What is Global Alloy Cutting Fluid Market?

The Global Alloy Cutting Fluid Market refers to the worldwide industry focused on the production, distribution, and utilization of cutting fluids specifically designed for alloy materials. Cutting fluids, also known as coolants or lubricants, are essential in machining processes to reduce heat and friction between the cutting tool and the workpiece. These fluids enhance the lifespan of cutting tools, improve surface finish, and increase the efficiency of the machining process. The market encompasses various types of cutting fluids, including oil-based, water-based, and synthetic fluids, each tailored to specific machining needs and alloy types. The demand for alloy cutting fluids is driven by industries such as aerospace, automotive, military, and transportation, where precision and durability are paramount. As these industries continue to grow and evolve, the need for advanced cutting fluids that can handle high-performance alloys becomes increasingly critical. The market is characterized by continuous innovation, with manufacturers developing new formulations to meet the stringent requirements of modern machining applications.

Oil-based, Water-based in the Global Alloy Cutting Fluid Market:

Oil-based and water-based cutting fluids are two primary categories within the Global Alloy Cutting Fluid Market, each offering distinct advantages and applications. Oil-based cutting fluids are typically composed of mineral oils or synthetic oils, often enhanced with additives to improve their performance. These fluids provide excellent lubrication, reducing friction and wear on cutting tools, which is particularly beneficial when machining tough alloys. The high lubricity of oil-based fluids helps in achieving smoother finishes and extending tool life. However, they can be more challenging to manage in terms of disposal and environmental impact, as they are not as easily biodegradable as water-based fluids. On the other hand, water-based cutting fluids, also known as water-soluble or emulsifiable oils, are composed of water mixed with oils and additives. These fluids offer superior cooling properties due to the high thermal conductivity of water, making them ideal for high-speed machining operations where heat dissipation is crucial. Water-based fluids are generally more environmentally friendly and easier to clean up, as they can be diluted and washed away with water. They also tend to be less expensive than oil-based fluids. However, they may not provide the same level of lubrication as oil-based fluids, which can be a drawback in certain applications. The choice between oil-based and water-based cutting fluids depends on various factors, including the type of alloy being machined, the specific machining process, and environmental considerations. In the aerospace industry, where precision and surface finish are critical, oil-based fluids are often preferred for their superior lubricating properties. In contrast, water-based fluids are commonly used in high-speed machining operations in the automotive and transportation sectors, where efficient cooling is essential. Both types of fluids are continually being improved with advanced additives and formulations to enhance their performance and address specific machining challenges. As the Global Alloy Cutting Fluid Market evolves, the development of cutting fluids that balance lubrication, cooling, environmental impact, and cost will remain a key focus for manufacturers and end-users alike.

Aerospace Industry, Military Field, Transportation in the Global Alloy Cutting Fluid Market:

The usage of Global Alloy Cutting Fluid Market in the aerospace industry, military field, and transportation sector is extensive and multifaceted. In the aerospace industry, cutting fluids are crucial for machining high-performance alloys used in aircraft components. These alloys, such as titanium and nickel-based superalloys, are known for their strength and resistance to high temperatures, but they are also challenging to machine. Cutting fluids help in reducing the heat generated during machining, preventing thermal damage to both the workpiece and the cutting tool. They also improve the surface finish and dimensional accuracy of the machined parts, which is vital for aerospace applications where precision is paramount. In the military field, cutting fluids are used in the manufacturing of various defense equipment and components. The military often requires materials that can withstand extreme conditions, such as high-strength alloys and composites. Cutting fluids play a critical role in machining these materials, ensuring that the components meet stringent quality and performance standards. They help in extending the life of cutting tools, reducing downtime, and increasing the overall efficiency of the manufacturing process. In the transportation sector, cutting fluids are used in the production of automotive and railway components. The automotive industry, in particular, relies on cutting fluids for machining engine parts, transmission components, and other critical parts made from various alloys. These fluids help in achieving the desired surface finish and dimensional accuracy, which are essential for the performance and reliability of the vehicles. In the railway industry, cutting fluids are used in the manufacturing of tracks, wheels, and other components that require high precision and durability. Overall, the Global Alloy Cutting Fluid Market plays a vital role in these industries by enhancing the machining process, improving the quality of the finished products, and contributing to the overall efficiency and productivity of the manufacturing operations.

Global Alloy Cutting Fluid Market Outlook:

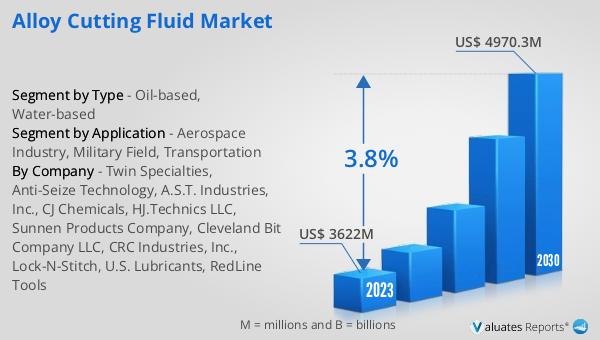

The global Alloy Cutting Fluid market was valued at US$ 3622 million in 2023 and is anticipated to reach US$ 4970.3 million by 2030, witnessing a CAGR of 3.8% during the forecast period 2024-2030. This market growth reflects the increasing demand for high-performance cutting fluids that can meet the stringent requirements of modern machining applications. The aerospace, automotive, military, and transportation sectors are major drivers of this demand, as they require cutting fluids that can handle advanced alloys and deliver superior performance. The market is characterized by continuous innovation, with manufacturers developing new formulations to enhance the lubricating and cooling properties of cutting fluids. Environmental considerations are also playing a significant role, with a growing emphasis on developing cutting fluids that are biodegradable and less harmful to the environment. As industries continue to evolve and adopt new technologies, the demand for advanced cutting fluids is expected to rise, driving the growth of the Global Alloy Cutting Fluid Market.

| Report Metric | Details |

| Report Name | Alloy Cutting Fluid Market |

| Accounted market size in 2023 | US$ 3622 million |

| Forecasted market size in 2030 | US$ 4970.3 million |

| CAGR | 3.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Twin Specialties, Anti-Seize Technology, A.S.T. Industries, Inc., CJ Chemicals, HJ.Technics LLC, Sunnen Products Company, Cleveland Bit Company LLC, CRC Industries, Inc., Lock-N-Stitch, U.S. Lubricants, RedLine Tools |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |