What is Global Automotive Front Subframe Market?

The Global Automotive Front Subframe Market is a crucial segment within the automotive industry, focusing on the production and distribution of subframes that are integral components of vehicle chassis. A subframe is essentially a structural component of a vehicle, providing a mounting space for the engine, transmission, and suspension system, thereby contributing significantly to the vehicle's overall strength and stability. This market's significance stems from its direct impact on vehicle performance, safety, and durability. As automotive manufacturers continually strive for innovation in vehicle design and performance, the demand for high-quality, durable subframes has surged. The market caters to a wide range of vehicles, including passenger cars and commercial vehicles, and encompasses various materials such as steel and aluminum alloys, each offering distinct advantages in terms of strength, weight, and corrosion resistance. The evolution of this market is closely tied to advancements in automotive technology and the shifting preferences of consumers towards more efficient, safer, and environmentally friendly vehicles. As of 2023, the market's expansion reflects the automotive industry's broader trends towards electrification, lightweight materials, and enhanced safety features, positioning the Global Automotive Front Subframe Market as a key area of focus for manufacturers and investors alike.

Steel Subframe, Aluminum Alloy Subframe in the Global Automotive Front Subframe Market:

Diving into the specifics of the Global Automotive Front Subframe Market, we find two primary materials dominating the scene: Steel Subframes and Aluminum Alloy Subframes. Steel subframes have been the backbone of vehicle construction for decades, prized for their robustness, durability, and cost-effectiveness. Steel's inherent strength allows for the design of subframes that can withstand significant stress and impact, making them a go-to choice for a wide range of vehicles, especially in segments where cost considerations outweigh the benefits of weight reduction. On the other hand, Aluminum Alloy Subframes represent the industry's shift towards lightweighting strategies. Aluminum, being significantly lighter than steel, offers the advantage of reducing the overall vehicle weight, which in turn enhances fuel efficiency and reduces emissions – a critical consideration in today's environmentally conscious market. However, this comes at a higher material and manufacturing cost, given aluminum's challenges in terms of formability and the need for specialized welding techniques. The choice between steel and aluminum alloy subframes is influenced by various factors, including vehicle type, performance requirements, and cost constraints. Manufacturers weigh these considerations carefully, often opting for a mixed-material strategy to balance performance, cost, and environmental impact. As the automotive industry continues to evolve, driven by advancements in material science and manufacturing technologies, the Global Automotive Front Subframe Market is expected to see further innovations, with composite materials and new alloys potentially entering the fray, offering even greater opportunities for weight reduction and performance enhancement.

Passenger Cars, Commercial Vehicles in the Global Automotive Front Subframe Market:

The usage of the Global Automotive Front Subframe Market spans across two major vehicle categories: Passenger Cars and Commercial Vehicles. In the realm of Passenger Cars, subframes play a pivotal role in enhancing vehicle safety, driving comfort, and performance. Given the diverse range of passenger vehicles, from compact cars to luxury SUVs, the demand for subframes varies significantly, with manufacturers opting for materials and designs that align with the specific performance and cost objectives of each vehicle segment. For instance, luxury and performance-oriented models are more likely to incorporate aluminum alloy subframes to reduce weight and improve handling, while more budget-friendly models might stick with steel subframes for their cost-effectiveness and durability. On the commercial vehicle front, the emphasis is on robustness, longevity, and load-bearing capacity. Commercial vehicles, including trucks and buses, require subframes that can withstand heavy loads, harsh operating conditions, and extended use cycles. Here, steel subframes are predominantly used, given their superior strength and resistance to wear and tear. However, with increasing regulatory pressure to reduce emissions and improve fuel efficiency, even the commercial vehicle segment is witnessing a gradual shift towards lighter materials, including aluminum alloys, for certain applications where weight reduction can be achieved without compromising on strength and durability. This nuanced approach to subframe material selection underscores the market's complexity and the critical role of subframes in meeting the diverse needs of the automotive sector.

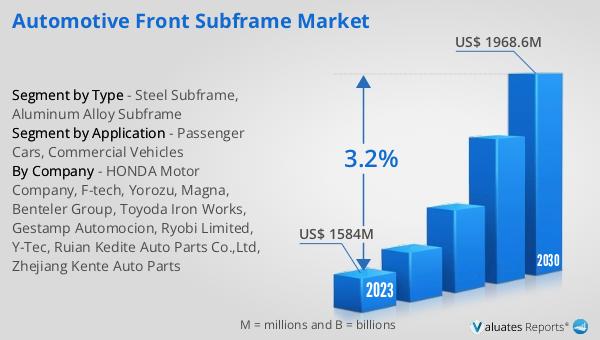

Global Automotive Front Subframe Market Outlook:

Regarding the market outlook for the Global Automotive Front Subframe Market, it's noteworthy that the sector has been valued at US$ 1584 million as of 2023. Looking ahead, projections suggest a promising growth trajectory, with the market expected to ascend to US$ 1968.6 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 3.2% throughout the forecast period spanning from 2024 to 2030. Such an optimistic forecast underscores the market's resilience and its capacity to adapt to the evolving demands of the automotive industry. Factors contributing to this positive outlook include technological advancements in vehicle design and manufacturing, a heightened focus on vehicle safety and performance, and the ongoing shift towards more fuel-efficient, environmentally friendly vehicles. As manufacturers continue to innovate and invest in research and development, the Global Automotive Front Subframe Market is poised to play a pivotal role in shaping the future of automotive design and construction, reflecting broader trends towards sustainability and efficiency in the automotive sector.

| Report Metric | Details |

| Report Name | Automotive Front Subframe Market |

| Accounted market size in 2023 | US$ 1584 million |

| Forecasted market size in 2030 | US$ 1968.6 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HONDA Motor Company, F-tech, Yorozu, Magna, Benteler Group, Toyoda Iron Works, Gestamp Automocion, Ryobi Limited, Y-Tec, Ruian Kedite Auto Parts Co.,Ltd, Zhejiang Kente Auto Parts |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |