What is Global Cut-to-length Line System Market?

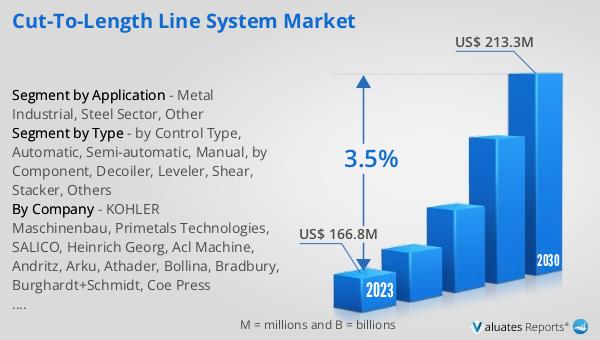

The Global Cut-to-length Line System Market is an intricate network that spans across various industries, offering a tailored approach to handling sheet metal. This system is designed to uncoil, straighten, measure, and then cut the metal into precise lengths, catering to the specific needs of different sectors. At its core, the market is driven by the demand for efficiency and precision in metal fabrication. As industries strive for optimization, the cut-to-length line system stands out as a pivotal solution, ensuring materials are processed quickly, accurately, and with minimal waste. This market's significance is underscored by its valuation at US$ 166.8 million in 2023, with projections suggesting a growth to US$ 213.3 million by 2030. This growth trajectory, marked by a compound annual growth rate (CAGR) of 3.5%, reflects the increasing reliance on these systems across the globe. Key players like ANDRITZ Group and Heinrich Georg GmbH have established a strong foothold, collectively holding over 20% of the market share. Geographically, Asia-Pacific leads the charge, accounting for over 40% of the market, followed by North America and Europe. This distribution highlights the global demand for cut-to-length line systems, underscoring their critical role in modern manufacturing and construction processes.

Automatic Cut-to-length Line System, Semi-automatic Cut-to-length Line System in the Global Cut-to-length Line System Market:

Diving deeper into the Global Cut-to-length Line System Market, we find two primary categories: Automatic and Semi-automatic systems. Automatic Cut-to-length Line Systems represent the pinnacle of efficiency and precision. These systems are fully automated, requiring minimal human intervention, which significantly reduces the likelihood of errors and increases production speed. They are equipped with advanced features like computer-controlled measuring, cutting, and stacking, making them ideal for high-volume production environments where time and accuracy are of the essence. On the other hand, Semi-automatic Cut-to-length Line Systems strike a balance between automation and manual control. These systems still automate the core processes of uncoiling, straightening, and cutting but may require manual setup or oversight for certain operations. This blend allows for flexibility in production and can be particularly beneficial in settings where production volumes are lower or where material variability requires a more hands-on approach. Both systems play vital roles within the Global Cut-to-length Line System Market, catering to a wide range of industrial needs. From construction and automotive to aerospace and beyond, these systems provide the backbone for precise material processing, ensuring that industries can meet their exacting standards and production goals.

Construction, Aerospace, Automotive, Others in the Global Cut-to-length Line System Market:

The usage of the Global Cut-to-length Line System Market spans several key industries, each with its unique demands and applications. In construction, these systems are indispensable for preparing metal sheets and panels used in building structures, roofing, and cladding. The precision and efficiency of cut-to-length lines ensure that materials are optimized for strength and durability, contributing to safer and more reliable construction projects. Aerospace applications demand the utmost in precision and quality, as even minor discrepancies can have significant implications. Cut-to-length line systems in this sector are used to process materials for aircraft components, ensuring that each piece meets the rigorous standards of the industry. The automotive industry benefits from these systems in manufacturing parts and components for vehicles. From body panels to structural elements, the ability to cut materials accurately and efficiently is crucial for maintaining production timelines and quality standards. Other sectors, including electronics, manufacturing, and energy, also rely on cut-to-length line systems for their material processing needs. The versatility and adaptability of these systems make them a cornerstone in modern industrial operations, driving efficiency and innovation across a broad spectrum of applications.

Global Cut-to-length Line System Market Outlook:

The market outlook for the Global Cut-to-length Line System Market presents a promising future, with its value projected to increase from US$ 166.8 million in 2023 to US$ 213.3 million by 2030. This growth, characterized by a steady CAGR of 3.5% during the forecast period from 2024 to 2030, signifies the expanding reliance on these systems across various industries. The market is not only growing in terms of value but also in its geographical reach and application diversity. With Asia-Pacific leading the market share, followed closely by North America and Europe, it's evident that the demand for cut-to-length line systems transcends regional boundaries, reflecting a global need for efficient and precise material processing solutions. Companies like ANDRITZ Group and Heinrich Georg GmbH are at the forefront, driving innovation and setting standards for quality and reliability. This outlook underscores the critical role of cut-to-length line systems in modern manufacturing and construction, highlighting their contribution to the global economy and the advancement of technology in material processing.

| Report Metric | Details |

| Report Name | Cut-to-length Line System Market |

| Accounted market size in 2023 | US$ 166.8 million |

| Forecasted market size in 2030 | US$ 213.3 million |

| CAGR | 3.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heinrich Georg, ARKU, Kohler Maschinenbau, FIMI Fabbrica Impianti Macchine Industriali, Dimeco, GSW Schwabe, Athader, Sacform, ACL Machine, Bollina, Bradbury Group, Burghardt+Schmidt, Delta Steel Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |