What is Global Hot Melt Gear Pumps for Extrusion Market?

The Global Hot Melt Gear Pumps for Extrusion Market is a specialized segment within the broader industrial machinery market. These pumps are essential for the extrusion process, where materials like plastics, rubber, and adhesives are melted and formed into continuous shapes. Hot melt gear pumps are designed to handle high-viscosity materials at elevated temperatures, ensuring a consistent and precise flow. They are crucial for maintaining the quality and efficiency of the extrusion process, which is widely used in various industries such as packaging, automotive, and construction. The market for these pumps is driven by the increasing demand for high-performance materials and the need for efficient manufacturing processes. Technological advancements and the development of new materials are also contributing to the growth of this market. Companies in this sector are focusing on innovation and customization to meet the specific needs of different applications. The global reach of this market indicates its importance in the manufacturing landscape, with significant contributions from regions like North America, Europe, and Asia-Pacific.

0-50 (cc/rev), 50-200 (cc/rev), 200-500 (cc/rev), Others in the Global Hot Melt Gear Pumps for Extrusion Market:

In the Global Hot Melt Gear Pumps for Extrusion Market, the classification based on the displacement volume of the pumps is crucial for understanding their applications and performance. Pumps with a displacement volume of 0-50 cc/rev are typically used for small-scale operations where precision and control are paramount. These pumps are ideal for applications requiring low flow rates and high accuracy, such as in the production of medical devices or small electronic components. On the other hand, pumps with a displacement volume of 50-200 cc/rev are more versatile and can handle medium-scale operations. They are commonly used in industries like packaging and automotive, where moderate flow rates and consistent performance are essential. These pumps strike a balance between precision and capacity, making them suitable for a wide range of applications. Pumps with a displacement volume of 200-500 cc/rev are designed for large-scale operations that require high flow rates and robust performance. These pumps are often used in heavy industries such as construction and large-scale manufacturing, where the ability to handle large volumes of material efficiently is critical. Finally, the "Others" category includes pumps with displacement volumes outside the standard ranges, catering to specialized applications that require unique specifications. These pumps are often custom-designed to meet the specific needs of niche markets, such as aerospace or advanced materials manufacturing. The diversity in displacement volumes highlights the adaptability and wide-ranging applications of hot melt gear pumps in the extrusion market. Each category serves a distinct purpose, ensuring that manufacturers can find the right pump for their specific needs. This classification also underscores the importance of understanding the technical specifications and operational requirements of different applications to select the most suitable pump. The continuous development and innovation in pump technology are driving the growth and diversification of this market, enabling it to meet the evolving demands of various industries.

Chemical Industry, Food and Beverage Industry, Textile Industry, Others in the Global Hot Melt Gear Pumps for Extrusion Market:

The usage of Global Hot Melt Gear Pumps for Extrusion Market spans several key industries, each with unique requirements and applications. In the chemical industry, these pumps are essential for handling high-viscosity materials such as adhesives, sealants, and coatings. The precise control and consistent flow provided by hot melt gear pumps ensure the quality and performance of chemical products. They are also used in the production of polymers and resins, where maintaining the correct temperature and flow rate is crucial for achieving the desired material properties. In the food and beverage industry, hot melt gear pumps are used for applications such as packaging and labeling. They ensure the accurate dispensing of adhesives and coatings, which is vital for maintaining product quality and safety. These pumps are designed to handle food-grade materials, ensuring compliance with industry standards and regulations. In the textile industry, hot melt gear pumps are used for processes such as lamination and coating. They provide the precise control needed to apply adhesives and coatings uniformly, ensuring the quality and durability of textile products. The ability to handle high-viscosity materials at elevated temperatures makes these pumps ideal for textile applications. Other industries that use hot melt gear pumps include the automotive and construction sectors. In the automotive industry, these pumps are used for applications such as bonding and sealing, where precision and reliability are critical. In the construction industry, they are used for applications such as insulation and waterproofing, where the ability to handle large volumes of material efficiently is essential. The versatility and adaptability of hot melt gear pumps make them valuable tools in a wide range of industries, each with its own set of challenges and requirements. The continuous development and innovation in pump technology are enabling these pumps to meet the evolving demands of different applications, driving the growth of the Global Hot Melt Gear Pumps for Extrusion Market.

Global Hot Melt Gear Pumps for Extrusion Market Outlook:

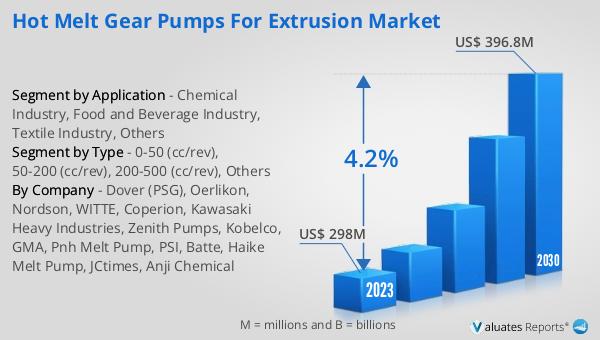

The global Hot Melt Gear Pumps for Extrusion market was valued at US$ 298 million in 2023 and is anticipated to reach US$ 396.8 million by 2030, witnessing a CAGR of 4.2% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for hot melt gear pumps in various industries. The projected growth rate indicates a positive trend, driven by factors such as technological advancements, increasing industrialization, and the need for efficient manufacturing processes. The market's valuation and growth prospects underscore the importance of hot melt gear pumps in the extrusion process, where precision and consistency are crucial. Companies operating in this market are likely to focus on innovation and customization to meet the specific needs of different applications, further driving the market's growth. The global reach of this market, with significant contributions from regions like North America, Europe, and Asia-Pacific, indicates its importance in the manufacturing landscape. The continuous development and innovation in pump technology are expected to play a key role in the market's growth, enabling it to meet the evolving demands of various industries. The market outlook provides valuable insights into the future trends and opportunities in the Global Hot Melt Gear Pumps for Extrusion Market, highlighting the potential for growth and development in this specialized segment.

| Report Metric | Details |

| Report Name | Hot Melt Gear Pumps for Extrusion Market |

| Accounted market size in 2023 | US$ 298 million |

| Forecasted market size in 2030 | US$ 396.8 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dover (PSG), Oerlikon, Nordson, WITTE, Coperion, Kawasaki Heavy Industries, Zenith Pumps, Kobelco, GMA, Pnh Melt Pump, PSI, Batte, Haike Melt Pump, JCtimes, Anji Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |