What is Global Copper Foil For High Speed Transmission Market?

The Global Copper Foil for High-Speed Transmission Market is a specialized segment within the broader copper foil industry, focusing on the production and application of copper foils designed for high-speed data transmission. These copper foils are essential components in various electronic devices and systems that require rapid and reliable data transfer. The market encompasses a range of products, including different types of copper foils such as RTF (Reverse Treated Foil), VLP (Very Low Profile) copper foil, and others, each tailored to meet specific performance criteria. The demand for these high-performance copper foils is driven by the increasing need for faster and more efficient communication technologies, particularly in sectors like telecommunications, data centers, and consumer electronics. As the world becomes more interconnected and reliant on digital communication, the importance of high-speed transmission capabilities continues to grow, thereby fueling the demand for advanced copper foil solutions. This market is characterized by continuous innovation and development, as manufacturers strive to enhance the performance, durability, and cost-effectiveness of their products to meet the evolving needs of the industry.

RTF Copper Foil, VLP Copper Foil, Others in the Global Copper Foil For High Speed Transmission Market:

RTF Copper Foil, VLP Copper Foil, and other types of copper foils play crucial roles in the Global Copper Foil for High-Speed Transmission Market. RTF Copper Foil, or Reverse Treated Foil, is a type of copper foil that undergoes a special treatment process to improve its adhesion properties. This treatment involves applying a roughened surface on one side of the foil, which enhances its bonding strength with substrates used in printed circuit boards (PCBs). RTF Copper Foil is particularly valued for its ability to provide excellent peel strength and reliability in high-frequency applications, making it a preferred choice for high-speed data transmission systems. On the other hand, VLP Copper Foil, or Very Low Profile Copper Foil, is designed to offer minimal surface roughness while maintaining high conductivity. The smooth surface of VLP Copper Foil reduces signal loss and electromagnetic interference, which are critical factors in high-speed data transmission. This type of copper foil is often used in applications where signal integrity and performance are paramount, such as in advanced communication systems and high-frequency circuits. Besides RTF and VLP Copper Foils, the market also includes other specialized copper foils that cater to specific requirements. These may include ultra-thin copper foils, which are used in flexible electronics and miniaturized devices, and high-strength copper foils, which are designed to withstand harsh environmental conditions. Each type of copper foil offers unique advantages and is selected based on the specific needs of the application. The continuous development and innovation in copper foil technology are driven by the growing demand for faster and more reliable data transmission. As electronic devices become more sophisticated and the need for high-speed communication increases, the importance of high-performance copper foils in ensuring efficient and reliable data transfer cannot be overstated. Manufacturers in this market are constantly exploring new materials, treatment processes, and production techniques to enhance the performance and cost-effectiveness of their products. This ongoing innovation is essential to meet the evolving demands of the industry and to support the development of next-generation communication technologies.

Communication Base Station, Server, Consumer Electronics, Others in the Global Copper Foil For High Speed Transmission Market:

The usage of Global Copper Foil for High-Speed Transmission Market spans various critical areas, including Communication Base Stations, Servers, Consumer Electronics, and others. In Communication Base Stations, copper foils are integral components in the construction of PCBs that manage high-frequency signals. These base stations are the backbone of mobile networks, enabling seamless communication between mobile devices and the network infrastructure. High-performance copper foils ensure that these base stations can handle large volumes of data with minimal signal loss and interference, thereby enhancing the overall efficiency and reliability of mobile networks. In Servers, which are the central hubs of data centers, copper foils are used in the PCBs that facilitate high-speed data processing and storage. The demand for faster and more efficient servers is driven by the exponential growth of data generated by various digital activities. High-quality copper foils help in maintaining signal integrity and reducing latency, which are crucial for the optimal performance of servers. In the realm of Consumer Electronics, copper foils are used in a wide range of devices, from smartphones and tablets to laptops and wearable technology. These devices require compact and efficient PCBs that can support high-speed data transmission for various functions, such as internet browsing, video streaming, and gaming. The use of advanced copper foils ensures that these devices can deliver high performance while maintaining energy efficiency and durability. Beyond these specific areas, copper foils are also used in other applications that require high-speed data transmission, such as automotive electronics, aerospace systems, and industrial machinery. In automotive electronics, for instance, copper foils are used in the PCBs that control various functions, including navigation, entertainment, and safety systems. The ability to transmit data quickly and reliably is essential for the performance and safety of modern vehicles. Similarly, in aerospace systems, copper foils are used in the PCBs that manage communication and control systems, where reliability and performance are critical. In industrial machinery, high-speed data transmission is necessary for the efficient operation of automated systems and equipment. The versatility and performance of copper foils make them indispensable in these diverse applications, highlighting their importance in the modern digital world.

Global Copper Foil For High Speed Transmission Market Outlook:

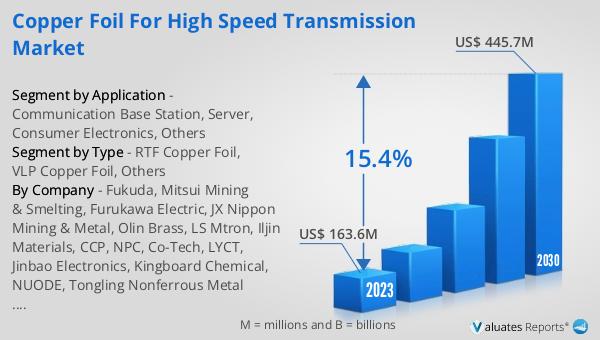

The global Copper Foil for High-Speed Transmission market was valued at US$ 163.6 million in 2023 and is anticipated to reach US$ 445.7 million by 2030, witnessing a CAGR of 15.4% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for high-performance copper foils in various applications, driven by the need for faster and more reliable data transmission. The market's expansion is fueled by advancements in communication technologies, the proliferation of data centers, and the growing adoption of consumer electronics that require efficient and high-speed data transfer capabilities. As industries continue to evolve and the demand for high-speed communication intensifies, the importance of high-quality copper foils in ensuring optimal performance and reliability becomes even more pronounced. The projected growth of the market underscores the critical role that copper foils play in supporting the development and deployment of next-generation communication systems and electronic devices.

| Report Metric | Details |

| Report Name | Copper Foil For High Speed Transmission Market |

| Accounted market size in 2023 | US$ 163.6 million |

| Forecasted market size in 2030 | US$ 445.7 million |

| CAGR | 15.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fukuda, Mitsui Mining & Smelting, Furukawa Electric, JX Nippon Mining & Metal, Olin Brass, LS Mtron, Iljin Materials, CCP, NPC, Co-Tech, LYCT, Jinbao Electronics, Kingboard Chemical, NUODE, Tongling Nonferrous Metal Group, Jiangxi JCC Copper Foil Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |