What is Global Fixed Welding Fume Extractor Market?

The Global Fixed Welding Fume Extractor Market refers to the industry focused on the production and distribution of devices designed to remove harmful fumes generated during welding processes. These extractors are crucial for maintaining a safe working environment by capturing and filtering out toxic particles and gases that are released when metals are welded together. The market encompasses a variety of products, including portable and fixed systems, each tailored to different industrial needs. Fixed welding fume extractors are typically installed in a permanent location within a workshop or factory and are connected to multiple welding stations through ductwork. These systems are essential in industries where welding is a frequent activity, such as automotive manufacturing, shipbuilding, and construction. By ensuring cleaner air, these extractors help protect workers' health, comply with occupational safety regulations, and improve overall productivity. The market is driven by increasing awareness of workplace safety, stringent environmental regulations, and the growing demand for high-quality welding in various industries.

Automatic Cleaning, Manual Cleaning in the Global Fixed Welding Fume Extractor Market:

In the Global Fixed Welding Fume Extractor Market, there are two primary types of cleaning mechanisms: automatic cleaning and manual cleaning. Automatic cleaning systems are designed to operate with minimal human intervention. They typically use mechanisms such as reverse air pulses, vibration, or mechanical shakers to dislodge and remove accumulated dust and particles from the filters. These systems are highly efficient and can maintain optimal performance over extended periods, making them ideal for large-scale industrial operations where continuous welding activities generate significant amounts of fumes. Automatic cleaning systems reduce downtime and maintenance costs, as they do not require frequent manual intervention. On the other hand, manual cleaning systems rely on human operators to clean the filters. This process usually involves removing the filters from the extractor, cleaning them using compressed air or washing them, and then reinstalling them. While manual cleaning systems are generally less expensive to purchase and install, they can be labor-intensive and may lead to increased downtime if not managed properly. They are more suitable for smaller operations or workshops where welding activities are not as frequent or intense. Both types of systems have their advantages and disadvantages, and the choice between them often depends on the specific needs and resources of the business. In summary, automatic cleaning systems offer convenience and efficiency for high-volume operations, while manual cleaning systems provide a cost-effective solution for smaller-scale applications.

Arc Welding, Resistance Welding, Laser Beam Welding, Oxy Fuel Welding, Robot Welding in the Global Fixed Welding Fume Extractor Market:

The Global Fixed Welding Fume Extractor Market finds its usage across various welding techniques, including Arc Welding, Resistance Welding, Laser Beam Welding, Oxy-Fuel Welding, and Robot Welding. In Arc Welding, which is one of the most common welding methods, an electric arc is used to melt and join metals. This process generates a significant amount of fumes, making fume extractors essential to ensure a safe working environment. Fixed welding fume extractors are installed near the welding stations to capture and filter out the hazardous particles and gases produced during the welding process. Resistance Welding, which involves the application of pressure and passing an electric current through the metal pieces to be joined, also produces fumes that need to be managed. Fixed fume extractors help in maintaining air quality by removing these fumes, thereby protecting workers' health and complying with safety regulations. Laser Beam Welding, which uses a laser to melt the materials being joined, generates fumes that can be harmful if inhaled. Fixed fume extractors are crucial in capturing these fumes at the source, ensuring that the work environment remains safe and clean. Oxy-Fuel Welding, which uses a combination of oxygen and fuel gases to weld and cut metals, produces a variety of fumes and gases that need to be controlled. Fixed welding fume extractors are effective in capturing these emissions, preventing them from spreading throughout the workspace. Lastly, Robot Welding, which involves the use of automated welding machines, also generates fumes that need to be managed. Fixed fume extractors are integrated into the welding cells to capture and filter out the fumes, ensuring that the automated systems can operate efficiently without compromising air quality. In all these welding techniques, fixed welding fume extractors play a vital role in maintaining a safe and healthy working environment by effectively managing the fumes generated during the welding processes.

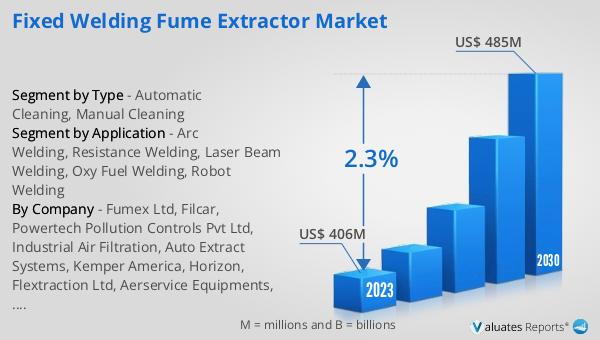

Global Fixed Welding Fume Extractor Market Outlook:

The global Fixed Welding Fume Extractor market was valued at US$ 406 million in 2023 and is anticipated to reach US$ 485 million by 2030, witnessing a CAGR of 2.3% during the forecast period 2024-2030. This market growth is driven by increasing awareness of workplace safety, stringent environmental regulations, and the growing demand for high-quality welding in various industries. Fixed welding fume extractors are essential in industries where welding is a frequent activity, such as automotive manufacturing, shipbuilding, and construction. These systems help protect workers' health by capturing and filtering out toxic particles and gases released during welding processes. They also ensure compliance with occupational safety regulations and improve overall productivity. The market encompasses a variety of products, including portable and fixed systems, each tailored to different industrial needs. Fixed welding fume extractors are typically installed in a permanent location within a workshop or factory and are connected to multiple welding stations through ductwork. By ensuring cleaner air, these extractors contribute to a safer and more efficient working environment. The market is expected to continue growing as industries increasingly prioritize worker safety and environmental sustainability.

| Report Metric | Details |

| Report Name | Fixed Welding Fume Extractor Market |

| Accounted market size in 2023 | US$ 406 million |

| Forecasted market size in 2030 | US$ 485 million |

| CAGR | 2.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fumex Ltd, Filcar, Powertech Pollution Controls Pvt Ltd, Industrial Air Filtration, Auto Extract Systems, Kemper America, Horizon, Flextraction Ltd, Aerservice Equipments, Plymovent |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |