What is Aluminum Alloy Automotive Die Castings - Global Market?

The Aluminum Alloy Automotive Die Castings - Global Market encompasses a specialized sector within the automotive industry, focusing on the production and use of aluminum alloy components through die casting methods. This market is significant due to the automotive industry's shift towards lightweight materials to enhance fuel efficiency and reduce emissions. Aluminum alloys, known for their strength, lightweight, and corrosion resistance, are increasingly preferred for automotive parts. The global market for these components is driven by the demand for more fuel-efficient vehicles and the automotive industry's growth, especially in emerging economies. As vehicles evolve with more complex and lightweight designs, the role of aluminum alloy die castings becomes increasingly critical. This market's dynamics are influenced by technological advancements in die casting processes, the availability of aluminum alloys, and the automotive industry's regulatory landscape aiming for lower emissions and higher efficiency. The market's expansion is also propelled by the growing electric vehicle sector, which relies heavily on lightweight materials like aluminum to improve battery range and overall efficiency.

Pressure Die Casting, Vacuum Die Casting, Others in the Aluminum Alloy Automotive Die Castings - Global Market:

Delving into the specifics of the Aluminum Alloy Automotive Die Castings - Global Market, it's essential to understand the different processes involved, namely Pressure Die Casting, Vacuum Die Casting, among others. Pressure Die Casting is a prevalent method due to its ability to produce large volumes of parts with excellent dimensional accuracy and smooth surfaces, which is crucial for automotive components. This process involves injecting molten aluminum alloy under high pressure into a steel mold, making it suitable for creating complex shapes that require minimal machining. On the other hand, Vacuum Die Casting, another pivotal technique, enhances the quality of the castings by removing air from the mold cavity before and during the injection of the molten metal. This process reduces porosity, improving the mechanical properties and surface finish of the parts, which is particularly beneficial for critical automotive applications. Other methods in the market include squeeze casting and semi-solid metal casting, each offering unique advantages in terms of part quality and production efficiency. These processes cater to the automotive industry's need for durable, lightweight, and high-quality aluminum alloy components, driving the global market's growth by meeting the stringent requirements of automotive manufacturers for performance, safety, and environmental compliance.

Body Parts, Engine Parts, Gearbox Parts, Others in the Aluminum Alloy Automotive Die Castings - Global Market:

In the realm of the Aluminum Alloy Automotive Die Castings - Global Market, the usage of these components spans various critical areas, including Body Parts, Engine Parts, Gearbox Parts, among others. Body parts made from aluminum alloy die castings, such as door frames, hoods, and chassis components, contribute significantly to vehicle lightweighting, a crucial factor in enhancing fuel efficiency and reducing emissions. Engine parts, including engine blocks and cylinder heads made through die casting, benefit from aluminum's excellent thermal properties, contributing to better heat dissipation and overall engine performance. Gearbox parts, another critical application, utilize aluminum alloys for their strength-to-weight ratio, improving vehicle dynamics and power transmission efficiency. The "Others" category encompasses a wide range of automotive components, including suspension systems and various interior and exterior trim parts, all benefiting from the advantages of aluminum alloy die castings. This widespread use across different vehicle areas underscores the material's versatility and the die casting process's capability to meet the automotive industry's stringent requirements for durability, performance, and aesthetics. The global market's growth is thus propelled by the expanding application scope of aluminum alloy die castings in the automotive sector, reflecting the industry's ongoing pursuit of innovation and sustainability.

Aluminum Alloy Automotive Die Castings - Global Market Outlook:

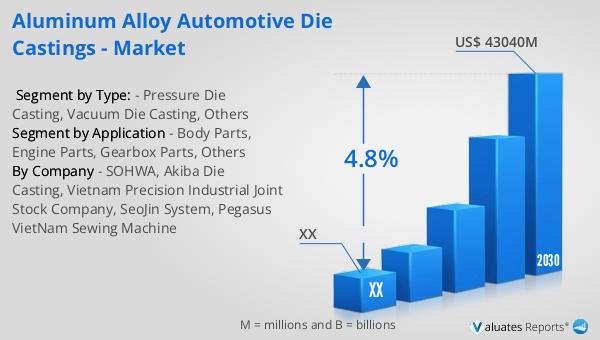

The market outlook for Aluminum Alloy Automotive Die Castings reveals a promising trajectory, with the industry's value estimated at US$ 32,030 million in 2023, projected to reach US$ 43,040 million by 2030, growing at a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. This growth is reflective of the automotive industry's concentrated efforts in the three major continents of Asia, Europe, and North America, which collectively harbor over 90% of the world's automobile production. Specifically, Asia leads with a 56% share in global automobile production, followed by Europe at 20%, and North America at 16%. These figures underscore the significant role these regions play in the automotive sector, driving the demand for aluminum alloy automotive die castings. The market's expansion is fueled by the automotive industry's continuous push towards lightweight materials to achieve better fuel efficiency and lower emissions, alongside the burgeoning electric vehicle market that heavily relies on lightweight components for improved performance. The global market's growth trajectory is thus anchored in the automotive industry's evolving needs and the strategic importance of aluminum alloy die castings in meeting these demands.

| Report Metric | Details |

| Report Name | Aluminum Alloy Automotive Die Castings - Market |

| Forecasted market size in 2030 | US$ 43040 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SOHWA, Akiba Die Casting, Vietnam Precision Industrial Joint Stock Company, SeoJin System, Pegasus VietNam Sewing Machine |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |