What is Global Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) Market?

The Global Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) market is a specialized segment within the electronics manufacturing industry. These systems are designed to separate individual printed circuit boards (PCBs) from a larger panel after the manufacturing process. The depaneling process is crucial because it ensures that the PCBs are not damaged during separation, which can affect their performance and reliability. Automatic depaneling router systems use advanced technology to precisely cut and separate PCBs, reducing the risk of human error and increasing efficiency. These systems are widely used in various industries, including consumer electronics, automotive, medical devices, and aerospace, where high precision and reliability are paramount. The market for these systems is driven by the increasing demand for miniaturized and complex electronic devices, which require more sophisticated manufacturing processes. As technology continues to advance, the need for efficient and reliable depaneling solutions is expected to grow, making this market an essential part of the electronics manufacturing industry.

In-line Automatic Depaneling Router Systems, Off-line Automatic Depaneling Router Systems in the Global Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) Market:

In-line Automatic Depaneling Router Systems and Off-line Automatic Depaneling Router Systems are two primary types of systems used in the Global Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) market. In-line systems are integrated directly into the production line, allowing for continuous and automated depaneling of PCBs as they move through the manufacturing process. These systems are highly efficient and can handle large volumes of PCBs with minimal human intervention. They are ideal for high-volume production environments where speed and consistency are critical. In-line systems often feature advanced automation capabilities, such as robotic arms and vision systems, to ensure precise and accurate depaneling. On the other hand, Off-line Automatic Depaneling Router Systems are standalone units that operate independently of the main production line. These systems are typically used for smaller production runs or for specialized applications where flexibility and customization are required. Off-line systems offer greater control over the depaneling process, allowing operators to adjust settings and parameters to meet specific requirements. They are also easier to set up and reconfigure, making them suitable for environments where production needs frequently change. Both in-line and off-line systems have their advantages and are chosen based on the specific needs of the manufacturing process. In-line systems are preferred for their speed and efficiency, while off-line systems are valued for their flexibility and adaptability. The choice between the two depends on factors such as production volume, complexity of the PCBs, and the level of automation required. As the demand for more sophisticated electronic devices continues to grow, manufacturers are increasingly investing in advanced depaneling solutions to enhance their production capabilities and maintain high-quality standards.

Consumer Electronics, Communications, Industrial and Medical, Automotive, Military and Aerospace, Others in the Global Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) Market:

The usage of Global Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) spans across various industries, each with its unique requirements and challenges. In the consumer electronics industry, these systems are essential for producing high-quality, reliable devices such as smartphones, tablets, and wearable technology. The precision and efficiency of automatic depaneling systems ensure that the delicate components of these devices are not damaged during the manufacturing process, which is crucial for maintaining their performance and longevity. In the communications sector, automatic depaneling systems are used to produce PCBs for networking equipment, telecommunications devices, and other communication infrastructure. The high precision and reliability of these systems are vital for ensuring the performance and durability of communication devices, which are often subjected to harsh operating conditions. In the industrial and medical sectors, automatic depaneling systems are used to manufacture PCBs for a wide range of applications, including industrial automation equipment, medical devices, and diagnostic instruments. The high level of precision and reliability offered by these systems is critical for ensuring the safety and effectiveness of medical devices, which must meet stringent regulatory standards. In the automotive industry, automatic depaneling systems are used to produce PCBs for various electronic components, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). The automotive industry demands high levels of precision and reliability, as electronic components play a crucial role in the safety and performance of vehicles. In the military and aerospace sectors, automatic depaneling systems are used to produce PCBs for mission-critical applications, including avionics, communication systems, and defense equipment. The high precision and reliability of these systems are essential for ensuring the performance and durability of electronic components used in harsh and demanding environments. Other industries that utilize automatic depaneling systems include renewable energy, where they are used to produce PCBs for solar panels and wind turbines, and the IoT (Internet of Things) sector, where they are used to manufacture PCBs for various connected devices. Overall, the versatility and efficiency of automatic depaneling systems make them an indispensable tool in the production of high-quality electronic devices across a wide range of industries.

Global Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) Market Outlook:

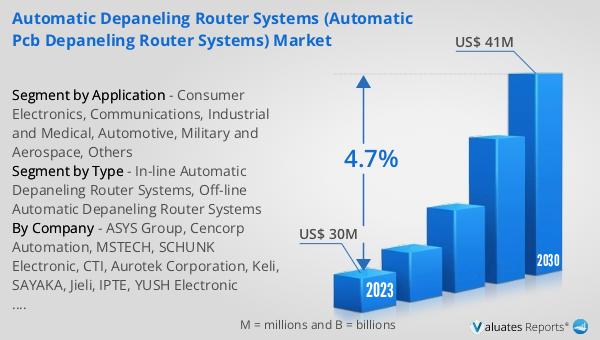

The global market for Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) was valued at $30 million in 2023 and is projected to grow to $41 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.7% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced electronic devices across various industries, including consumer electronics, automotive, medical, and aerospace. The need for high precision and reliability in the manufacturing process is pushing companies to invest in advanced depaneling solutions. These systems not only enhance production efficiency but also ensure the quality and performance of the final products. As technology continues to evolve, the complexity and miniaturization of electronic components are increasing, further driving the demand for sophisticated depaneling systems. The market's growth is also supported by the rising adoption of automation in manufacturing processes, which helps in reducing human error and increasing production speed. With the ongoing advancements in technology and the growing need for high-quality electronic devices, the market for Automatic Depaneling Router Systems is expected to continue its upward trajectory.

| Report Metric | Details |

| Report Name | Automatic Depaneling Router Systems (Automatic PCB Depaneling Router Systems) Market |

| Accounted market size in 2023 | US$ 30 million |

| Forecasted market size in 2030 | US$ 41 million |

| CAGR | 4.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASYS Group, Cencorp Automation, MSTECH, SCHUNK Electronic, CTI, Aurotek Corporation, Keli, SAYAKA, Jieli, IPTE, YUSH Electronic Technology, Genitec, Getech Automation, Osai, Hand in Hand Electronic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |