What is Global Belt Weigher Market?

The Global Belt Weigher Market refers to the industry focused on the production, distribution, and utilization of belt weighers, which are devices used to measure the flow rate of material traveling over a conveyor belt. These instruments are essential in various industries for ensuring accurate and efficient material handling. Belt weighers are designed to provide real-time data on the weight of the material being transported, which helps in maintaining process control, optimizing production, and reducing waste. They are widely used in sectors such as mining, power generation, cement manufacturing, and food processing, among others. The market for belt weighers is driven by the need for precise measurement and control in material handling processes, as well as the increasing demand for automation and efficiency in industrial operations. Technological advancements and the integration of digital solutions are also contributing to the growth of the global belt weigher market.

Single-Idler, Two-Idler, Three-Idler, Four-Idler, Multi-Idler in the Global Belt Weigher Market:

In the Global Belt Weigher Market, different types of belt weighers are categorized based on the number of idlers they use: Single-Idler, Two-Idler, Three-Idler, Four-Idler, and Multi-Idler. Single-Idler belt weighers are the simplest form, consisting of a single weighing idler that measures the load on the belt. They are typically used in applications where high accuracy is not critical, and the material flow is relatively consistent. These weighers are cost-effective and easy to install, making them suitable for smaller operations or where budget constraints are a concern. Two-Idler belt weighers, on the other hand, provide a higher level of accuracy by using two idlers to measure the load. This configuration helps in averaging out the weight measurements, reducing the impact of belt tension and material distribution variations. They are commonly used in medium-sized operations where a balance between cost and accuracy is required. Three-Idler belt weighers further enhance accuracy by incorporating three idlers, which provide even more data points for averaging the weight measurements. This setup is ideal for applications where precise measurement is crucial, such as in the mining and aggregate industries. Four-Idler belt weighers take accuracy to an even higher level by using four idlers. This configuration minimizes the effects of belt tension, material distribution, and other variables, making them suitable for high-precision applications in industries like cement and steel manufacturing. Multi-Idler belt weighers, which use more than four idlers, offer the highest level of accuracy and are used in applications where extremely precise measurement is necessary. These weighers are often found in large-scale industrial operations where the cost of inaccuracies can be significant. Each type of belt weigher has its own advantages and is chosen based on the specific requirements of the application, including the desired level of accuracy, budget, and operational constraints.

Power (including coal), Cement, Steel, Aggregate, Mining, Pulp & Paper, Food, Chemical, Water/ Waste Water in the Global Belt Weigher Market:

The Global Belt Weigher Market finds extensive usage across various industries, including Power (such as coal), Cement, Steel, Aggregate, Mining, Pulp & Paper, Food, Chemical, and Water/Waste Water. In the power industry, particularly in coal-fired power plants, belt weighers are used to measure the amount of coal being fed into the boilers. Accurate measurement is crucial for maintaining the efficiency of the combustion process and ensuring optimal power generation. In the cement industry, belt weighers are used to monitor the flow of raw materials like limestone and clinker, as well as the finished product. This helps in maintaining the quality of the cement and optimizing the production process. The steel industry uses belt weighers to measure the flow of raw materials such as iron ore and coke, as well as the finished steel products. This ensures that the production process is efficient and that the final product meets the required specifications. In the aggregate industry, belt weighers are used to measure the flow of materials like sand, gravel, and crushed stone. This helps in maintaining the quality of the aggregate and optimizing the production process. The mining industry relies heavily on belt weighers to measure the flow of extracted materials such as coal, ore, and minerals. Accurate measurement is crucial for maintaining the efficiency of the extraction process and ensuring optimal resource utilization. In the pulp and paper industry, belt weighers are used to measure the flow of raw materials like wood chips and pulp, as well as the finished paper products. This helps in maintaining the quality of the paper and optimizing the production process. The food industry uses belt weighers to measure the flow of ingredients and finished products, ensuring that the production process is efficient and that the final product meets the required specifications. In the chemical industry, belt weighers are used to measure the flow of raw materials and finished products, ensuring that the production process is efficient and that the final product meets the required specifications. In the water and wastewater industry, belt weighers are used to measure the flow of materials like sludge and chemicals, ensuring that the treatment process is efficient and that the final product meets the required specifications. Overall, the Global Belt Weigher Market plays a crucial role in ensuring the efficiency and accuracy of material handling processes across various industries.

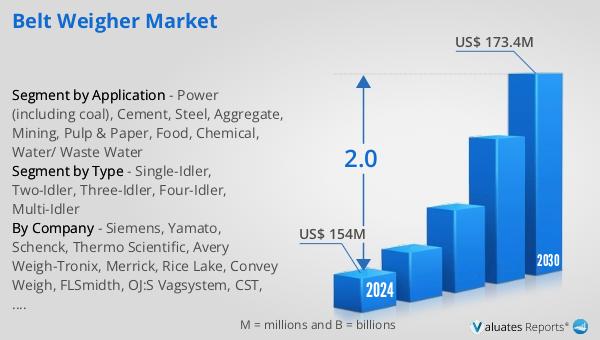

Global Belt Weigher Market Outlook:

The global Belt Weigher market is anticipated to grow from an estimated US$ 154 million in 2024 to reach US$ 173.4 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.0% over the forecast period. This growth is driven by the increasing demand for accurate and efficient material handling solutions across various industries. Belt weighers are essential for maintaining process control, optimizing production, and reducing waste, which are critical factors for industrial operations. The market is characterized by the presence of several key players, with the top three companies accounting for approximately 40% of the global market share. These leading players are focused on continuous innovation and the integration of advanced technologies to enhance the performance and accuracy of belt weighers. The competitive landscape of the market is shaped by factors such as product quality, technological advancements, and customer service. Companies are investing in research and development to introduce new and improved belt weighers that cater to the evolving needs of different industries. Additionally, strategic partnerships, mergers, and acquisitions are common strategies adopted by market players to expand their market presence and strengthen their product portfolios. The growing emphasis on automation and digitalization in industrial processes is also contributing to the market's growth. Belt weighers equipped with advanced features such as real-time data monitoring, remote control, and integration with other industrial systems are gaining popularity. These innovations are helping industries achieve higher levels of efficiency and productivity. Overall, the global Belt Weigher market is poised for steady growth, driven by the increasing demand for precise measurement and control in material handling processes.

| Report Metric | Details |

| Report Name | Belt Weigher Market |

| Accounted market size in 2024 | an estimated US$ 154 million |

| Forecasted market size in 2030 | US$ 173.4 million |

| CAGR | 2.0% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Siemens, Yamato, Schenck, Thermo Scientific, Avery Weigh-Tronix, Merrick, Rice Lake, Convey Weigh, FLSmidth, OJ:S Vagsystem, CST, Thayer Scale, Tecweigh, Saimo, Nanjing Sanai, Henan Fengbo, Sanyuan, SSS Electronics, Shanxi Litry, Baotou Shenda, Changsha Fengye, Shandong Jinzhong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |