What is Global Natural Stone Processing Machinery Market?

The Global Natural Stone Processing Machinery Market refers to the industry that manufactures and sells machinery used to process natural stones like marble, granite, and other types of stone. These machines are essential for cutting, shaping, and polishing stones to be used in construction, decoration, and various other applications. The market includes a wide range of equipment such as CNC machining centers, cutting machines, and polishing machines. These machines are designed to handle the hardness and brittleness of natural stones, ensuring precision and efficiency in the processing tasks. The market is driven by the increasing demand for natural stone in construction and interior design, as well as advancements in machinery technology that enhance productivity and reduce labor costs. The global reach of this market means that manufacturers and suppliers operate in various regions, catering to diverse customer needs and preferences. The market's growth is also influenced by factors such as urbanization, infrastructure development, and the rising popularity of natural stone for aesthetic purposes.

CNC Machining Center, Cutting Machine, Polishing Machine in the Global Natural Stone Processing Machinery Market:

CNC Machining Centers, Cutting Machines, and Polishing Machines are pivotal components of the Global Natural Stone Processing Machinery Market. CNC (Computer Numerical Control) Machining Centers are advanced machines that use computer software to control the movement and operation of cutting tools. These centers are highly precise and can perform complex tasks such as drilling, cutting, and shaping stones with minimal human intervention. They are particularly useful for creating intricate designs and patterns on stones, which are often required in high-end construction and decorative projects. Cutting Machines, on the other hand, are designed specifically to slice through large blocks of stone. These machines use various cutting techniques, including water jet cutting, diamond wire cutting, and laser cutting, to achieve clean and accurate cuts. Water jet cutting uses high-pressure water mixed with abrasive materials to cut through stone, while diamond wire cutting employs a wire embedded with diamond particles to slice through hard materials. Laser cutting, though less common, uses focused laser beams to cut stones with extreme precision. Polishing Machines are used to smooth and shine the surface of stones after they have been cut and shaped. These machines use abrasive pads or belts to grind down the rough edges and bring out the natural luster of the stone. Polishing is a crucial step in stone processing as it enhances the aesthetic appeal and durability of the final product. The efficiency and effectiveness of these machines are vital for meeting the high standards of quality and finish required in the natural stone industry. Together, CNC Machining Centers, Cutting Machines, and Polishing Machines form the backbone of the natural stone processing industry, enabling manufacturers to produce high-quality stone products that meet the diverse needs of their customers.

Marble, Granite, Others in the Global Natural Stone Processing Machinery Market:

The usage of Global Natural Stone Processing Machinery Market spans various types of stones, including marble, granite, and others. Marble is a popular choice for its elegance and timeless beauty. It is widely used in flooring, countertops, and decorative elements in both residential and commercial buildings. The machinery used for processing marble needs to be highly precise to maintain the stone's delicate veining and natural patterns. CNC Machining Centers are particularly useful for creating intricate designs on marble, while cutting machines ensure clean and accurate cuts. Polishing machines are essential for bringing out the natural shine and smoothness of marble surfaces. Granite, on the other hand, is known for its durability and strength. It is commonly used in kitchen countertops, flooring, and exterior cladding. The machinery used for processing granite needs to be robust and powerful to handle the stone's hardness. Diamond wire cutting machines are often used to slice through granite blocks, while CNC Machining Centers help in shaping and drilling the stone. Polishing machines are crucial for achieving a smooth and glossy finish on granite surfaces. Other types of stones, such as limestone, sandstone, and slate, also require specialized machinery for processing. These stones are used in various applications, including paving, wall cladding, and roofing. The machinery used for processing these stones needs to be versatile and adaptable to handle different textures and hardness levels. Cutting machines with adjustable settings are often used to achieve precise cuts, while polishing machines help in enhancing the stone's natural appearance. The Global Natural Stone Processing Machinery Market plays a crucial role in ensuring that these stones are processed efficiently and effectively, meeting the high standards of quality and finish required in the industry.

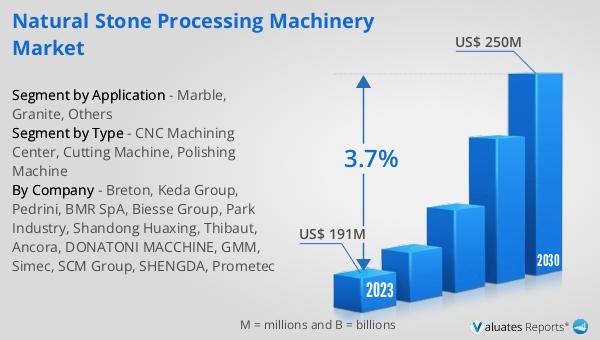

Global Natural Stone Processing Machinery Market Outlook:

The global Natural Stone Processing Machinery market was valued at US$ 191 million in 2023 and is anticipated to reach US$ 250 million by 2030, witnessing a CAGR of 3.7% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by increasing demand for natural stone in various applications such as construction, interior design, and landscaping. The market's growth is also supported by advancements in machinery technology, which enhance productivity and reduce operational costs. The rising popularity of natural stone for its aesthetic appeal and durability further fuels the demand for stone processing machinery. Manufacturers and suppliers in this market are continuously innovating to offer more efficient and precise machines that cater to the diverse needs of their customers. The global reach of this market means that it operates in various regions, each with its own set of challenges and opportunities. Factors such as urbanization, infrastructure development, and economic growth in emerging markets contribute to the increasing demand for natural stone processing machinery. As the market continues to grow, it presents significant opportunities for businesses involved in the production and distribution of these machines.

| Report Metric | Details |

| Report Name | Natural Stone Processing Machinery Market |

| Accounted market size in 2023 | US$ 191 million |

| Forecasted market size in 2030 | US$ 250 million |

| CAGR | 3.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Breton, Keda Group, Pedrini, BMR SpA, Biesse Group, Park Industry, Shandong Huaxing, Thibaut, Ancora, DONATONI MACCHINE, GMM, Simec, SCM Group, SHENGDA, Prometec |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |