What is Global Sintering-type Conductive Paste Market?

The Global Sintering-type Conductive Paste Market is an intriguing sector that focuses on the production and distribution of specialized pastes used in various electronic and electrical applications. These pastes are essential for creating conductive pathways in electronic components, enabling them to function efficiently. The sintering process, which involves compacting and forming materials using heat without melting them to the point of liquefaction, plays a crucial role in the manufacturing of these pastes. This process ensures that the conductive particles within the paste are bonded tightly together, enhancing the electrical conductivity of the final product. The market for these sintering-type conductive pastes is driven by the increasing demand for more efficient and reliable electronic devices across multiple industries. As technology advances, the need for components that can withstand higher temperatures and provide superior electrical conductivity continues to rise, making the role of sintering-type conductive pastes more vital than ever. This market encompasses a variety of paste types, including those made with silver, aluminum, and other materials, each offering distinct properties and advantages for specific applications.

Sintered Silver Paste, Sintered Aluminum Paste, Others in the Global Sintering-type Conductive Paste Market:

Diving deeper into the Global Sintering-type Conductive Paste Market, we find it segmented into several key products: Sintered Silver Paste, Sintered Aluminum Paste, and others. Sintered Silver Paste is highly sought after for its exceptional electrical conductivity and thermal conductivity, making it an ideal choice for high-performance applications in the semiconductor and photovoltaic sectors. This paste is particularly valuable in environments where electrical efficiency and durability are paramount. On the other hand, Sintered Aluminum Paste is favored for its cost-effectiveness and good electrical conductivity, often used in the automotive and consumer electronics industries where balancing performance with cost is crucial. Other types of sintering-type conductive pastes, including those made with different metals or metal alloys, cater to a wide range of specialized applications, offering tailored properties such as flexibility, resistance to oxidation, and compatibility with various substrates. The diversity within this market underscores the versatility and adaptability of sintering-type conductive pastes to meet the evolving needs of technology manufacturers. With ongoing research and development, the formulations and applications of these pastes continue to expand, driving innovation in electronic device manufacturing and beyond.

IT Equipment, Automobile Electric, Household Electric, Others in the Global Sintering-type Conductive Paste Market:

The usage of the Global Sintering-type Conductive Paste Market spans across several critical sectors, including IT Equipment, Automobile Electric, Household Electric, and others, showcasing its versatility and essential role in modern technology. In IT Equipment, these conductive pastes are used to ensure the reliable operation of devices such as computers, servers, and mobile phones, where efficient electrical conductivity is crucial for performance and durability. The automobile sector benefits from these pastes in electric vehicles and electronic components, where they contribute to the safety and functionality of various systems, including battery connections and sensor units. Household electric applications, including appliances and lighting systems, rely on these pastes for their electrical connections, ensuring energy efficiency and longevity. Other areas of application include aerospace, medical devices, and renewable energy systems, where the unique properties of sintering-type conductive pastes, such as resistance to high temperatures and environmental conditions, are particularly valuable. This wide-ranging applicability underscores the importance of these pastes in advancing and maintaining the performance of electronic and electrical systems across industries.

Global Sintering-type Conductive Paste Market Outlook:

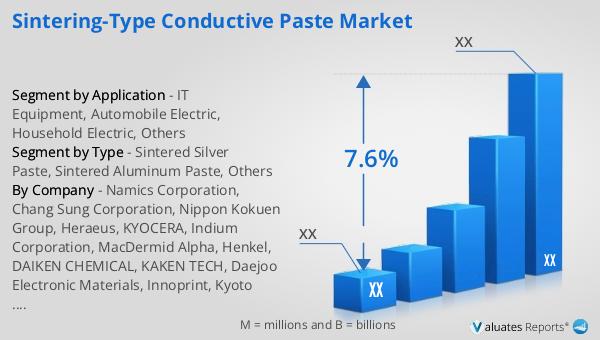

The market outlook for the Global Conductive Paste Market is set for significant growth, with expectations to expand from a valuation of USD 2.07 billion in 2020 to an anticipated figure by 2028, marking a Compound Annual Growth Rate (CAGR) of 7.6% during the period from 2021 to 2028. This projection underscores the increasing reliance on and demand for conductive pastes across various sectors, driven by the continuous advancement in electronic and electrical device manufacturing. The growth trajectory of this market reflects the critical role that these pastes play in enhancing the performance, efficiency, and reliability of electronic components and systems. As industries worldwide strive for innovation and higher standards in electronic functionalities, the demand for sintering-type conductive pastes, known for their superior electrical conductivity and thermal properties, is expected to surge. This market expansion is indicative of the broader trends in technology development, including the push for more sustainable and efficient electronic solutions, which these conductive pastes are poised to support.

| Report Metric | Details |

| Report Name | Sintering-type Conductive Paste Market |

| CAGR | 7.6% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Namics Corporation, Chang Sung Corporation, Nippon Kokuen Group, Heraeus, KYOCERA, Indium Corporation, MacDermid Alpha, Henkel, DAIKEN CHEMICAL, KAKEN TECH, Daejoo Electronic Materials, Innoprint, Kyoto Elex, Dongguan City Betterly New Materials, DuPont, Pilotm New Materials, Mitsuboshi Belting, Advanced Electronic Materials Inc, Hunan LEED Electronic Ink, Advanced Joining, Shenzhen Facemoore Technology, NANO TOP, Tanaka Kikinzoku, Solderwell Advanced Materials, Nihon Superior, Nihon Handa, NBE Tech, Guangzhou Xianyi Electronic Technology, Bando Chemical Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |