What is Global Automatic Brick Making Machine Market?

The Global Automatic Brick Making Machine Market refers to the worldwide industry focused on the production and sale of machines that automate the brick-making process. These machines are designed to produce bricks efficiently and consistently, reducing the need for manual labor and increasing production speed. The market encompasses various types of machines, including fully automatic and semi-automatic models, which cater to different production needs and scales. The demand for these machines is driven by the growing construction industry, urbanization, and the need for sustainable building materials. As countries continue to develop and infrastructure projects expand, the market for automatic brick-making machines is expected to grow, offering numerous opportunities for manufacturers and suppliers.

Fully Automatic Brick Making Machine, Semi-automatic Brick Making Machine in the Global Automatic Brick Making Machine Market:

Fully Automatic Brick Making Machines are advanced systems designed to produce bricks with minimal human intervention. These machines are equipped with sophisticated technology that allows for the complete automation of the brick-making process, from raw material feeding to brick molding, curing, and stacking. The primary advantage of fully automatic machines is their high production capacity and efficiency. They can produce a large number of bricks in a short period, making them ideal for large-scale construction projects and industrial applications. Additionally, these machines ensure consistent quality and uniformity in the bricks produced, which is crucial for maintaining structural integrity in construction. On the other hand, Semi-automatic Brick Making Machines require some level of human intervention during the production process. While they automate certain steps, such as brick molding and curing, other tasks like raw material feeding and brick stacking may still need manual input. These machines are typically more affordable than fully automatic models and are suitable for small to medium-sized production facilities. They offer a balance between automation and cost, making them an attractive option for businesses that do not require the high output of fully automatic machines but still want to improve efficiency and reduce labor costs. In the Global Automatic Brick Making Machine Market, both fully automatic and semi-automatic machines play significant roles. Fully automatic machines are often preferred in regions with high labor costs and large-scale construction activities, such as urban areas and industrial zones. Their ability to produce high-quality bricks quickly and consistently makes them a valuable asset for large construction companies and infrastructure projects. Moreover, the advanced technology used in these machines often includes features like remote monitoring and control, which further enhances their efficiency and ease of use. Semi-automatic machines, however, find their niche in areas where labor is more affordable, and the scale of production is smaller. These machines are commonly used in rural areas and small to medium-sized enterprises that cater to local construction needs. They provide a cost-effective solution for brick production, allowing businesses to increase their output without the significant investment required for fully automatic machines. Additionally, semi-automatic machines are often easier to maintain and repair, which can be a crucial factor for businesses operating in regions with limited access to technical support. Both types of machines contribute to the overall growth of the Global Automatic Brick Making Machine Market by catering to different segments of the construction industry. The choice between fully automatic and semi-automatic machines depends on various factors, including production requirements, budget, and the availability of skilled labor. As the construction industry continues to evolve, the demand for both types of machines is expected to remain strong, driven by the need for efficient, cost-effective, and sustainable brick production solutions.

Building Construction, Industrial, Others in the Global Automatic Brick Making Machine Market:

The usage of Global Automatic Brick Making Machines spans various sectors, including Building Construction, Industrial, and Others. In the Building Construction sector, these machines are indispensable for producing the bricks needed for residential, commercial, and infrastructure projects. The ability to produce high-quality bricks quickly and consistently ensures that construction projects can proceed without delays, maintaining timelines and budgets. Fully automatic machines, in particular, are favored in large-scale construction projects where the demand for bricks is high, and the quality of materials is paramount. These machines help in reducing labor costs and increasing productivity, making them a valuable asset for construction companies. In the Industrial sector, automatic brick-making machines are used to produce specialized bricks for various industrial applications. These may include refractory bricks for high-temperature environments, acid-resistant bricks for chemical plants, and other customized bricks designed to meet specific industrial requirements. The precision and consistency offered by fully automatic machines ensure that these specialized bricks meet the stringent quality standards required in industrial applications. Semi-automatic machines also play a role in this sector, particularly in smaller industrial facilities where the production scale does not justify the investment in fully automatic systems. Beyond Building Construction and Industrial sectors, automatic brick-making machines are also used in other areas such as landscaping, road construction, and public works. In landscaping, bricks produced by these machines are used for creating pathways, garden walls, and other decorative elements. The ability to produce bricks in various shapes, sizes, and colors allows for creative and customized landscaping solutions. In road construction, bricks are used for paving and creating durable road surfaces. The consistent quality and strength of bricks produced by automatic machines ensure that the roads are long-lasting and require minimal maintenance. Public works projects, such as the construction of schools, hospitals, and community centers, also benefit from the use of automatic brick-making machines. These projects often require large quantities of bricks within tight timelines, making fully automatic machines an ideal choice. The efficiency and speed of these machines help in meeting project deadlines and ensuring that public infrastructure is built to high standards. Semi-automatic machines are also used in smaller public works projects, providing a cost-effective solution for producing the necessary bricks. Overall, the usage of Global Automatic Brick Making Machines in various sectors highlights their versatility and importance in modern construction and industrial applications. Whether it is for building homes, factories, roads, or public facilities, these machines provide a reliable and efficient solution for producing high-quality bricks. The choice between fully automatic and semi-automatic machines depends on the specific needs of each sector, with both types offering unique advantages. As the demand for sustainable and efficient construction solutions continues to grow, the role of automatic brick-making machines in these sectors is expected to become even more significant.

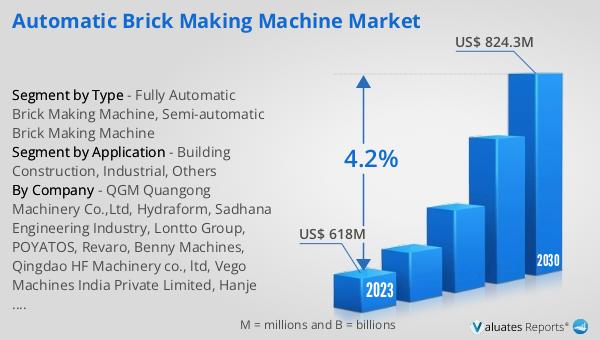

Global Automatic Brick Making Machine Market Outlook:

The global Automatic Brick Making Machine market was valued at US$ 618 million in 2023 and is anticipated to reach US$ 824.3 million by 2030, witnessing a CAGR of 4.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for efficient and automated brick production solutions. The rise in construction activities, urbanization, and the need for sustainable building materials are key factors contributing to this growth. As more countries invest in infrastructure development and modernize their construction practices, the adoption of automatic brick-making machines is expected to rise. The market's growth is also supported by technological advancements in machine design and functionality, which enhance production efficiency and brick quality. Overall, the global Automatic Brick Making Machine market is poised for significant expansion, offering numerous opportunities for manufacturers and suppliers to capitalize on the growing demand for automated brick production solutions.

| Report Metric | Details |

| Report Name | Automatic Brick Making Machine Market |

| Accounted market size in 2023 | US$ 618 million |

| Forecasted market size in 2030 | US$ 824.3 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | QGM Quangong Machinery Co.,Ltd, Hydraform, Sadhana Engineering Industry, Lontto Group, POYATOS, Revaro, Benny Machines, Qingdao HF Machinery co., ltd, Vego Machines India Private Limited, Hanje Hydrotech, Vishwakarma Creative Engineering Pvt. Ltd, Aimix Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |