What is Global Protable Industrial Videoscope Market?

The Global Portable Industrial Videoscope Market is a specialized segment within the broader industrial inspection and maintenance industry. Portable industrial videoscopes are advanced, handheld devices equipped with a flexible insertion tube and a camera at the tip, allowing operators to visually inspect areas that are otherwise inaccessible. These devices are crucial for non-destructive testing (NDT) and are widely used in various industries such as aerospace, automotive, manufacturing, and chemical processing. The primary function of these videoscopes is to provide real-time visual feedback, enabling technicians to identify defects, corrosion, blockages, or other issues within machinery and infrastructure. The market for portable industrial videoscopes is driven by the increasing need for regular maintenance and inspection to ensure operational efficiency and safety. With advancements in technology, these devices have become more sophisticated, offering features like high-resolution imaging, digital storage, and remote connectivity. The global market for portable industrial videoscopes is expected to grow steadily, driven by the rising demand for efficient and reliable inspection tools across various industrial sectors.

2-way rotation, 4-way rotation, Other in the Global Protable Industrial Videoscope Market:

In the Global Portable Industrial Videoscope Market, the devices are often categorized based on their articulation capabilities, which include 2-way rotation, 4-way rotation, and other types. The 2-way rotation videoscopes allow the camera tip to move in two directions, typically up and down. This type of articulation is suitable for straightforward inspections where the area of interest is relatively accessible. It provides a basic level of maneuverability, making it ideal for routine inspections in less complex environments. On the other hand, 4-way rotation videoscopes offer a higher degree of flexibility, with the camera tip capable of moving in four directions: up, down, left, and right. This enhanced maneuverability is crucial for inspecting more complex and confined spaces, such as intricate machinery or internal components of an aircraft engine. The ability to navigate through tight and winding paths allows for a more comprehensive inspection, ensuring that no area is left unchecked. Additionally, there are videoscopes with even more advanced articulation capabilities, often referred to as "other" types. These may include devices with joystick control for precise movement, 360-degree rotation, or even robotic articulation for automated inspections. These advanced features are particularly useful in highly specialized applications where precision and thoroughness are paramount. For instance, in the aerospace industry, the ability to inspect every nook and cranny of an aircraft's internal structure is critical for safety and compliance with regulatory standards. Similarly, in the chemical industry, where pipelines and reactors need regular inspection, advanced articulation can help identify potential issues before they escalate into major problems. The choice of articulation type depends largely on the specific requirements of the inspection task at hand. While 2-way rotation may suffice for simpler applications, 4-way and other advanced types offer the versatility and precision needed for more demanding inspections. As technology continues to evolve, we can expect to see further innovations in the articulation capabilities of portable industrial videoscopes, enhancing their utility and effectiveness across various industries.

Machinery Manufacturing, Auto Repair, Aerospace, Chemical, Railroad Construction, Others in the Global Protable Industrial Videoscope Market:

The Global Portable Industrial Videoscope Market finds extensive usage across several key industries, including machinery manufacturing, auto repair, aerospace, chemical, railroad construction, and others. In machinery manufacturing, these devices are indispensable for inspecting the internal components of machines and equipment. They help in identifying wear and tear, misalignments, and other defects that could affect the performance and longevity of the machinery. Regular inspections using videoscopes ensure that any issues are detected early, allowing for timely maintenance and reducing the risk of costly breakdowns. In the auto repair industry, portable industrial videoscopes are used to inspect the internal parts of vehicles, such as engines, exhaust systems, and transmissions. They enable mechanics to diagnose problems without the need for disassembly, saving time and labor costs. This non-invasive inspection method is particularly valuable for modern vehicles, which often have complex and tightly packed components. In the aerospace industry, the use of portable industrial videoscopes is critical for maintaining the safety and reliability of aircraft. These devices are used to inspect the internal structures of aircraft engines, fuselages, and other components. They help in detecting cracks, corrosion, and other defects that could compromise the integrity of the aircraft. Regular inspections using videoscopes are essential for compliance with stringent safety regulations and for ensuring the airworthiness of aircraft. In the chemical industry, portable industrial videoscopes are used to inspect pipelines, reactors, and other equipment. They help in identifying blockages, corrosion, and other issues that could affect the efficiency and safety of chemical processes. Regular inspections using videoscopes ensure that any potential problems are detected early, allowing for timely maintenance and reducing the risk of accidents. In railroad construction, portable industrial videoscopes are used to inspect the internal components of trains and tracks. They help in identifying wear and tear, misalignments, and other defects that could affect the performance and safety of the railway system. Regular inspections using videoscopes ensure that any issues are detected early, allowing for timely maintenance and reducing the risk of accidents. Other industries that use portable industrial videoscopes include power generation, oil and gas, and food processing. In each of these industries, the ability to conduct non-destructive inspections using videoscopes is invaluable for maintaining the efficiency, safety, and reliability of equipment and processes.

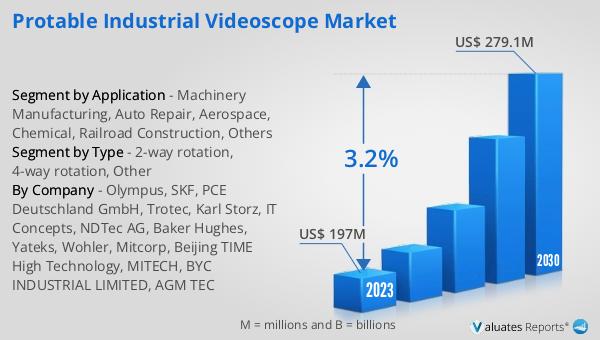

Global Protable Industrial Videoscope Market Outlook:

The global Portable Industrial Videoscope market was valued at US$ 197 million in 2023 and is anticipated to reach US$ 279.1 million by 2030, witnessing a CAGR of 3.2% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for advanced inspection tools across various industries. Portable industrial videoscopes have become essential for non-destructive testing and maintenance, offering high-resolution imaging and real-time visual feedback. The market's expansion is driven by the need for regular maintenance and inspection to ensure operational efficiency and safety. As industries continue to prioritize reliability and safety, the demand for portable industrial videoscopes is expected to rise steadily. The advancements in technology, such as digital storage and remote connectivity, further enhance the utility and effectiveness of these devices, making them indispensable tools for technicians and engineers. The market's growth trajectory indicates a robust future for portable industrial videoscopes, with increasing applications across diverse industrial sectors.

| Report Metric | Details |

| Report Name | Protable Industrial Videoscope Market |

| Accounted market size in 2023 | US$ 197 million |

| Forecasted market size in 2030 | US$ 279.1 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Olympus, SKF, PCE Deutschland GmbH, Trotec, Karl Storz, IT Concepts, NDTec AG, Baker Hughes, Yateks, Wohler, Mitcorp, Beijing TIME High Technology, MITECH, BYC INDUSTRIAL LIMITED, AGM TEC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |