What is Global Industrial Freeze Drying Equipment Market?

The Global Industrial Freeze Drying Equipment Market refers to the worldwide industry focused on the production and sale of machinery used for freeze drying, also known as lyophilization. This process involves removing moisture from products by freezing them and then reducing the surrounding pressure to allow the frozen water to sublimate directly from the solid phase to the gas phase. Freeze drying is widely used in various industries, including pharmaceuticals, biotechnology, food processing, and environmental applications, due to its ability to preserve the structural integrity and nutritional content of products. The market encompasses a range of equipment, from small-scale laboratory units to large industrial systems, catering to different scales of production and specific industry needs. The demand for freeze drying equipment is driven by the need for long-term preservation of sensitive materials, improved product stability, and the growing emphasis on maintaining the quality of perishable goods. As industries continue to innovate and expand, the Global Industrial Freeze Drying Equipment Market is expected to evolve, offering advanced solutions to meet the diverse requirements of its users.

Industrial-scale, Pilot-scale, Lab-scale in the Global Industrial Freeze Drying Equipment Market:

Industrial-scale, pilot-scale, and lab-scale freeze drying equipment are essential components of the Global Industrial Freeze Drying Equipment Market, each serving distinct purposes based on the scale of production and specific application needs. Industrial-scale freeze drying equipment is designed for large-scale production, typically used in manufacturing facilities where high volumes of products need to be processed efficiently. These systems are robust, capable of handling large batches, and are often integrated into automated production lines to ensure consistency and high throughput. They are commonly used in the food processing industry to preserve large quantities of fruits, vegetables, and other perishable items, as well as in the pharmaceutical industry for the mass production of drugs and vaccines. Pilot-scale freeze drying equipment serves as an intermediate step between laboratory research and full-scale industrial production. These systems are crucial for process development, optimization, and scale-up studies. They allow manufacturers to test and refine their freeze drying processes on a smaller scale before committing to large-scale production. Pilot-scale units are versatile and can be used for a variety of applications, including the development of new pharmaceutical formulations, the testing of food preservation techniques, and the study of environmental samples. They provide valuable data that can be used to improve efficiency, reduce costs, and ensure the quality of the final product. Lab-scale freeze drying equipment is designed for research and development purposes, typically used in academic institutions, research laboratories, and small-scale production facilities. These systems are smaller and more flexible, allowing researchers to experiment with different freeze drying parameters and techniques. Lab-scale units are essential for the initial stages of product development, where small batches of materials are processed to study their behavior during freeze drying. They are commonly used in biotechnology for the preservation of biological samples, in pharmaceuticals for the development of new drugs, and in food science for the study of new preservation methods. Lab-scale freeze drying equipment provides the foundation for innovation and discovery, enabling researchers to explore new possibilities and push the boundaries of what is possible with freeze drying technology. Each scale of freeze drying equipment plays a vital role in the Global Industrial Freeze Drying Equipment Market, catering to the diverse needs of different industries and applications. Industrial-scale systems ensure the efficient processing of large volumes of products, pilot-scale units bridge the gap between research and production, and lab-scale equipment supports innovation and experimentation. Together, these systems contribute to the advancement of freeze drying technology, helping industries preserve the quality and integrity of their products while meeting the growing demand for long-term storage solutions. As the market continues to evolve, the development of new and improved freeze drying equipment will be essential to meet the changing needs of industries and support the ongoing growth of the Global Industrial Freeze Drying Equipment Market.

Biotechnology & Environmental Applications, Pharmaceuticals, Food Processing Industry, Others in the Global Industrial Freeze Drying Equipment Market:

The usage of Global Industrial Freeze Drying Equipment Market spans across various sectors, including biotechnology and environmental applications, pharmaceuticals, the food processing industry, and others. In biotechnology and environmental applications, freeze drying equipment is used to preserve biological samples, such as bacteria, viruses, and cell cultures, for long-term storage and research purposes. This process helps maintain the viability and integrity of these samples, allowing researchers to study them over extended periods without degradation. Additionally, freeze drying is used in environmental science to preserve soil, water, and air samples for analysis, ensuring that the samples remain stable and uncontaminated during storage and transport. In the pharmaceutical industry, freeze drying is a critical process for the production of stable and effective drugs and vaccines. Many pharmaceutical products, especially those that are heat-sensitive or prone to degradation, benefit from freeze drying as it helps maintain their potency and shelf life. Freeze drying equipment is used to produce lyophilized drugs, which are easier to store, transport, and reconstitute when needed. This process is particularly important for the production of biologics, such as monoclonal antibodies and recombinant proteins, which require precise preservation methods to ensure their efficacy. The pharmaceutical industry relies heavily on freeze drying technology to meet regulatory standards and deliver high-quality products to patients. The food processing industry also extensively uses freeze drying equipment to preserve the nutritional content, flavor, and texture of various food products. Freeze drying is a preferred method for preserving fruits, vegetables, meats, and dairy products, as it removes moisture without compromising the quality of the food. This process helps extend the shelf life of perishable items, making them more convenient for consumers and reducing food waste. Freeze-dried foods are lightweight, easy to store, and retain their original taste and nutritional value, making them popular in the market. The food industry continues to innovate with freeze drying technology, developing new products and expanding the range of freeze-dried foods available to consumers. Other applications of freeze drying equipment include the preservation of cultural heritage items, such as historical documents, artworks, and artifacts. Freeze drying is used to restore and preserve these items by removing moisture and preventing further deterioration. This process is particularly valuable for items that have been damaged by water or are at risk of mold and decay. Additionally, freeze drying is used in the production of cosmetics and personal care products, where it helps preserve the stability and effectiveness of active ingredients. The versatility of freeze drying technology makes it a valuable tool across various industries, supporting the preservation and quality of a wide range of products. Overall, the Global Industrial Freeze Drying Equipment Market plays a crucial role in supporting the needs of diverse industries, from biotechnology and pharmaceuticals to food processing and beyond. The ability to preserve the integrity and quality of products through freeze drying technology is essential for meeting the demands of modern consumers and ensuring the long-term stability of sensitive materials. As industries continue to evolve and innovate, the importance of freeze drying equipment will only grow, driving further advancements in this critical market.

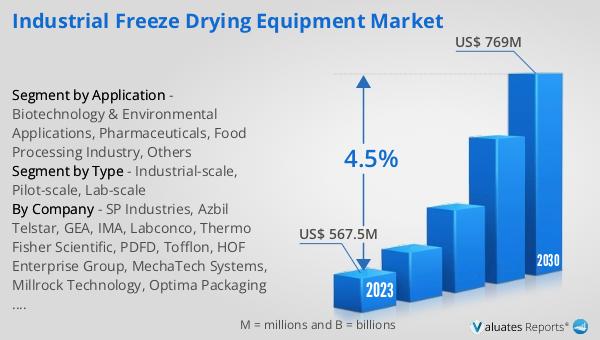

Global Industrial Freeze Drying Equipment Market Outlook:

The global Industrial Freeze Drying Equipment market was valued at US$ 567.5 million in 2023 and is anticipated to reach US$ 769 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the freeze drying equipment industry over the next several years. The increasing demand for high-quality preservation methods across various sectors, including pharmaceuticals, biotechnology, and food processing, is driving this growth. As industries seek to improve the stability and shelf life of their products, the adoption of advanced freeze drying technology is expected to rise. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the efficiency and capabilities of freeze drying equipment. With a compound annual growth rate (CAGR) of 4.5%, the market is set to experience steady growth, reflecting the growing importance of freeze drying technology in preserving the quality and integrity of a wide range of products. This positive market outlook underscores the critical role that freeze drying equipment plays in meeting the evolving needs of industries and supporting the long-term preservation of sensitive materials.

| Report Metric | Details |

| Report Name | Industrial Freeze Drying Equipment Market |

| Accounted market size in 2023 | US$ 567.5 million |

| Forecasted market size in 2030 | US$ 769 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | SP Industries, Azbil Telstar, GEA, IMA, Labconco, Thermo Fisher Scientific, PDFD, Tofflon, HOF Enterprise Group, MechaTech Systems, Millrock Technology, Optima Packaging Group, Martin Christ, Freezedry Specialties, KYOWAC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |