What is Global ESD Blister Tray Market?

The Global ESD Blister Tray Market refers to the worldwide industry focused on the production and distribution of electrostatic discharge (ESD) blister trays. These trays are specifically designed to protect sensitive electronic components from static electricity, which can cause significant damage during manufacturing, transportation, and storage. ESD blister trays are made from materials that dissipate static charges, ensuring the safety and integrity of electronic parts. The market encompasses various types of ESD blister trays, catering to different industries such as electronics, pharmaceuticals, food, and industrial sectors. The demand for these trays is driven by the increasing need for safe and reliable packaging solutions that prevent static damage, thereby ensuring the quality and functionality of sensitive products. As technology advances and the use of electronic components grows, the Global ESD Blister Tray Market is expected to expand, offering innovative solutions to meet the evolving needs of various industries.

PP Anti-Static Blister Tray, PET Anti-Static Blister Tray, HIPS Anti-Static Blister Tray, Others in the Global ESD Blister Tray Market:

PP Anti-Static Blister Trays, PET Anti-Static Blister Trays, HIPS Anti-Static Blister Trays, and other types of trays play a crucial role in the Global ESD Blister Tray Market. PP (Polypropylene) Anti-Static Blister Trays are known for their durability, chemical resistance, and ability to withstand high temperatures. These trays are commonly used in industries where robust and long-lasting packaging is required. PET (Polyethylene Terephthalate) Anti-Static Blister Trays, on the other hand, are valued for their clarity, strength, and recyclability. They are often used in applications where visibility of the product is important, such as in retail packaging. HIPS (High Impact Polystyrene) Anti-Static Blister Trays offer a balance of strength and flexibility, making them suitable for a wide range of applications. These trays are particularly popular in the electronics industry due to their excellent impact resistance and ease of fabrication. Other types of ESD blister trays include those made from materials like PVC (Polyvinyl Chloride) and ABS (Acrylonitrile Butadiene Styrene), each offering unique properties tailored to specific needs. PVC trays are known for their excellent chemical resistance and durability, while ABS trays provide superior impact resistance and toughness. The choice of material depends on the specific requirements of the application, such as the level of static protection needed, the environmental conditions, and the nature of the products being packaged. The versatility and adaptability of these different types of ESD blister trays make them indispensable in various industries, ensuring the safe handling and transportation of sensitive electronic components and other products.

Electronic Field, Industrial Field, Pharmaceutical Field, Food Field, Others in the Global ESD Blister Tray Market:

The usage of Global ESD Blister Tray Market spans across several key areas, including the electronic field, industrial field, pharmaceutical field, food field, and others. In the electronic field, ESD blister trays are essential for protecting delicate electronic components such as semiconductors, circuit boards, and microchips from static discharge. These trays ensure that the components remain free from damage during manufacturing, assembly, and transportation, thereby maintaining their functionality and reliability. In the industrial field, ESD blister trays are used to safeguard sensitive equipment and tools that are prone to static damage. This includes precision instruments, sensors, and other high-value items that require careful handling. The pharmaceutical field also benefits from ESD blister trays, particularly in the packaging of sensitive medical devices and diagnostic equipment. These trays help maintain the sterility and integrity of the products, ensuring they reach the end-users in optimal condition. In the food field, ESD blister trays are used for packaging items that are sensitive to static electricity, such as certain types of confectionery and snack foods. These trays help prevent contamination and preserve the quality of the food products. Additionally, ESD blister trays find applications in other areas such as automotive, aerospace, and consumer goods, where the protection of sensitive components from static discharge is crucial. The versatility and effectiveness of ESD blister trays make them a valuable asset in ensuring the safety and quality of products across various industries.

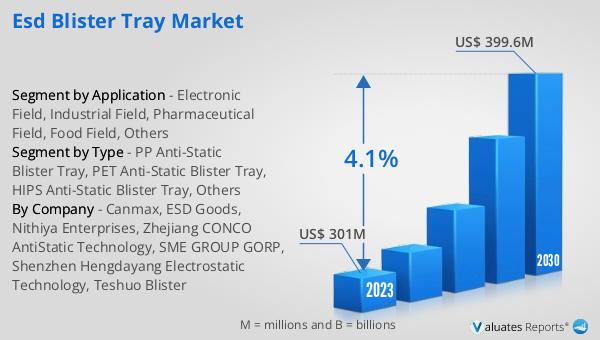

Global ESD Blister Tray Market Outlook:

The global ESD Blister Tray market was valued at US$ 301 million in 2023 and is anticipated to reach US$ 399.6 million by 2030, witnessing a CAGR of 4.1% during the forecast period 2024-2030. This growth reflects the increasing demand for reliable and effective packaging solutions that protect sensitive electronic components from static discharge. As industries continue to advance and the use of electronic devices becomes more widespread, the need for ESD blister trays is expected to rise. These trays play a critical role in ensuring the safety and functionality of electronic parts, making them an essential component in various sectors. The market's expansion is driven by the continuous innovation and development of new materials and designs that enhance the performance and versatility of ESD blister trays. With the growing emphasis on quality and reliability, the Global ESD Blister Tray Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | ESD Blister Tray Market |

| Accounted market size in 2023 | US$ 301 million |

| Forecasted market size in 2030 | US$ 399.6 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Canmax, ESD Goods, Nithiya Enterprises, Zhejiang CONCO AntiStatic Technology, SME GROUP GORP, Shenzhen Hengdayang Electrostatic Technology, Teshuo Blister |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |