What is Global Pressure Vessel Sight Glass Market?

The Global Pressure Vessel Sight Glass Market refers to the industry that manufactures and supplies sight glasses specifically designed for pressure vessels. These sight glasses are essential components used in various industries to allow operators to visually inspect the contents and processes within a pressure vessel without opening it. This market encompasses a wide range of products, including different types of glass materials and configurations, to meet the diverse needs of industries such as chemical, petroleum, pharmaceutical, and others. The demand for pressure vessel sight glasses is driven by the need for safety, efficiency, and reliability in industrial processes. These sight glasses must withstand high pressure, temperature, and corrosive environments, making their quality and durability crucial. The market is influenced by factors such as technological advancements, regulatory standards, and the growth of end-use industries. As industries continue to prioritize safety and operational efficiency, the Global Pressure Vessel Sight Glass Market is expected to see sustained demand and innovation.

Tempered Glass, Tempered Borosilicate Glass, Quartz Glass, Other in the Global Pressure Vessel Sight Glass Market:

Tempered glass, tempered borosilicate glass, quartz glass, and other materials play a significant role in the Global Pressure Vessel Sight Glass Market. Tempered glass is known for its strength and safety features. It is produced by heating the glass to a high temperature and then rapidly cooling it, which makes it much stronger than regular glass. This type of glass is widely used in pressure vessel sight glasses because it can withstand high pressure and temperature variations. Tempered borosilicate glass, on the other hand, is a type of glass that contains boron trioxide, which allows it to have very low thermal expansion. This makes it resistant to thermal shock, meaning it can withstand sudden changes in temperature without cracking. This property is particularly useful in industries where processes involve rapid temperature changes. Quartz glass is another material used in pressure vessel sight glasses. It is made from high-purity silica and is known for its exceptional thermal and chemical resistance. Quartz glass can withstand extremely high temperatures and is resistant to most chemicals, making it ideal for use in harsh industrial environments. Other materials used in the production of pressure vessel sight glasses include various types of specialty glasses and composites that offer unique properties such as enhanced durability, chemical resistance, or optical clarity. Each of these materials has its own set of advantages and is chosen based on the specific requirements of the application. For instance, in the chemical industry, where corrosive substances are common, materials with high chemical resistance like quartz glass or borosilicate glass are preferred. In the pharmaceutical industry, where purity and clarity are crucial, materials that offer high optical clarity and resistance to contamination are chosen. The choice of material also depends on factors such as cost, availability, and the specific standards and regulations of the industry. Overall, the variety of materials available for pressure vessel sight glasses allows manufacturers to provide solutions that meet the diverse needs of different industries, ensuring safety, efficiency, and reliability in their operations.

Chemical Industry, Petroleum, Pharmaceutical, Other in the Global Pressure Vessel Sight Glass Market:

The Global Pressure Vessel Sight Glass Market finds extensive usage in various industries, including the chemical industry, petroleum, pharmaceutical, and others. In the chemical industry, pressure vessel sight glasses are crucial for monitoring chemical reactions and processes. They allow operators to visually inspect the contents of a vessel, ensuring that reactions are proceeding as expected and that there are no issues such as blockages or leaks. This is particularly important in processes that involve hazardous or corrosive chemicals, where safety is a top priority. In the petroleum industry, pressure vessel sight glasses are used in various applications, including refining, petrochemical processing, and storage. They enable operators to monitor the flow and condition of petroleum products, ensuring that processes are running smoothly and efficiently. The ability to visually inspect the contents of a vessel without opening it is essential in this industry, where high pressure and flammable substances are common. In the pharmaceutical industry, pressure vessel sight glasses are used in the production of drugs and other medical products. They allow operators to monitor the production process, ensuring that it meets strict quality and safety standards. The use of sight glasses in this industry is critical for maintaining the purity and integrity of pharmaceutical products, as any contamination or deviation from the process can have serious consequences. Other industries that use pressure vessel sight glasses include food and beverage, water treatment, and power generation. In the food and beverage industry, sight glasses are used to monitor the production and processing of food products, ensuring that they meet quality and safety standards. In water treatment, sight glasses are used to monitor the treatment process, ensuring that water is being properly purified and treated. In power generation, sight glasses are used to monitor the flow and condition of fluids in various systems, ensuring that they are operating efficiently and safely. Overall, the use of pressure vessel sight glasses in these industries is essential for ensuring the safety, efficiency, and reliability of industrial processes. They provide a critical means of monitoring and inspecting the contents of a vessel, allowing operators to quickly identify and address any issues that may arise.

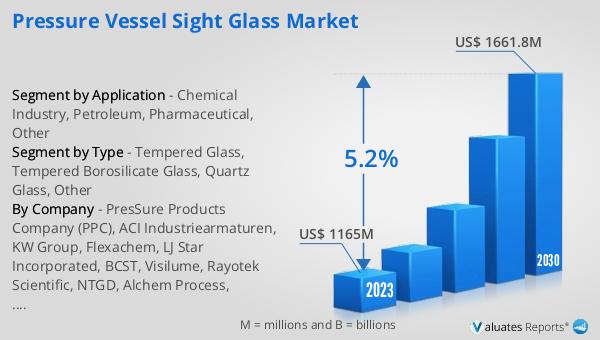

Global Pressure Vessel Sight Glass Market Outlook:

The global Pressure Vessel Sight Glass market was valued at US$ 1165 million in 2023 and is anticipated to reach US$ 1661.8 million by 2030, witnessing a CAGR of 5.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for safety and efficiency in industrial processes. The growth is attributed to the rising adoption of pressure vessel sight glasses across various industries, including chemical, petroleum, pharmaceutical, and others. As industries continue to prioritize operational safety and efficiency, the demand for high-quality sight glasses that can withstand harsh conditions is expected to rise. The market is also influenced by technological advancements and regulatory standards that require the use of reliable and durable sight glasses in pressure vessels. The projected growth in the market value reflects the ongoing investments in industrial infrastructure and the need for advanced monitoring solutions. Overall, the Global Pressure Vessel Sight Glass Market is poised for significant growth, driven by the increasing emphasis on safety, efficiency, and technological innovation in industrial processes.

| Report Metric | Details |

| Report Name | Pressure Vessel Sight Glass Market |

| Accounted market size in 2023 | US$ 1165 million |

| Forecasted market size in 2030 | US$ 1661.8 million |

| CAGR | 5.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PresSure Products Company (PPC), ACI Industriearmaturen, KW Group, Flexachem, LJ Star Incorporated, BCST, Visilume, Rayotek Scientific, NTGD, Alchem Process, Wenzhou Kosun Fluid Equipment, Iniflu, Quzhou KingGo Machinery, Chemical Support Systems, Uni Klinger, Sightflow, CMC Technologies, Corrosion Resistant Products, Teleflo Instruments And Controls, Level and Flow Control Engineers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |