What is Global Flow Control Plunger Valve Market?

The Global Flow Control Plunger Valve Market refers to the industry focused on the production, distribution, and application of plunger valves designed to regulate the flow of various fluids. These valves are essential components in numerous industrial processes, ensuring precise control over fluid dynamics. Plunger valves are particularly valued for their ability to handle high-pressure environments and their durability in harsh conditions. They are used in a wide range of sectors, including water treatment, power plants, and water distribution systems. The market encompasses various types of plunger valves, each tailored to specific applications and operational requirements. As industries continue to seek efficient and reliable flow control solutions, the demand for advanced plunger valves is expected to grow, driving innovation and development within this market.

Metal Seal, Non-Metallic Seal in the Global Flow Control Plunger Valve Market:

In the Global Flow Control Plunger Valve Market, seals play a crucial role in ensuring the efficiency and reliability of the valves. There are two primary types of seals used in these valves: metal seals and non-metallic seals. Metal seals are typically made from materials such as stainless steel, Inconel, or other high-strength alloys. These seals are known for their durability and ability to withstand extreme temperatures and pressures. They are often used in applications where the valve is exposed to harsh conditions, such as in power plants or chemical processing facilities. Metal seals provide a tight, leak-proof seal that ensures the valve operates efficiently and safely. On the other hand, non-metallic seals are made from materials like rubber, PTFE (polytetrafluoroethylene), or other synthetic polymers. These seals are more flexible and can provide a better seal in applications where the valve needs to accommodate slight misalignments or movements. Non-metallic seals are often used in water treatment and distribution systems, where the operating conditions are less extreme but still require reliable sealing performance. Both types of seals have their advantages and are chosen based on the specific requirements of the application. The choice between metal and non-metallic seals depends on factors such as the operating environment, the type of fluid being controlled, and the desired lifespan of the valve. In summary, the Global Flow Control Plunger Valve Market relies on both metal and non-metallic seals to ensure the efficient and reliable operation of plunger valves across various industries.

Water Treatment, Power Plants, Water Distribution, Others in the Global Flow Control Plunger Valve Market:

The Global Flow Control Plunger Valve Market finds extensive usage in several critical areas, including water treatment, power plants, water distribution, and other industrial applications. In water treatment facilities, plunger valves are essential for regulating the flow of water through various stages of the treatment process. They help maintain the correct pressure and flow rates, ensuring that the water is properly filtered, treated, and distributed. These valves are designed to handle the varying pressures and flow rates encountered in water treatment plants, providing reliable and efficient control. In power plants, plunger valves are used to control the flow of steam, water, and other fluids within the plant. They play a crucial role in maintaining the efficiency and safety of the plant's operations. By precisely regulating the flow of fluids, these valves help optimize the performance of turbines, boilers, and other critical equipment. In water distribution systems, plunger valves are used to manage the flow of water from treatment plants to end-users. They help maintain consistent pressure and flow rates throughout the distribution network, ensuring that water is delivered efficiently and reliably to homes, businesses, and other facilities. These valves are designed to withstand the demands of large-scale distribution systems, providing long-lasting and dependable performance. Other industrial applications of plunger valves include chemical processing, oil and gas production, and manufacturing. In these industries, plunger valves are used to control the flow of various fluids, ensuring precise and reliable operation of complex processes. The versatility and durability of plunger valves make them an essential component in a wide range of industrial applications.

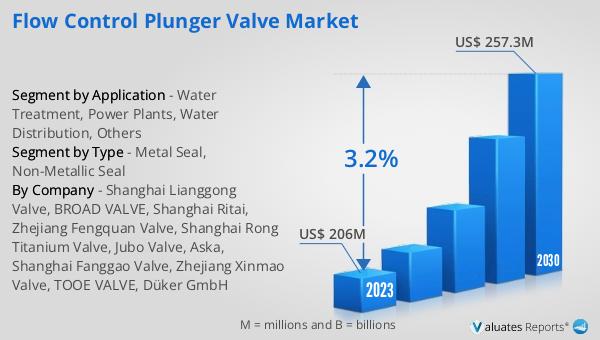

Global Flow Control Plunger Valve Market Outlook:

The global Flow Control Plunger Valve market was valued at US$ 206 million in 2023 and is anticipated to reach US$ 257.3 million by 2030, witnessing a CAGR of 3.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by increasing demand for efficient and reliable flow control solutions across various sectors. The projected growth reflects the ongoing advancements in valve technology and the expanding applications of plunger valves in industries such as water treatment, power generation, and water distribution. As industries continue to prioritize efficiency and reliability in their operations, the demand for high-quality plunger valves is expected to rise. This growth is also supported by the increasing investments in infrastructure development and the modernization of existing facilities. The market's steady CAGR of 3.2% underscores the importance of plunger valves in maintaining the efficiency and safety of critical industrial processes. Overall, the Global Flow Control Plunger Valve Market is poised for significant growth in the coming years, driven by the need for advanced flow control solutions in various industries.

| Report Metric | Details |

| Report Name | Flow Control Plunger Valve Market |

| Accounted market size in 2023 | US$ 206 million |

| Forecasted market size in 2030 | US$ 257.3 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shanghai Lianggong Valve, BROAD VALVE, Shanghai Ritai, Zhejiang Fengquan Valve, Shanghai Rong Titanium Valve, Jubo Valve, Aska, Shanghai Fanggao Valve, Zhejiang Xinmao Valve, TOOE VALVE, Düker GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |