What is Global Aluminum for Electric Vehicles Market?

The Global Aluminum for Electric Vehicles Market refers to the worldwide industry focused on the production and utilization of aluminum specifically for electric vehicles (EVs). Aluminum is a lightweight, durable, and highly recyclable material, making it an ideal choice for EV manufacturers looking to improve vehicle efficiency and reduce overall weight. This market encompasses various types of aluminum products, including cast aluminum, rolled aluminum, and extruded aluminum, each serving different purposes within the EV manufacturing process. The demand for aluminum in EVs is driven by the need to enhance vehicle performance, increase battery range, and meet stringent environmental regulations. As the adoption of electric vehicles continues to grow globally, the market for aluminum in this sector is expected to expand significantly, driven by advancements in technology and increasing consumer awareness of sustainable transportation options.

Cast Aluminum, Rolled Aluminum, Extruded Aluminum, Others in the Global Aluminum for Electric Vehicles Market:

Cast aluminum, rolled aluminum, extruded aluminum, and other forms of aluminum play crucial roles in the Global Aluminum for Electric Vehicles Market. Cast aluminum is produced by pouring molten aluminum into a mold, where it solidifies into a specific shape. This type of aluminum is commonly used in the manufacturing of complex and intricate components such as engine blocks, transmission cases, and other structural parts. Its high strength-to-weight ratio and excellent thermal conductivity make it ideal for applications that require durability and heat dissipation. Rolled aluminum, on the other hand, is created by passing aluminum ingots through a series of rollers to achieve the desired thickness and shape. This process results in aluminum sheets, plates, and foils that are used in various parts of an electric vehicle, including body panels, heat shields, and battery enclosures. Rolled aluminum is valued for its lightweight properties, corrosion resistance, and ability to be easily formed into different shapes. Extruded aluminum is produced by forcing aluminum through a die to create long, continuous shapes with a consistent cross-section. This type of aluminum is used in the production of structural components such as chassis, suspension parts, and battery trays. Extruded aluminum offers high strength, flexibility, and excellent machinability, making it suitable for applications that require precise dimensions and complex geometries. Other forms of aluminum, such as aluminum alloys and composites, are also used in the EV market to enhance specific properties like strength, conductivity, and resistance to wear and tear. These materials are often used in specialized applications such as electrical wiring, connectors, and thermal management systems. Overall, the diverse range of aluminum products available in the market allows EV manufacturers to optimize vehicle performance, reduce weight, and improve energy efficiency, contributing to the overall growth and development of the Global Aluminum for Electric Vehicles Market.

Powertrain, Chassis & Suspension, Car Body in the Global Aluminum for Electric Vehicles Market:

The usage of aluminum in electric vehicles spans several critical areas, including the powertrain, chassis and suspension, and car body. In the powertrain, aluminum is used to manufacture components such as electric motor housings, battery enclosures, and power electronics casings. The lightweight nature of aluminum helps reduce the overall weight of the powertrain, which in turn improves the vehicle's efficiency and extends its driving range. Additionally, aluminum's excellent thermal conductivity aids in the effective dissipation of heat generated by the electric motor and battery, ensuring optimal performance and longevity of these critical components. In the chassis and suspension, aluminum is used to produce parts such as control arms, subframes, and shock towers. The use of aluminum in these areas helps reduce the unsprung weight of the vehicle, leading to improved handling, ride comfort, and overall driving dynamics. Aluminum's high strength-to-weight ratio also enhances the structural integrity of the chassis, providing better crash protection and safety for occupants. In the car body, aluminum is used to manufacture body panels, doors, hoods, and trunk lids. The lightweight properties of aluminum contribute to a significant reduction in the overall weight of the vehicle, which directly impacts its energy efficiency and performance. Aluminum body panels also offer excellent corrosion resistance, ensuring the longevity and durability of the vehicle's exterior. Furthermore, the use of aluminum in the car body allows for greater design flexibility, enabling manufacturers to create sleek and aerodynamic shapes that enhance the vehicle's aesthetics and reduce drag. Overall, the extensive use of aluminum in electric vehicles across these critical areas plays a vital role in improving vehicle performance, efficiency, and safety, making it a key material in the development of sustainable transportation solutions.

Global Aluminum for Electric Vehicles Market Outlook:

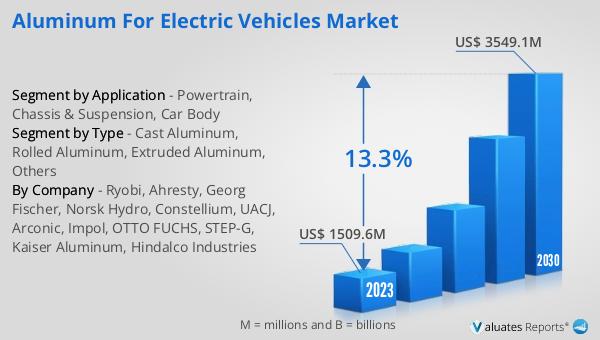

The global Aluminum for Electric Vehicles market was valued at US$ 1509.6 million in 2023 and is anticipated to reach US$ 3549.1 million by 2030, witnessing a CAGR of 13.3% during the forecast period 2024-2030. This significant growth reflects the increasing demand for lightweight and efficient materials in the production of electric vehicles. As the automotive industry continues to shift towards electrification, the need for materials that can enhance vehicle performance, extend battery range, and meet stringent environmental regulations becomes more critical. Aluminum, with its lightweight, durable, and recyclable properties, is well-positioned to meet these demands. The projected growth in the market indicates a strong trend towards the adoption of aluminum in various components of electric vehicles, driven by advancements in technology and increasing consumer awareness of sustainable transportation options. This growth also highlights the importance of continued innovation and investment in the development of new aluminum products and manufacturing processes to support the evolving needs of the electric vehicle industry.

| Report Metric | Details |

| Report Name | Aluminum for Electric Vehicles Market |

| Accounted market size in 2023 | US$ 1509.6 million |

| Forecasted market size in 2030 | US$ 3549.1 million |

| CAGR | 13.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ryobi, Ahresty, Georg Fischer, Norsk Hydro, Constellium, UACJ, Arconic, Impol, OTTO FUCHS, STEP-G, Kaiser Aluminum, Hindalco Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |