosmetic industry benefits from the precision and consistency of robotic systems, while the Chemical industry relies on them for safe and efficient handling of hazardous substances. Other industries, such as electronics, automotive, and consumer goods, also leverage the advantages of robotic case packing systems to enhance their packaging processes and meet the demands of a competitive market.

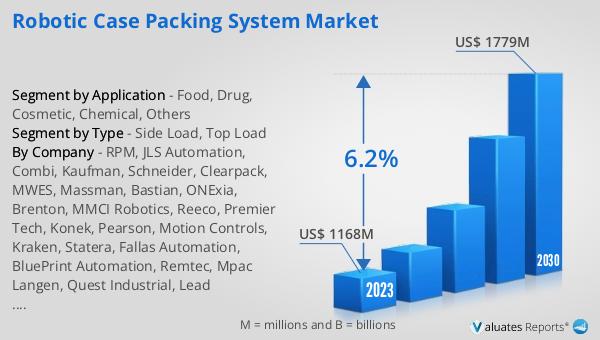

Global Robotic Case Packing System Market Outlook:

The global Robotic Case Packing System market was valued at US$ 1168 million in 2023 and is anticipated to reach US$ 1779 million by 2030, witnessing a CAGR of 6.2% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the robotic case packing system industry over the next several years. The valuation of US$ 1168 million in 2023 underscores the current scale and importance of this market in the global economy. The projected increase to US$ 1779 million by 2030 indicates a robust demand for advanced packaging solutions driven by the need for automation, efficiency, and precision in various industries. The compound annual growth rate (CAGR) of 6.2% reflects a steady and sustained expansion, suggesting that businesses are increasingly recognizing the benefits of robotic case packing systems in enhancing their operational capabilities. This growth trajectory is likely fueled by continuous technological advancements, the integration of artificial intelligence, and the development of more flexible and adaptable robotic systems. As industries such as food, pharmaceuticals, cosmetics, chemicals, and consumer goods continue to seek innovative solutions to optimize their packaging processes, the global Robotic Case Packing System market is poised to play a crucial role in meeting these evolving demands.

| Report Metric | Details |

| Report Name | Robotic Case Packing System Market |

| Accounted market size in 2023 | US$ 1168 million |

| Forecasted market size in 2030 | US$ 1779 million |

| CAGR | 6.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | RPM, JLS Automation, Combi, Kaufman, Schneider, Clearpack, MWES, Massman, Bastian, ONExia, Brenton, MMCI Robotics, Reeco, Premier Tech, Konek, Pearson, Motion Controls, Kraken, Statera, Fallas Automation, BluePrint Automation, Remtec, Mpac Langen, Quest Industrial, Lead Technology, Zenon Automation, ESS Technologies, PWR Pack, Qcomp, Remtech Systems, Douglas, Descon, ADCO Manufacturing, ROBOVIC, Allied Technology, Rothe Packtech, Promation, Opus Automation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |