What is Global Aerospace Polycarbosilanes Market?

The Global Aerospace Polycarbosilanes Market is a specialized segment within the broader aerospace materials industry, focusing on the use of polycarbosilanes. Polycarbosilanes are a type of polymer that contains silicon, carbon, and hydrogen atoms. These materials are particularly valued in the aerospace sector for their ability to be converted into silicon carbide (SiC) fibers, which are known for their high strength, lightweight, and excellent thermal stability. The demand for polycarbosilanes in the aerospace industry is driven by the need for advanced materials that can withstand extreme conditions, such as high temperatures and mechanical stress, while maintaining structural integrity. This market is characterized by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of polycarbosilanes, making them more accessible for various aerospace applications. The global aerospace polycarbosilanes market is a dynamic and evolving field, with significant potential for growth as new technologies and applications continue to emerge.

Liquid Polycarbosilane, Solid Polycarbosilane in the Global Aerospace Polycarbosilanes Market:

Liquid polycarbosilane and solid polycarbosilane are two primary forms of polycarbosilanes used in the global aerospace market. Liquid polycarbosilane is a viscous, fluid-like material that can be easily processed and molded into various shapes. It is often used as a precursor for producing silicon carbide fibers through a process called pyrolysis, where the liquid polycarbosilane is heated to high temperatures in an inert atmosphere, causing it to decompose and form SiC fibers. These fibers are then used to reinforce composite materials, enhancing their mechanical properties and thermal stability. On the other hand, solid polycarbosilane is a more rigid and stable form of the polymer. It is typically used in applications where a solid, durable material is required, such as in the production of fiber-reinforced silicon carbide composites. These composites are made by embedding SiC fibers into a solid polycarbosilane matrix, creating a material that combines the strength and heat resistance of SiC fibers with the structural integrity of the polycarbosilane matrix. Both liquid and solid polycarbosilanes play crucial roles in the aerospace industry, offering unique advantages depending on the specific requirements of the application. The choice between liquid and solid polycarbosilane depends on factors such as the desired properties of the final product, the manufacturing process, and the specific performance criteria needed for the aerospace component.

Silicon Carbide Fiber, Fiber Reinforced Silicon Carbide Composites, Coating, Other in the Global Aerospace Polycarbosilanes Market:

The usage of polycarbosilanes in the global aerospace market spans several key areas, including silicon carbide fiber, fiber-reinforced silicon carbide composites, coatings, and other specialized applications. Silicon carbide fiber, derived from polycarbosilanes, is highly valued for its exceptional strength-to-weight ratio and thermal stability. These fibers are used to reinforce composite materials, making them ideal for high-performance aerospace components that must endure extreme conditions. Fiber-reinforced silicon carbide composites, which combine SiC fibers with a polycarbosilane matrix, offer enhanced mechanical properties and resistance to thermal and chemical degradation. These composites are used in critical aerospace applications such as turbine blades, heat shields, and structural components, where durability and performance are paramount. Polycarbosilanes are also used in coatings to provide protective layers that enhance the thermal and oxidative stability of aerospace materials. These coatings help to extend the lifespan of components by protecting them from harsh environmental conditions, such as high temperatures and corrosive atmospheres. Additionally, polycarbosilanes find applications in other specialized areas, such as the production of ceramic matrix composites and advanced ceramics, which are used in various aerospace systems and components. The versatility and high-performance characteristics of polycarbosilanes make them indispensable in the aerospace industry, driving ongoing research and development efforts to further expand their applications and improve their properties.

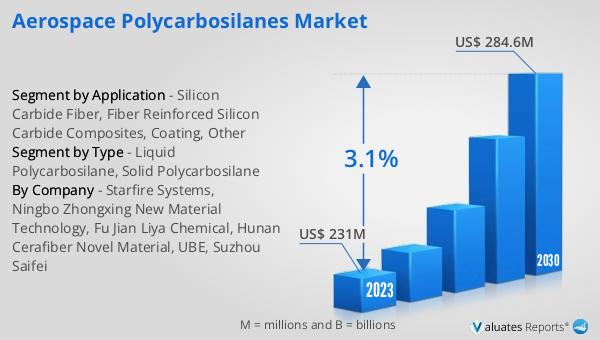

Global Aerospace Polycarbosilanes Market Outlook:

The global aerospace polycarbosilanes market was valued at approximately $231 million in 2023 and is projected to grow to around $284.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced materials in the aerospace industry, driven by the need for lightweight, high-strength, and thermally stable components. The market's expansion is supported by continuous advancements in polycarbosilane technology and the development of new applications that leverage the unique properties of these materials. As the aerospace industry continues to evolve, the demand for polycarbosilanes is expected to rise, driven by their critical role in enhancing the performance and durability of aerospace components. The projected growth of the global aerospace polycarbosilanes market underscores the importance of these materials in meeting the stringent requirements of modern aerospace applications, ensuring the continued development and adoption of innovative solutions in the industry.

| Report Metric | Details |

| Report Name | Aerospace Polycarbosilanes Market |

| Accounted market size in 2023 | US$ 231 million |

| Forecasted market size in 2030 | US$ 284.6 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Starfire Systems, Ningbo Zhongxing New Material Technology, Fu Jian Liya Chemical, Hunan Cerafiber Novel Material, UBE, Suzhou Saifei |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |