What is Global Photoelectric Deviation Correction Controller Market?

The Global Photoelectric Deviation Correction Controller Market is a specialized segment within the broader field of industrial automation and control systems. These controllers are designed to detect and correct deviations in the position of materials during various manufacturing processes. Utilizing photoelectric sensors, these devices ensure that materials such as paper, film, or textiles are aligned correctly as they move through production lines. This alignment is crucial for maintaining the quality and consistency of the final product. The market for these controllers is driven by the increasing demand for precision and efficiency in manufacturing processes across various industries, including printing, packaging, and textiles. As industries continue to automate and seek higher levels of accuracy, the demand for photoelectric deviation correction controllers is expected to grow. These controllers not only improve product quality but also reduce waste and operational costs, making them a valuable investment for manufacturers.

Edge Position Control, Line Position Control Type, Centerline Position Control Type in the Global Photoelectric Deviation Correction Controller Market:

Edge Position Control, Line Position Control Type, and Centerline Position Control Type are three primary methods used in the Global Photoelectric Deviation Correction Controller Market to ensure material alignment during manufacturing processes. Edge Position Control focuses on maintaining the position of the material's edge relative to a reference point. This method is particularly useful in industries where the material's edge must be precisely aligned, such as in the production of films, foils, and textiles. The photoelectric sensors detect any deviation from the desired edge position and send signals to the controller, which then adjusts the material's position accordingly. Line Position Control Type, on the other hand, is used to maintain the alignment of a specific line or pattern on the material. This method is commonly used in the printing industry, where the alignment of printed lines or patterns is crucial for the final product's quality. The photoelectric sensors detect any misalignment of the printed lines and send signals to the controller to correct the position. Centerline Position Control Type is used to maintain the material's centerline alignment relative to a reference point. This method is often used in the packaging industry, where the material's centerline must be precisely aligned to ensure proper packaging. The photoelectric sensors detect any deviation from the desired centerline position and send signals to the controller to adjust the material's position. Each of these control types plays a crucial role in ensuring the quality and consistency of the final product. By maintaining precise alignment, these controllers help reduce waste, improve efficiency, and enhance product quality. As industries continue to seek higher levels of automation and precision, the demand for these control types is expected to grow.

Printing Industry, Packaging Industry, Others in the Global Photoelectric Deviation Correction Controller Market:

The Global Photoelectric Deviation Correction Controller Market finds extensive usage in various industries, including the printing industry, packaging industry, and others. In the printing industry, these controllers are essential for maintaining the alignment of printed materials. Any deviation in the alignment can result in poor print quality, leading to waste and increased production costs. By using photoelectric deviation correction controllers, printers can ensure that the printed lines and patterns are precisely aligned, resulting in high-quality prints and reduced waste. In the packaging industry, these controllers are used to maintain the alignment of packaging materials. Proper alignment is crucial for ensuring that the packaging is done correctly and efficiently. Any deviation in the alignment can result in improper packaging, leading to product damage and increased production costs. By using photoelectric deviation correction controllers, packaging companies can ensure that the packaging materials are precisely aligned, resulting in efficient and high-quality packaging. In other industries, such as textiles and films, these controllers are used to maintain the alignment of materials during production. Proper alignment is crucial for ensuring the quality and consistency of the final product. Any deviation in the alignment can result in defects and increased production costs. By using photoelectric deviation correction controllers, manufacturers can ensure that the materials are precisely aligned, resulting in high-quality products and reduced waste. Overall, the usage of photoelectric deviation correction controllers in various industries helps improve product quality, reduce waste, and enhance production efficiency. As industries continue to seek higher levels of automation and precision, the demand for these controllers is expected to grow.

Global Photoelectric Deviation Correction Controller Market Outlook:

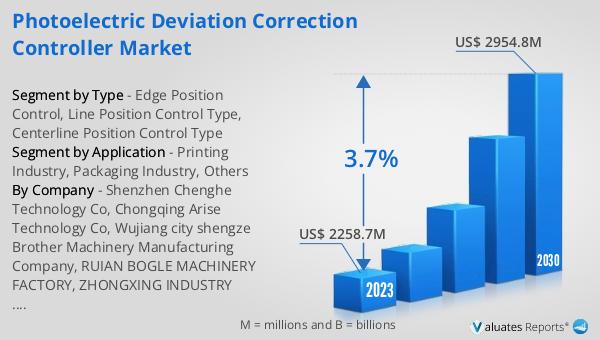

The global Photoelectric Deviation Correction Controller market was valued at US$ 2258.7 million in 2023 and is anticipated to reach US$ 2954.8 million by 2030, witnessing a CAGR of 3.7% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for precision and efficiency in manufacturing processes. The growth is attributed to the rising adoption of automation and control systems across various industries, including printing, packaging, and textiles. As manufacturers continue to seek higher levels of accuracy and efficiency, the demand for photoelectric deviation correction controllers is expected to rise. These controllers play a crucial role in ensuring the quality and consistency of the final product by maintaining precise alignment of materials during production. By reducing waste and operational costs, these controllers offer significant benefits to manufacturers, making them a valuable investment. The steady growth of the market reflects the increasing importance of precision and efficiency in modern manufacturing processes.

| Report Metric | Details |

| Report Name | Photoelectric Deviation Correction Controller Market |

| Accounted market size in 2023 | US$ 2258.7 million |

| Forecasted market size in 2030 | US$ 2954.8 million |

| CAGR | 3.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shenzhen Chenghe Technology Co, Chongqing Arise Technology Co, Wujiang city shengze Brother Machinery Manufacturing Company, RUIAN BOGLE MACHINERY FACTORY, ZHONGXING INDUSTRY CONTROL EQUIPMENT CO.,LTD, Huizhou Aibo Intelligent Control Equipment Co Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |