What is Global High Efficiency Motor Market?

The Global High Efficiency Motor Market refers to the worldwide industry focused on the production and distribution of motors that are designed to operate with higher efficiency compared to standard motors. These motors are engineered to consume less energy while delivering the same or better performance, making them an essential component in various applications where energy conservation and operational efficiency are critical. High efficiency motors are widely used in industries such as manufacturing, automotive, aerospace, and consumer electronics, among others. They help in reducing energy costs, lowering greenhouse gas emissions, and improving overall system performance. The market for these motors is driven by increasing regulatory pressures to reduce energy consumption and carbon footprints, advancements in motor technology, and the growing awareness of the benefits of energy-efficient solutions. As industries continue to seek ways to enhance productivity while minimizing environmental impact, the demand for high efficiency motors is expected to grow steadily.

Brushed Motor, Brushless Motor, Stepper Motor in the Global High Efficiency Motor Market:

In the Global High Efficiency Motor Market, different types of motors play crucial roles, including Brushed Motors, Brushless Motors, and Stepper Motors. Brushed Motors are traditional electric motors that use brushes to deliver current to the motor windings through a commutator. They are known for their simplicity, cost-effectiveness, and ease of control. However, they tend to have shorter lifespans due to brush wear and require more maintenance. Despite these drawbacks, brushed motors are still widely used in applications where cost and simplicity are more critical than longevity and efficiency. On the other hand, Brushless Motors, as the name suggests, do not use brushes. Instead, they rely on electronic commutation to deliver current to the motor windings. This design eliminates the wear and tear associated with brushes, resulting in longer lifespans, higher efficiency, and lower maintenance requirements. Brushless motors are commonly used in applications where reliability and performance are paramount, such as in electric vehicles, drones, and high-end industrial machinery. Stepper Motors are another type of motor used in the high efficiency motor market. These motors are designed to move in discrete steps, allowing for precise control of position and speed. They are widely used in applications that require accurate positioning, such as in 3D printers, CNC machines, and robotics. Stepper motors offer high torque at low speeds and excellent repeatability, making them ideal for tasks that demand precision. Each of these motor types has its own set of advantages and disadvantages, and the choice of motor depends on the specific requirements of the application. The global market for high efficiency motors continues to evolve as new technologies emerge and industries seek more efficient and reliable solutions.

Medical Equipment, Instrumentation, Electric Tool, Industrial Automation, Aerospace and Transportation in the Global High Efficiency Motor Market:

The Global High Efficiency Motor Market finds extensive usage across various sectors, including Medical Equipment, Instrumentation, Electric Tools, Industrial Automation, Aerospace, and Transportation. In the medical field, high efficiency motors are crucial for the operation of devices such as MRI machines, ventilators, and surgical robots. These motors ensure that medical equipment operates reliably and efficiently, which is vital for patient care and safety. In instrumentation, high efficiency motors are used in precision instruments that require accurate and consistent performance, such as laboratory equipment and analytical devices. These motors help in achieving high levels of precision and reliability, which are essential for scientific research and quality control. Electric tools, such as drills, saws, and grinders, also benefit from high efficiency motors. These motors provide the necessary power and torque while consuming less energy, resulting in longer battery life and reduced operational costs. In the realm of industrial automation, high efficiency motors are used in various automated systems and machinery, including conveyor belts, robotic arms, and assembly lines. These motors enhance the efficiency and productivity of manufacturing processes, leading to cost savings and improved product quality. The aerospace industry relies on high efficiency motors for applications such as aircraft actuators, control systems, and unmanned aerial vehicles (UAVs). These motors contribute to the overall performance and reliability of aerospace systems, which is critical for safety and mission success. In transportation, high efficiency motors are used in electric and hybrid vehicles, trains, and ships. They help in reducing fuel consumption and emissions, contributing to a more sustainable and environmentally friendly transportation system. Overall, the usage of high efficiency motors in these areas highlights their importance in enhancing performance, reducing energy consumption, and minimizing environmental impact.

Global High Efficiency Motor Market Outlook:

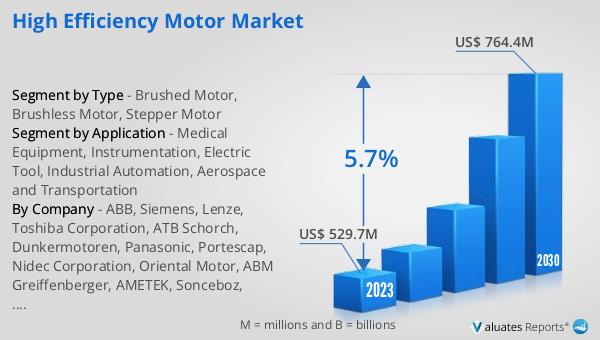

The global High Efficiency Motor market was valued at US$ 529.7 million in 2023 and is anticipated to reach US$ 764.4 million by 2030, witnessing a CAGR of 5.7% during the forecast period 2024-2030. This growth reflects the increasing demand for energy-efficient solutions across various industries. High efficiency motors are becoming more popular due to their ability to reduce energy consumption, lower operational costs, and minimize environmental impact. As industries continue to prioritize sustainability and cost-effectiveness, the adoption of high efficiency motors is expected to rise. The market's growth is also driven by advancements in motor technology, regulatory pressures to reduce energy consumption, and the growing awareness of the benefits of energy-efficient solutions. The increasing use of high efficiency motors in applications such as medical equipment, instrumentation, electric tools, industrial automation, aerospace, and transportation further underscores their importance in today's world. As a result, the global High Efficiency Motor market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | High Efficiency Motor Market |

| Accounted market size in 2023 | US$ 529.7 million |

| Forecasted market size in 2030 | US$ 764.4 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, Siemens, Lenze, Toshiba Corporation, ATB Schorch, Dunkermotoren, Panasonic, Portescap, Nidec Corporation, Oriental Motor, ABM Greiffenberger, AMETEK, Sonceboz, Lafert, Allied Motion Technologies, Johnson Electric, Mabuchi Motor, Shenzhen Topband, Maxon Motor, Adamant Namiki Precision Jewel, C.I. TAKIRON, Moons' Industries, Sinbad Motor, Constar Motion, Citizen Micro, Autotrol, Hennkwell, Autonics, ISL Products, Shenzhen Zhaowei |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |