What is Global Pharmaceutical Metal Detector Market?

The Global Pharmaceutical Metal Detector Market is a specialized segment within the broader pharmaceutical industry that focuses on the development, production, and application of metal detection technologies to ensure the safety and quality of pharmaceutical products. These metal detectors are crucial in identifying and eliminating any metal contaminants that may be present in pharmaceutical products during the manufacturing process. Metal contamination can occur from various sources, such as machinery wear and tear, raw materials, or even human error. The presence of metal contaminants can compromise the safety, efficacy, and quality of pharmaceutical products, posing significant risks to patient health. Therefore, the implementation of metal detectors in pharmaceutical manufacturing is essential to comply with stringent regulatory standards and maintain product integrity. The market for pharmaceutical metal detectors is driven by the increasing demand for high-quality pharmaceutical products, stringent regulatory requirements, and the need to minimize product recalls and associated costs. Various types of metal detectors, including electromagnetic induction, X-ray, and microwave metal detectors, are employed in the pharmaceutical industry to detect and eliminate metal contaminants effectively.

Eelectromagnetic Induction Metal Detector, X-ray Metal Detector, Microwave Metal Detector, Others in the Global Pharmaceutical Metal Detector Market:

Electromagnetic induction metal detectors are widely used in the pharmaceutical industry due to their high sensitivity and reliability in detecting metal contaminants. These detectors operate based on the principle of electromagnetic induction, where a magnetic field is generated by passing an electric current through a coil. When a metal object passes through this magnetic field, it induces an electric current in the metal, which is then detected by the system. Electromagnetic induction metal detectors are highly effective in detecting ferrous, non-ferrous, and stainless steel contaminants, making them suitable for various pharmaceutical applications. X-ray metal detectors, on the other hand, utilize X-ray technology to detect metal contaminants in pharmaceutical products. These detectors work by passing X-rays through the product and capturing the resulting image on a detector. The presence of metal contaminants creates a contrast in the image, allowing for their identification and removal. X-ray metal detectors are particularly useful for detecting dense metal contaminants that may not be easily detected by electromagnetic induction metal detectors. Microwave metal detectors operate by emitting microwave radiation and measuring the changes in the reflected signal caused by the presence of metal contaminants. These detectors are highly sensitive and can detect even small metal particles, making them ideal for applications where high precision is required. Other types of metal detectors used in the pharmaceutical industry include magnetic separators and eddy current detectors. Magnetic separators use magnetic fields to attract and remove metal contaminants from the product stream, while eddy current detectors generate an alternating magnetic field to induce electric currents in metal objects, which are then detected by the system. Each type of metal detector has its own advantages and limitations, and the choice of detector depends on the specific requirements of the pharmaceutical manufacturing process.

Pharmaceutical Companies, Others in the Global Pharmaceutical Metal Detector Market:

The usage of metal detectors in the global pharmaceutical market is crucial for ensuring the safety and quality of pharmaceutical products. Pharmaceutical companies rely on these metal detectors to detect and eliminate metal contaminants that may be present in raw materials, intermediate products, or finished products. The presence of metal contaminants can compromise the safety and efficacy of pharmaceutical products, leading to potential health risks for patients. Therefore, the implementation of metal detectors in pharmaceutical manufacturing processes is essential to comply with regulatory standards and maintain product integrity. Metal detectors are used at various stages of the pharmaceutical manufacturing process, including the inspection of raw materials, in-process materials, and finished products. In the inspection of raw materials, metal detectors help identify and remove metal contaminants that may be present in the raw materials before they are used in the manufacturing process. This helps prevent contamination of the final product and ensures that only high-quality raw materials are used. During the manufacturing process, metal detectors are used to inspect in-process materials to detect and remove any metal contaminants that may have been introduced during the production process. This helps maintain the quality and safety of the intermediate products and prevents contamination of the final product. In the inspection of finished products, metal detectors are used to ensure that the final product is free from metal contaminants before it is released to the market. This helps ensure that the pharmaceutical products meet regulatory standards and are safe for patient use. In addition to pharmaceutical companies, other industries that use metal detectors in the pharmaceutical market include contract manufacturing organizations (CMOs), research and development (R&D) laboratories, and regulatory bodies. CMOs use metal detectors to ensure the quality and safety of the pharmaceutical products they manufacture on behalf of pharmaceutical companies. R&D laboratories use metal detectors to ensure the quality and safety of the pharmaceutical products they develop and test. Regulatory bodies use metal detectors to inspect pharmaceutical products and ensure that they meet regulatory standards. Overall, the usage of metal detectors in the global pharmaceutical market is essential for ensuring the safety and quality of pharmaceutical products and maintaining compliance with regulatory standards.

Global Pharmaceutical Metal Detector Market Outlook:

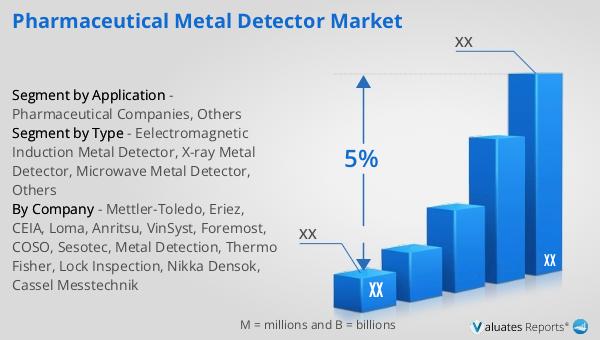

The global pharmaceutical market was valued at approximately 1475 billion USD in 2022, with an expected growth rate of 5% annually over the next six years. This growth is indicative of the increasing demand for pharmaceutical products and the continuous advancements in medical research and technology. In comparison, the chemical drug market has shown a steady increase, growing from 1005 billion USD in 2018 to an estimated 1094 billion USD in 2022. This growth in the chemical drug market highlights the ongoing importance of traditional pharmaceuticals alongside the development of new and innovative treatments. The expansion of both the global pharmaceutical market and the chemical drug market underscores the critical need for stringent quality control measures, such as the use of metal detectors, to ensure the safety and efficacy of pharmaceutical products. As the market continues to grow, the implementation of advanced metal detection technologies will play a vital role in maintaining product integrity and protecting patient health.

| Report Metric | Details |

| Report Name | Pharmaceutical Metal Detector Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mettler-Toledo, Eriez, CEIA, Loma, Anritsu, VinSyst, Foremost, COSO, Sesotec, Metal Detection, Thermo Fisher, Lock Inspection, Nikka Densok, Cassel Messtechnik |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |