What is Global Magnetic Thickness Gauges Market?

The Global Magnetic Thickness Gauges Market refers to the worldwide industry focused on the production, distribution, and utilization of magnetic thickness gauges. These devices are essential tools used to measure the thickness of non-magnetic coatings on magnetic substrates. They are widely employed in various industries to ensure quality control, maintain standards, and enhance product reliability. The market encompasses a range of products, including portable and stationary gauges, each designed to meet specific needs and applications. The demand for these gauges is driven by their accuracy, ease of use, and the growing emphasis on quality assurance across different sectors. As industries continue to evolve and prioritize precision, the global market for magnetic thickness gauges is expected to expand, offering innovative solutions to meet the diverse requirements of its users.

Portable, Stationary in the Global Magnetic Thickness Gauges Market:

Portable and stationary magnetic thickness gauges are two primary types of devices used in the Global Magnetic Thickness Gauges Market. Portable magnetic thickness gauges are compact, lightweight, and designed for on-the-go measurements. They are ideal for fieldwork, allowing technicians to quickly and accurately measure coating thickness in various locations. These portable devices are equipped with user-friendly interfaces, making them accessible to both experienced professionals and novices. They are commonly used in industries such as automotive, aerospace, and construction, where mobility and flexibility are crucial. On the other hand, stationary magnetic thickness gauges are designed for fixed installations in laboratories or production lines. These gauges offer higher precision and are often integrated into automated systems for continuous monitoring and quality control. Stationary gauges are essential in industries where consistent and accurate measurements are critical, such as in manufacturing and metallurgical processes. Both types of gauges utilize magnetic principles to measure the thickness of non-magnetic coatings on magnetic substrates. The choice between portable and stationary gauges depends on the specific needs of the application, including factors such as the required level of precision, the environment in which the measurements will be taken, and the frequency of use. As technology advances, both portable and stationary magnetic thickness gauges are becoming more sophisticated, offering enhanced features such as digital displays, data storage, and connectivity options. These advancements are making it easier for industries to maintain high standards of quality and efficiency. The global market for magnetic thickness gauges continues to grow, driven by the increasing demand for accurate and reliable measurement tools across various sectors. Whether for field inspections or in-line quality control, magnetic thickness gauges play a vital role in ensuring the integrity and performance of coated materials.

Metallurgical, Automobile, Chemical, Other in the Global Magnetic Thickness Gauges Market:

Magnetic thickness gauges are extensively used in various industries, including metallurgical, automobile, chemical, and others, to ensure the quality and reliability of products. In the metallurgical industry, these gauges are crucial for measuring the thickness of protective coatings on metal surfaces. This helps in preventing corrosion and ensuring the longevity of metal components. Accurate thickness measurements are essential for maintaining the structural integrity of metal products, which is vital in applications such as construction, shipbuilding, and heavy machinery. In the automobile industry, magnetic thickness gauges are used to measure the thickness of paint and other coatings on vehicles. This ensures a uniform finish and helps in maintaining the aesthetic appeal of the vehicles. Additionally, accurate coating measurements are important for protecting the underlying metal from corrosion and wear, thereby enhancing the durability and lifespan of the vehicles. In the chemical industry, magnetic thickness gauges are used to measure the thickness of coatings on storage tanks, pipelines, and other equipment. This is crucial for preventing chemical reactions between the stored substances and the metal surfaces, which can lead to contamination and equipment failure. Accurate thickness measurements help in maintaining the safety and efficiency of chemical processes. Other industries, such as aerospace, electronics, and consumer goods, also rely on magnetic thickness gauges for quality control and assurance. In the aerospace industry, these gauges are used to measure the thickness of coatings on aircraft components, ensuring their performance and safety. In the electronics industry, magnetic thickness gauges are used to measure the thickness of coatings on circuit boards and other electronic components, ensuring their reliability and functionality. In the consumer goods industry, these gauges are used to measure the thickness of coatings on various products, ensuring their quality and durability. Overall, the use of magnetic thickness gauges in these industries helps in maintaining high standards of quality, safety, and efficiency.

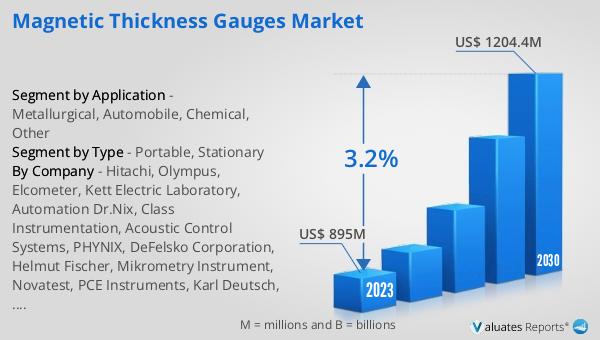

Global Magnetic Thickness Gauges Market Outlook:

The global Magnetic Thickness Gauges market was valued at US$ 895 million in 2023 and is anticipated to reach US$ 1204.4 million by 2030, witnessing a CAGR of 3.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for accurate and reliable measurement tools across various sectors. The growth is attributed to the rising emphasis on quality control and assurance in industries such as automotive, aerospace, construction, and manufacturing. As these industries continue to evolve and prioritize precision, the demand for magnetic thickness gauges is expected to rise. The market is also benefiting from technological advancements that are making these devices more sophisticated and user-friendly. Features such as digital displays, data storage, and connectivity options are enhancing the functionality and efficiency of magnetic thickness gauges, making them indispensable tools for quality control. The steady growth of the market reflects the critical role that magnetic thickness gauges play in ensuring the integrity and performance of coated materials. As industries continue to prioritize quality and efficiency, the global market for magnetic thickness gauges is poised for sustained growth.

| Report Metric | Details |

| Report Name | Magnetic Thickness Gauges Market |

| Accounted market size in 2023 | US$ 895 million |

| Forecasted market size in 2030 | US$ 1204.4 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hitachi, Olympus, Elcometer, Kett Electric Laboratory, Automation Dr.Nix, Class Instrumentation, Acoustic Control Systems, PHYNIX, DeFelsko Corporation, Helmut Fischer, Mikrometry Instrument, Novatest, PCE Instruments, Karl Deutsch, Beijing TIME High Technology, Beijing Cap High Technology, Leader Precision Instrument, MITECH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |