What is Global Industrial Tension Controllers Market?

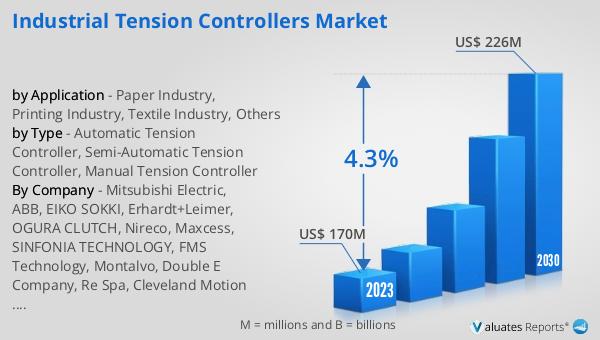

The Global Industrial Tension Controllers Market is a specialized sector that focuses on devices designed to control tension in various materials during their processing. These controllers are pivotal in industries where materials like paper, textiles, and metals are processed, ensuring that the tension is maintained at an optimal level to guarantee quality and efficiency in production. The market encompasses devices that cater to different levels of automation and precision, including manual, semi-automatic, and fully automatic tension controllers. Each type serves a unique purpose, catering to the varying needs of industrial operations. The importance of these controllers stems from their ability to significantly reduce waste and improve product quality, making them a crucial component in the manufacturing process. As industries strive for higher efficiency and lower operational costs, the demand for advanced tension controllers is expected to rise, reflecting the market's growth potential. With a valuation of US$ 170 million in 2023, the market is projected to expand to US$ 226 million by 2030, marking a steady growth rate. This growth is indicative of the increasing reliance on sophisticated machinery to meet the demands of modern manufacturing and processing industries.

Automatic Tension Controller, Semi-Automatic Tension Controller, Manual Tension Controller in the Global Industrial Tension Controllers Market:

Diving into the specifics of the Global Industrial Tension Controllers Market, we find a diverse range of products including Automatic Tension Controllers, Semi-Automatic Tension Controllers, and Manual Tension Controllers. Automatic Tension Controllers are the pinnacle of innovation in this market, offering precision and ease of use that is unparalleled. They automatically adjust the tension of the material being processed using sophisticated sensors and algorithms, ensuring optimal tension at all times without the need for manual intervention. This is particularly beneficial in high-speed production environments where manual adjustments are impractical. On the other hand, Semi-Automatic Tension Controllers strike a balance between automation and manual control. They allow for initial settings to be applied automatically, with the option for manual adjustments as needed. This flexibility makes them suitable for a wide range of applications, providing a cost-effective solution that still offers a degree of automation. Manual Tension Controllers, while being the most basic among the three, play a crucial role in applications where precision and control are paramount. They require operators to adjust tension manually, offering the highest level of control. This type of controller is often used in specialized applications where the material being processed is delicate or the desired tension is difficult to maintain automatically. Each of these controller types has its own set of advantages and applications, making the Global Industrial Tension Controllers Market a diverse and dynamic field.

Paper Industry, Printing Industry, Textile Industry, Others in the Global Industrial Tension Controllers Market:

The Global Industrial Tension Controllers Market finds its applications spread across various industries, each with its unique requirements and challenges. In the Paper Industry, tension controllers are essential for maintaining the correct tension on paper webs to prevent tears and ensure uniform thickness across large rolls. This is crucial for the production of high-quality paper products. The Printing Industry, similarly, relies heavily on tension controllers to manage the tension of paper or other substrates during the printing process. Precise tension control is vital to avoid misalignment and ensure that prints are clear and accurate. In the Textile Industry, tension controllers play a pivotal role in ensuring that yarns and fabrics are kept at the correct tension during weaving, knitting, or other processes. This is important not only for the quality of the final product but also for the efficiency of the production process, as improper tension can lead to material wastage and machine downtime. Other industries, including packaging, electronics, and metalworking, also benefit from the use of tension controllers. These devices ensure that materials are handled gently yet firmly, preventing damage while maintaining productivity. The versatility and adaptability of tension controllers to different materials and processes underscore their importance in modern industrial operations, highlighting the diverse applications of the Global Industrial Tension Controllers Market.

Global Industrial Tension Controllers Market Outlook:

Regarding the market outlook for the Global Industrial Tension Controllers Market, it's observed that the sector started with a valuation of US$ 170 million in 2023. This figure is expected to climb to US$ 226 million by the year 2030. This growth trajectory, marked by a Compound Annual Growth Rate (CAGR) of 4.3% during the forecast period from 2024 to 2030, illustrates a robust and expanding market. This expansion reflects the increasing adoption of tension control technologies across various industries aiming to enhance production efficiency and product quality. The steady growth rate is indicative of the market's response to the rising demand for precision in manufacturing processes and the ongoing technological advancements in tension control systems. As industries continue to evolve and seek out more efficient and reliable production methods, the importance of tension controllers in ensuring material integrity and process stability cannot be overstated. This market outlook underscores the critical role that these controllers play in modern industrial operations and their contribution to the broader goals of innovation and efficiency in manufacturing.

| Report Metric | Details |

| Report Name | Industrial Tension Controllers Market |

| Accounted market size in 2023 | US$ 170 million |

| Forecasted market size in 2030 | US$ 226 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mitsubishi Electric, ABB, EIKO SOKKI, Erhardt+Leimer, OGURA CLUTCH, Nireco, Maxcess, SINFONIA TECHNOLOGY, FMS Technology, Montalvo, Double E Company, Re Spa, Cleveland Motion Controls, Dover Flexo Electronics, REDEX, Nexen Group, Wuhan True Engin Technology, BOSENSE CORPORATION, ZXTEC, Dongye Electromechanical Co.,Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |