What is Global Industrial Single Stage Centrifugal Blower Market?

The Global Industrial Single Stage Centrifugal Blower Market refers to the worldwide industry focused on the production, distribution, and utilization of single-stage centrifugal blowers. These blowers are mechanical devices designed to move air or gas in a single stage, meaning the air or gas passes through one impeller before being discharged. They are widely used in various industrial applications due to their efficiency, reliability, and ability to handle large volumes of air or gas at relatively low pressures. The market encompasses a range of activities, including the manufacturing of different types of blowers, research and development to improve blower technology, and the sale and distribution of these products to various industries. The market is driven by factors such as industrialization, technological advancements, and the need for efficient air and gas handling solutions in sectors like wastewater treatment, petroleum and chemical processing, and power generation. The global reach of this market indicates its importance in supporting industrial operations across different regions, contributing to the overall efficiency and productivity of various industrial processes.

Single Stage Fabricated Centrifugal Blowers, Single Stage Cast Centrifugal Blowers in the Global Industrial Single Stage Centrifugal Blower Market:

Single Stage Fabricated Centrifugal Blowers and Single Stage Cast Centrifugal Blowers are two primary types of blowers within the Global Industrial Single Stage Centrifugal Blower Market. Single Stage Fabricated Centrifugal Blowers are typically constructed from sheet metal or other fabricated materials. These blowers are known for their lightweight design, flexibility in manufacturing, and cost-effectiveness. They are often customized to meet specific industrial requirements and can be designed to handle various types of gases and airflows. The fabrication process allows for a high degree of customization, making these blowers suitable for applications where specific performance characteristics are needed. On the other hand, Single Stage Cast Centrifugal Blowers are made from cast metal, usually cast iron or aluminum. These blowers are known for their durability, strength, and ability to withstand harsh operating conditions. The casting process results in a more robust and rigid structure, making these blowers ideal for heavy-duty applications where reliability and longevity are critical. Cast blowers are often used in environments where they are exposed to high temperatures, corrosive gases, or abrasive materials. Both types of blowers play a crucial role in various industrial processes, providing the necessary airflow and pressure to ensure efficient operation. The choice between fabricated and cast blowers depends on factors such as the specific application requirements, operating conditions, and budget constraints. In the Global Industrial Single Stage Centrifugal Blower Market, manufacturers continuously innovate to improve the performance, efficiency, and reliability of both fabricated and cast blowers. This includes advancements in materials, design, and manufacturing techniques to meet the evolving needs of different industries. The market for these blowers is highly competitive, with numerous players offering a wide range of products to cater to diverse industrial applications. As industries continue to seek efficient and reliable air and gas handling solutions, the demand for both Single Stage Fabricated and Single Stage Cast Centrifugal Blowers is expected to remain strong.

Wastewater Treatment, Petroleum and Chemical, Power Generation, Others in the Global Industrial Single Stage Centrifugal Blower Market:

The Global Industrial Single Stage Centrifugal Blower Market finds extensive usage in various sectors, including wastewater treatment, petroleum and chemical processing, power generation, and others. In wastewater treatment, these blowers are essential for aeration processes, where they provide the necessary airflow to support the biological treatment of wastewater. The blowers help maintain the oxygen levels required for the growth of microorganisms that break down organic matter, ensuring efficient and effective wastewater treatment. In the petroleum and chemical industries, single-stage centrifugal blowers are used for various applications, including gas compression, ventilation, and process air supply. These blowers are critical for maintaining safe and efficient operations, as they help manage the flow of gases and vapors, control temperatures, and ensure proper ventilation in processing plants. The reliability and efficiency of these blowers are crucial in environments where the handling of hazardous and volatile substances is common. In power generation, single-stage centrifugal blowers are used for combustion air supply, cooling, and ventilation. They play a vital role in ensuring the efficient operation of power plants by providing the necessary airflow for combustion processes, cooling systems, and maintaining optimal operating conditions. The blowers help improve the overall efficiency and performance of power generation systems, contributing to the reliable supply of electricity. Other industries that utilize single-stage centrifugal blowers include food and beverage, pharmaceuticals, and manufacturing. In these sectors, the blowers are used for various applications such as drying, material handling, and dust collection. The versatility and efficiency of single-stage centrifugal blowers make them suitable for a wide range of industrial processes, helping to improve productivity and operational efficiency. The demand for these blowers is driven by the need for reliable and efficient air and gas handling solutions across different industries. As industrial processes become more complex and stringent environmental regulations are enforced, the importance of high-performance blowers in ensuring compliance and operational efficiency continues to grow.

Global Industrial Single Stage Centrifugal Blower Market Outlook:

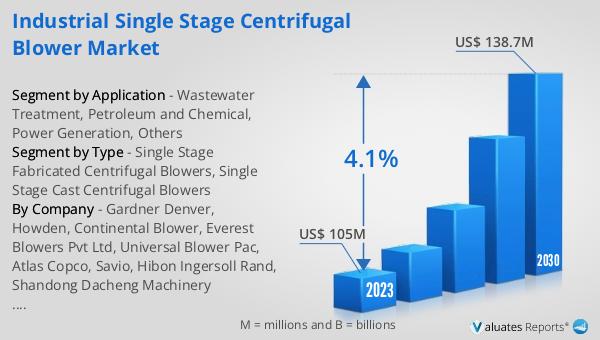

The global Industrial Single Stage Centrifugal Blower market was valued at US$ 105 million in 2023 and is anticipated to reach US$ 138.7 million by 2030, witnessing a CAGR of 4.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by increasing demand for efficient air and gas handling solutions across various industrial sectors. The projected growth reflects the ongoing advancements in blower technology, as well as the rising need for reliable and cost-effective equipment in industries such as wastewater treatment, petroleum and chemical processing, and power generation. The market's expansion is also supported by the continuous efforts of manufacturers to innovate and improve the performance, efficiency, and durability of single-stage centrifugal blowers. As industries strive to enhance their operational efficiency and comply with stringent environmental regulations, the demand for high-quality blowers is expected to remain strong. The market outlook underscores the importance of these blowers in supporting industrial processes and highlights the potential for further growth and development in the coming years.

| Report Metric | Details |

| Report Name | Industrial Single Stage Centrifugal Blower Market |

| Accounted market size in 2023 | US$ 105 million |

| Forecasted market size in 2030 | US$ 138.7 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gardner Denver, Howden, Continental Blower, Everest Blowers Pvt Ltd, Universal Blower Pac, Atlas Copco, Savio, Hibon Ingersoll Rand, Shandong Dacheng Machinery Technology, Atlantic Blowers, Shree Udyog |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |