What is Global Heat Recovery Device Market?

The global Heat Recovery Device market is a rapidly evolving sector that focuses on the development and deployment of technologies designed to capture and reuse waste heat from various industrial processes. These devices are essential for improving energy efficiency and reducing greenhouse gas emissions. By recovering heat that would otherwise be lost, these systems can significantly lower energy costs and enhance the overall sustainability of industrial operations. The market encompasses a wide range of products, including heat exchangers, recuperators, regenerators, and economizers, each tailored to specific applications and industries. The growing emphasis on energy conservation and stringent environmental regulations are key drivers for the adoption of heat recovery devices globally. Industries such as power generation, chemical processing, and manufacturing are increasingly investing in these technologies to optimize their energy use and minimize their environmental footprint. As a result, the global Heat Recovery Device market is poised for substantial growth, driven by technological advancements and the increasing need for sustainable industrial practices.

Vertical, Horizontal in the Global Heat Recovery Device Market:

In the context of the Global Heat Recovery Device Market, the terms "vertical" and "horizontal" refer to the orientation and application of heat recovery devices in various industrial settings. Vertical heat recovery devices are typically designed for applications where space is limited, and the heat source is located at a higher elevation. These devices are often used in industries such as power generation, where they can be integrated into existing vertical structures like chimneys or exhaust stacks. Vertical heat recovery systems are advantageous because they can efficiently capture and transfer heat from high-temperature exhaust gases, which are often released at elevated points in industrial facilities. This orientation allows for the effective utilization of gravitational forces to facilitate the flow of heat and improve the overall efficiency of the system. On the other hand, horizontal heat recovery devices are designed for applications where the heat source is spread out over a larger area or where the exhaust gases are released at lower elevations. These systems are commonly used in industries such as chemical processing, where large horizontal surfaces are available for the installation of heat exchangers and other recovery equipment. Horizontal heat recovery devices are particularly effective in capturing and reusing heat from processes that generate low to medium temperature exhaust gases. The horizontal orientation allows for the installation of larger heat exchange surfaces, which can enhance the efficiency of heat transfer and improve the overall performance of the system. Both vertical and horizontal heat recovery devices play a crucial role in optimizing energy use and reducing emissions in various industrial applications. The choice between vertical and horizontal systems depends on several factors, including the specific requirements of the industrial process, the available space for installation, and the temperature and flow characteristics of the exhaust gases. In many cases, a combination of both vertical and horizontal heat recovery devices may be used to achieve the best results. For example, a power plant might use vertical heat recovery systems to capture high-temperature exhaust gases from its boilers, while also employing horizontal systems to recover heat from lower temperature processes such as cooling water or flue gas desulfurization units. The integration of both types of systems can maximize the overall efficiency of the heat recovery process and contribute to significant energy savings and emission reductions. In summary, the Global Heat Recovery Device Market encompasses a wide range of technologies and applications, with vertical and horizontal heat recovery devices playing a key role in enhancing energy efficiency and sustainability in various industrial sectors. The choice between vertical and horizontal systems depends on the specific needs and constraints of the industrial process, and the effective integration of both types of devices can lead to substantial improvements in energy use and environmental performance.

Residential Building, Commercial Building, Industrial Building in the Global Heat Recovery Device Market:

The usage of heat recovery devices in residential, commercial, and industrial buildings varies significantly based on the specific energy needs and operational characteristics of each type of building. In residential buildings, heat recovery devices are primarily used to improve indoor air quality and reduce energy consumption. Heat recovery ventilation (HRV) systems are commonly installed in homes to capture heat from exhaust air and use it to preheat incoming fresh air. This process not only reduces the energy required for heating but also ensures a constant supply of fresh air, which is essential for maintaining a healthy indoor environment. HRV systems are particularly beneficial in cold climates, where they can significantly reduce heating costs during the winter months. In commercial buildings, heat recovery devices are used to optimize the energy efficiency of heating, ventilation, and air conditioning (HVAC) systems. Large office buildings, shopping malls, and hotels often have complex HVAC systems that consume a significant amount of energy. By integrating heat recovery devices into these systems, it is possible to capture waste heat from exhaust air, refrigeration units, and other sources, and reuse it for heating or preheating purposes. This can lead to substantial energy savings and lower operating costs for commercial building owners. Additionally, heat recovery devices can help commercial buildings meet stringent energy efficiency standards and reduce their carbon footprint. In industrial buildings, heat recovery devices are used to capture and reuse waste heat from various manufacturing processes. Industries such as chemical processing, food and beverage production, and metal fabrication generate large amounts of waste heat that can be recovered and reused to improve overall energy efficiency. For example, in a chemical plant, heat recovery devices can capture heat from high-temperature exhaust gases and use it to preheat raw materials or generate steam for other processes. This not only reduces the energy required for heating but also enhances the overall efficiency of the production process. In the food and beverage industry, heat recovery devices can capture heat from ovens, fryers, and other equipment, and use it for preheating water or air, thereby reducing energy consumption and operating costs. In summary, the usage of heat recovery devices in residential, commercial, and industrial buildings plays a crucial role in improving energy efficiency and reducing operating costs. In residential buildings, HRV systems enhance indoor air quality and reduce heating costs. In commercial buildings, heat recovery devices optimize HVAC systems and help meet energy efficiency standards. In industrial buildings, these devices capture and reuse waste heat from manufacturing processes, leading to significant energy savings and improved production efficiency. The adoption of heat recovery devices across these different types of buildings is driven by the need to reduce energy consumption, lower operating costs, and minimize environmental impact.

Global Heat Recovery Device Market Outlook:

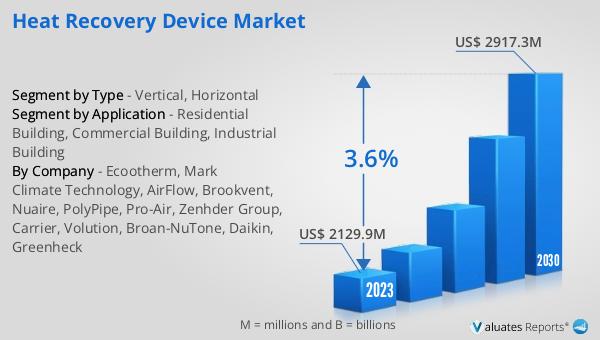

The global Heat Recovery Device market was valued at US$ 2129.9 million in 2023 and is anticipated to reach US$ 2917.3 million by 2030, witnessing a CAGR of 3.6% during the forecast period from 2024 to 2030. According to our Construction Machinery research center, sales of construction machinery in Europe increased by 24% in 2021. In 2022, the construction machinery revenue in Europe was about US$ 22 billion, while the US market sold approximately US$ 36 billion in construction machinery in the same year. This growth in construction machinery sales is indicative of the broader economic trends and the increasing demand for energy-efficient technologies, including heat recovery devices. The rising investments in construction and infrastructure projects across various regions are expected to drive the demand for heat recovery devices, as these technologies are essential for improving energy efficiency and reducing operational costs in new and existing buildings. The integration of heat recovery devices in construction projects not only enhances the sustainability of buildings but also helps in meeting stringent energy efficiency standards and regulations. As a result, the global Heat Recovery Device market is poised for significant growth, supported by the ongoing advancements in technology and the increasing focus on sustainable development.

| Report Metric | Details |

| Report Name | Heat Recovery Device Market |

| Accounted market size in 2023 | US$ 2129.9 million |

| Forecasted market size in 2030 | US$ 2917.3 million |

| CAGR | 3.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ecootherm, Mark Climate Technology, AirFlow, Brookvent, Nuaire, PolyPipe, Pro-Air, Zenhder Group, Carrier, Volution, Broan-NuTone, Daikin, Greenheck |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |