What is Global Powder Metallurgy Machinery Parts Market?

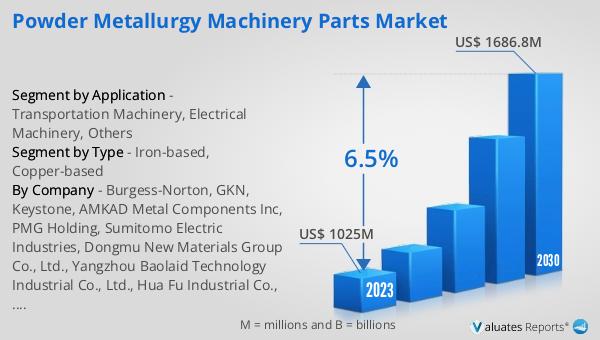

The Global Powder Metallurgy Machinery Parts Market is a fascinating sector that delves into the production of machinery parts through the process of powder metallurgy. This innovative method involves the compaction of powdered metals and alloys into desired shapes, followed by heating (sintering) to solidify the parts without melting them completely. This technique allows for the creation of complex and precise components that are increasingly sought after in various industries due to their superior qualities, such as high tolerance levels, excellent finish, and material efficiency. The market for these parts is significant, as it caters to a wide range of applications from automotive to aerospace, and even in the production of household appliances. As of 2023, the market's value stood impressively at US$ 1025 million, showcasing the vast demand and reliance on this technology. With a projected growth rate, it's expected to soar to US$ 1686.8 million by 2030. This growth is attributed to the continuous advancements in powder metallurgy techniques and the expanding range of metals and alloys that can be processed, making it a pivotal area in the manufacturing sector.

Iron-based, Copper-based in the Global Powder Metallurgy Machinery Parts Market:

Diving into the specifics, the Global Powder Metallurgy Machinery Parts Market is segmented into iron-based and copper-based parts, each serving unique purposes across various industries. Iron-based components are renowned for their strength and durability, making them ideal for high-stress applications such as automotive engines and machinery. These parts benefit from the inherent properties of iron, including its wear resistance and ability to withstand high temperatures, which are enhanced through the powder metallurgy process. On the other hand, copper-based parts are celebrated for their excellent thermal and electrical conductivity, making them indispensable in electrical machinery and components. The versatility of copper allows for the creation of parts that not only conduct electricity efficiently but also exhibit superior corrosion resistance and strength. The production of both iron and copper-based parts through powder metallurgy offers significant advantages over traditional manufacturing methods, including material conservation, reduced energy consumption, and the ability to produce complex shapes with minimal waste. This segment of the market is crucial for the development of components in sectors ranging from automotive to electronics, highlighting the diverse applications and importance of powder metallurgy machinery parts in modern manufacturing.

Transportation Machinery, Electrical Machinery, Others in the Global Powder Metallurgy Machinery Parts Market:

The usage of Global Powder Metallurgy Machinery Parts in areas such as transportation machinery, electrical machinery, and others, showcases the versatility and essential role of this market in various sectors. In transportation machinery, powder metallurgy parts are crucial for manufacturing components that require high precision and durability, such as gears, bearings, and sprockets. These parts contribute to the efficiency and reliability of vehicles, from cars to airplanes, by ensuring that they operate smoothly under different conditions. Similarly, in electrical machinery, the use of copper-based powder metallurgy parts is pivotal due to their superior electrical conductivity. Components like connectors, switches, and relays made through this process are integral to the performance and longevity of electrical devices. Beyond these, the "others" category encompasses a wide range of applications, including household appliances, medical devices, and industrial machinery, where powder metallurgy parts are valued for their precision, strength, and material properties. The adaptability of powder metallurgy to produce parts that meet specific requirements across these diverse fields underscores its significance in advancing technology and improving the functionality and efficiency of various machinery and equipment.

Global Powder Metallurgy Machinery Parts Market Outlook:

Regarding the market outlook for the Global Powder Metallurgy Machinery Parts Market, it's noteworthy to mention that the sector has shown a robust valuation of US$ 1025 million as of 2023. This figure is not just a testament to the current demand but also sets the stage for future growth, with projections indicating a potential increase to US$ 1686.8 million by the year 2030. This anticipated growth, marked by a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030, reflects the expanding applications and technological advancements within the powder metallurgy field. The increasing adoption of powder metallurgy parts across various industries, driven by their benefits such as reduced waste, energy efficiency, and the ability to produce complex shapes, underscores the market's potential for substantial growth. This outlook highlights the market's dynamic nature and its critical role in shaping the future of manufacturing and industrial processes.

| Report Metric | Details |

| Report Name | Powder Metallurgy Machinery Parts Market |

| Accounted market size in 2023 | US$ 1025 million |

| Forecasted market size in 2030 | US$ 1686.8 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Burgess-Norton, GKN, Keystone, AMKAD Metal Components Inc, PMG Holding, Sumitomo Electric Industries, Dongmu New Materials Group Co., Ltd., Yangzhou Baolaid Technology Industrial Co., Ltd., Hua Fu Industrial Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |