What is Global Industrial Metrology Equipment Market?

The Global Industrial Metrology Equipment Market encompasses a wide range of devices and systems used for measurement, quality control, and inspection in various industrial sectors. This market is crucial for ensuring the precision and efficiency of manufacturing processes, contributing significantly to the advancement of technology and production standards. Industrial metrology equipment plays a pivotal role in enhancing product quality, optimizing manufacturing processes, and ensuring compliance with international standards. The equipment includes devices for measuring dimensions, temperature, pressure, and other physical quantities with high accuracy. These tools are indispensable in industries where precision is paramount, such as aerospace, automotive, electronics, and healthcare. The demand for industrial metrology equipment is driven by the growing emphasis on quality and reliability in manufacturing, the increasing complexity of industrial products, and the rapid advancement of manufacturing technologies. As industries continue to evolve and adopt more sophisticated manufacturing techniques, the importance of industrial metrology equipment in maintaining high standards of precision and efficiency is expected to grow, making it a key component of modern industrial operations.

Coordinate Measuring Machine, Optical Digitizer and Scanner, Measuring Instrument, X-Ray and Computed Tomography, Automated Optical Inspection, 2D Equipment in the Global Industrial Metrology Equipment Market:

Coordinate Measuring Machines (CMMs), Optical Digitizers and Scanners (ODS), Measuring Instruments, X-Ray and Computed Tomography (CT) systems, Automated Optical Inspection (AOI) devices, and 2D Equipment are integral components of the Global Industrial Metrology Equipment Market, each serving unique functions in precision measurement and quality control across various industries. CMMs offer precise measurements of an object's geometry using a probing system, making them essential for ensuring the accuracy of manufactured parts. ODS technologies, including laser scanners, provide non-contact measurement solutions, capturing detailed surface data for complex shapes and forms, which is crucial in design and manufacturing processes. Measuring Instruments encompass a broad category of tools, including calipers, micrometers, and gauges, used for assessing dimensions, angles, and other physical properties of objects with high precision. X-Ray and CT systems offer non-destructive testing methods, allowing for the internal examination of components without altering their state, which is vital in detecting defects and ensuring internal quality. AOI systems are employed in electronics manufacturing to inspect circuit boards and detect defects, ensuring the functionality and reliability of electronic devices. Lastly, 2D Equipment, such as profile projectors and digital microscopes, provides detailed inspections of object surfaces, supporting quality control in manufacturing. Together, these technologies form the backbone of the Global Industrial Metrology Equipment Market, facilitating advancements in manufacturing accuracy, product quality, and process efficiency.

Aerospace and Defense, Automotive, Manufacturing, Semiconductor, Others in the Global Industrial Metrology Equipment Market:

In the realms of Aerospace and Defense, Automotive, Manufacturing, Semiconductor, and other sectors, the Global Industrial Metrology Equipment Market finds extensive applications, each industry benefiting uniquely from its capabilities. In Aerospace and Defense, precision is paramount; metrology equipment ensures the reliability and safety of components subjected to extreme conditions. This sector relies heavily on CMMs, X-Ray, and CT systems for the meticulous inspection of parts, where even minor discrepancies can have significant consequences. The Automotive industry, with its emphasis on safety, efficiency, and reliability, utilizes metrology equipment for quality control of complex parts and assemblies, ensuring vehicles meet stringent performance standards. Manufacturing, encompassing a wide range of products, from consumer goods to industrial machinery, employs metrology equipment to maintain high-quality standards, reduce waste, and increase productivity. The Semiconductor industry, where the scale of operations is microscopic, and the margin for error is virtually nil, depends on metrology equipment like AOI systems and high-resolution imaging technologies to inspect wafers and chips, ensuring the functionality of electronic devices. Other sectors, including energy, healthcare, and construction, also benefit from the precision and efficiency offered by metrology equipment, highlighting its versatility and critical role in modern industrial operations.

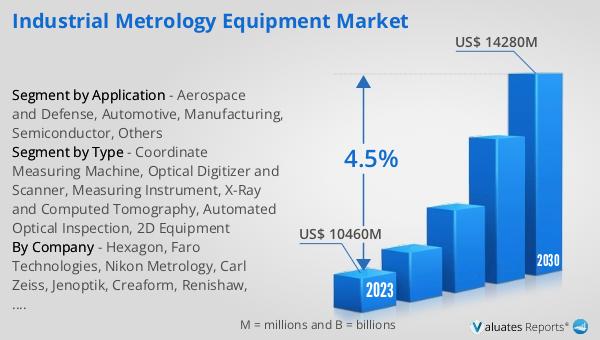

Global Industrial Metrology Equipment Market Outlook:

The market outlook for Global Industrial Metrology Equipment presents a promising future, with the market's value estimated at US$ 10,460 million in 2023, and projections suggesting it will ascend to US$ 14,280 million by 2030. This growth trajectory, marked by a Compound Annual Growth Rate (CAGR) of 4.5% during the forecast period from 2024 to 2030, underscores the increasing reliance on and demand for industrial metrology equipment across various sectors. This anticipated expansion reflects the evolving needs of industries for higher precision, efficiency, and quality control in manufacturing processes. As technological advancements continue to drive the development of more sophisticated and accurate metrology equipment, the market is expected to witness sustained growth. This growth is not just a testament to the technological advancements in metrology equipment but also to the growing recognition of the critical role that precision measurement plays in enhancing product quality, reducing waste, and improving overall manufacturing efficiency. The Global Industrial Metrology Equipment Market's outlook is thus characterized by robust growth prospects, driven by the continuous need for innovation and precision in industrial operations.

| Report Metric | Details |

| Report Name | Industrial Metrology Equipment Market |

| Accounted market size in 2023 | US$ 10460 million |

| Forecasted market size in 2030 | US$ 14280 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hexagon, Faro Technologies, Nikon Metrology, Carl Zeiss, Jenoptik, Creaform, Renishaw, KLA-Tencor, Applied Materials, Perceptron, GOM, Automated Precision, JLM Advanced Technical Services, Precision Products, Carmar Accuracy, Pollen Metrology, Cairnhill Metrology, Att Metrology Services, Trimet Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |