What is Oil-free Venturi Ejector - Global Market?

The Oil-free Venturi Ejector market is a fascinating sector that's gaining traction globally due to its unique offering of pollution-free operation in various industrial processes. Essentially, an Oil-free Venturi Ejector is a device that employs a jet of fluid or gas to create a vacuum without the need for moving parts or oil lubrication. This technology leverages the Venturi effect, where fluid speed increases while pressure decreases as it passes through a constricted section of a tube. The absence of oil not only reduces the risk of contamination in sensitive environments but also minimizes maintenance requirements and operational costs. Given its eco-friendly and efficient nature, the global market for Oil-free Venturi Ejectors is witnessing a growing demand across diverse sectors. As industries worldwide push for greener and more sustainable practices, the adoption of such oil-free technologies is expected to rise, reflecting a broader shift towards environmentally responsible manufacturing and processing methods.

Single Stage, Multi-stage in the Oil-free Venturi Ejector - Global Market:

Diving deep into the Oil-free Venturi Ejector global market, it's essential to understand its segmentation into Single Stage and Multi-stage ejectors, each catering to distinct operational needs and efficiency levels. Single Stage Oil-free Venturi Ejectors are typically used for applications requiring moderate vacuum levels with high flow rates, making them ideal for quick evacuations or processes where a precise vacuum level isn't critical. On the other hand, Multi-stage Oil-free Venturi Ejectors, which consist of several ejector stages in series, are designed for applications demanding deeper vacuum levels. By sequentially lowering the pressure, these multi-stage systems can achieve significantly higher vacuum levels than their single-stage counterparts, albeit with lower flow rates. This makes them suitable for more demanding industrial applications where a deep vacuum is essential. The global market for these ejectors is expanding as industries seek more efficient, reliable, and cleaner vacuum solutions to meet stringent environmental regulations and operational efficiency goals. The versatility of Single and Multi-stage Oil-free Venturi Ejectors, combined with their operational benefits, positions them as key components in the future of industrial vacuum and pneumatic systems worldwide.

Chemical, Industrial, Food, Medical in the Oil-free Venturi Ejector - Global Market:

The usage of Oil-free Venturi Ejectors in the global market spans across several critical sectors, including Chemical, Industrial, Food, and Medical, each benefiting uniquely from this technology. In the Chemical sector, the need for contamination-free processes is paramount; Oil-free Venturi Ejectors eliminate the risk of oil vapor contamination, ensuring the purity of chemical products. Industrial applications, on the other hand, value the reliability and low maintenance of these ejectors, as they can operate in harsh environments without the need for lubrication, reducing downtime and operational costs. The Food industry benefits from the use of Oil-free Venturi Ejectors in packaging and processing, where maintaining the integrity and safety of food products is essential. The absence of oil eliminates the risk of contamination, meeting the stringent hygiene standards required in food production. Lastly, the Medical sector utilizes these ejectors in various applications, including dental suction systems and surgical vacuum systems, where the highest levels of cleanliness and safety are necessary. The adaptability and environmental benefits of Oil-free Venturi Ejectors make them indispensable in these sectors, driving their global market demand as industries continue to prioritize sustainability and efficiency.

Oil-free Venturi Ejector - Global Market Outlook:

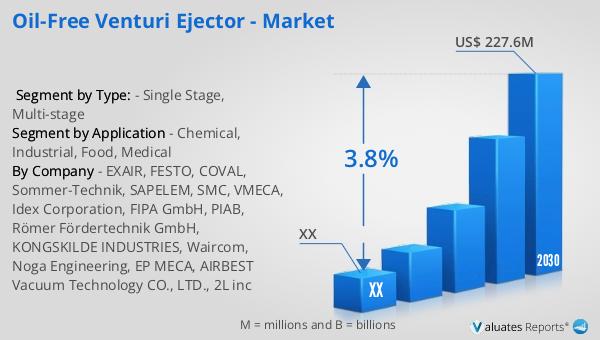

The market outlook for the Oil-free Venturi Ejector sector presents a promising future, with projections indicating a growth from a valuation of US$ 176 million in 2023 to an anticipated US$ 227.6 million by 2030, marking a Compound Annual Growth Rate (CAGR) of 3.8% throughout the forecast period from 2024 to 2030. This growth trajectory underscores the increasing adoption and reliance on Oil-free Venturi Ejector technology across various industries seeking efficient, environmentally friendly vacuum solutions. Specifically, the North American market, a significant contributor to this sector's expansion, is expected to witness substantial growth, reflecting the region's stringent environmental regulations and the industries' shift towards sustainable manufacturing practices. The forecasted growth rates highlight the sector's potential and the growing recognition of Oil-free Venturi Ejectors as a critical component in modern industrial applications, driven by the demand for cleaner, more efficient, and reliable vacuum and pneumatic systems. This optimistic market outlook is a testament to the technology's benefits and its alignment with global trends towards sustainability and operational efficiency.

| Report Metric | Details |

| Report Name | Oil-free Venturi Ejector - Market |

| Forecasted market size in 2030 | US$ 227.6 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | EXAIR, FESTO, COVAL, Sommer-Technik, SAPELEM, SMC, VMECA, Idex Corporation, FIPA GmbH, PIAB, Römer Fördertechnik GmbH, KONGSKILDE INDUSTRIES, Waircom, Noga Engineering, EP MECA, AIRBEST Vacuum Technology CO., LTD., 2L inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |