What is Global Polyphenylene Oxide (PPO) Plastic Market?

The Global Polyphenylene Oxide (PPO) Plastic Market is a significant segment within the broader plastics industry, known for its unique properties and diverse applications. Polyphenylene Oxide (PPO) is a high-performance engineering thermoplastic that exhibits excellent thermal stability, mechanical strength, and electrical insulating properties. These characteristics make it highly desirable in various industries, including automotive, electronics, and appliances. The market for PPO plastics is driven by the increasing demand for lightweight, durable, and heat-resistant materials that can replace traditional metals and other plastics. The versatility of PPO allows it to be used in a wide range of applications, from automotive components to electronic housings, making it a critical material in modern manufacturing. As industries continue to innovate and seek materials that offer better performance and sustainability, the demand for PPO plastics is expected to grow, further solidifying its position in the global market.

Powder, Granules in the Global Polyphenylene Oxide (PPO) Plastic Market:

Polyphenylene Oxide (PPO) plastics are available in various forms, including powder and granules, each offering distinct advantages depending on the application. PPO powder is typically used in processes that require precise control over particle size and distribution, such as injection molding and extrusion. The fine particles of PPO powder allow for uniform melting and mixing, resulting in high-quality finished products with consistent properties. This form is particularly useful in applications where intricate designs and detailed features are required, such as in electronic components and medical devices. On the other hand, PPO granules are preferred for applications that demand high throughput and efficiency. Granules are easier to handle and feed into processing equipment, making them ideal for large-scale manufacturing processes. They are commonly used in the production of automotive parts, where the material's high strength and heat resistance are crucial. The choice between powder and granules often depends on the specific requirements of the manufacturing process and the desired properties of the final product. Both forms of PPO offer excellent chemical resistance, low moisture absorption, and dimensional stability, making them suitable for a wide range of applications. Additionally, PPO can be blended with other polymers to enhance its properties and expand its range of uses. For example, blending PPO with polystyrene (PS) can improve its processability and impact resistance, making it suitable for applications that require a balance of strength and flexibility. The ability to modify PPO through blending and compounding further increases its versatility and appeal in various industries. As the demand for high-performance materials continues to rise, the availability of PPO in different forms ensures that manufacturers can choose the most suitable option for their specific needs, driving innovation and efficiency in the production of advanced products.

Automobile, Electronics, Appliances, Other in the Global Polyphenylene Oxide (PPO) Plastic Market:

The usage of Global Polyphenylene Oxide (PPO) Plastic Market spans several key industries, including automobiles, electronics, appliances, and others. In the automotive industry, PPO plastics are highly valued for their lightweight and durable properties, which contribute to improved fuel efficiency and reduced emissions. They are commonly used in the production of various components such as instrument panels, air intake manifolds, and exterior parts. The material's high heat resistance and mechanical strength make it ideal for under-the-hood applications where exposure to high temperatures and harsh conditions is common. In the electronics industry, PPO plastics are used in the manufacturing of connectors, housings, and other components that require excellent electrical insulating properties. The material's low moisture absorption and dimensional stability ensure reliable performance in electronic devices, even in challenging environments. PPO's flame retardant properties also make it a preferred choice for applications that require high safety standards. In the appliances sector, PPO plastics are used in the production of various household items such as washing machine parts, dishwasher components, and microwave oven parts. The material's resistance to heat and chemicals ensures long-lasting performance and durability in everyday use. Additionally, PPO's ability to be easily molded into complex shapes allows for innovative designs and improved functionality in household appliances. Beyond these primary industries, PPO plastics find applications in other areas such as medical devices, industrial equipment, and consumer goods. In the medical field, PPO's biocompatibility and sterilization resistance make it suitable for use in surgical instruments, diagnostic equipment, and other healthcare products. In industrial settings, PPO's mechanical strength and chemical resistance are leveraged in the production of various machinery components and protective gear. The versatility and high-performance characteristics of PPO plastics make them an essential material in modern manufacturing, driving advancements and efficiency across multiple sectors.

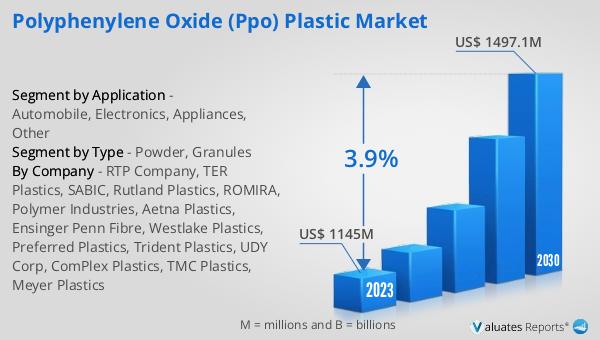

Global Polyphenylene Oxide (PPO) Plastic Market Outlook:

The market outlook for the Global Polyphenylene Oxide (PPO) Plastic Market indicates a promising growth trajectory. In 2023, the market was valued at approximately US$ 1145 million. Projections suggest that by 2030, this value is expected to rise to around US$ 1497.1 million. This anticipated growth reflects a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. This steady increase underscores the growing demand for PPO plastics across various industries, driven by their unique properties and versatile applications. The market's expansion is likely to be fueled by ongoing innovations and the continuous search for materials that offer better performance, sustainability, and efficiency. As industries such as automotive, electronics, and appliances continue to evolve and seek advanced materials, the role of PPO plastics in meeting these demands becomes increasingly significant. The projected growth in the market value highlights the importance of PPO plastics in modern manufacturing and their potential to drive future advancements in various sectors.

| Report Metric | Details |

| Report Name | Polyphenylene Oxide (PPO) Plastic Market |

| Accounted market size in 2023 | US$ 1145 million |

| Forecasted market size in 2030 | US$ 1497.1 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | RTP Company, TER Plastics, SABIC, Rutland Plastics, ROMIRA, Polymer Industries, Aetna Plastics, Ensinger Penn Fibre, Westlake Plastics, Preferred Plastics, Trident Plastics, UDY Corp, ComPlex Plastics, TMC Plastics, Meyer Plastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |