What is Global Glass Fiber in Automotive Composites Market?

The Global Glass Fiber in Automotive Composites Market is a dynamic sector that plays a pivotal role in the automotive industry, focusing on the use of glass fiber materials to enhance vehicle performance, safety, and efficiency. Glass fiber, known for its strength, durability, and lightweight properties, is increasingly being incorporated into automotive components to reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. This market encompasses a wide range of applications, from structural parts to exterior and interior components, leveraging the material's versatility to meet stringent automotive standards. As the automotive industry continues to evolve with a growing emphasis on sustainability and innovation, the demand for glass fiber composites is expected to rise. This trend is driven by the need for vehicles that are not only environmentally friendly but also offer superior performance and safety features. The Global Glass Fiber in Automotive Composites Market is thus at the forefront of transforming the automotive landscape, offering solutions that meet the dual demands of eco-friendliness and advanced functionality.

SheetMoldingCompound(SMC), BulkMoldingCompound(BMC), GlassMatThermoplastic(GMT), ShortFiberThermoplastic(SFT), LongFiberThermoplastic(LFT), ContinuousFiberThermoplastic(CFT), PhenolicMoldingCompound(PMC), Others in the Global Glass Fiber in Automotive Composites Market:

The Global Glass Fiber in Automotive Composites Market is segmented into various types, including Sheet Molding Compound (SMC), Bulk Molding Compound (BMC), Glass Mat Thermoplastic (GMT), Short Fiber Thermoplastic (SFT), Long Fiber Thermoplastic (LFT), Continuous Fiber Thermoplastic (CFT), Phenolic Molding Compound (PMC), among others, each serving distinct purposes in automotive manufacturing. SMC and BMC are widely used for their strength and ability to mold into complex shapes, making them ideal for body panels and structural components. GMT, on the other hand, is favored for its lightweight and impact resistance, often used in underbody systems and front-end modules. SFT and LFT are notable for their excellent mechanical properties and are typically employed in interior, under-the-hood, and structural applications due to their ability to enhance strength and reduce weight. CFT stands out for its superior strength and stiffness, making it suitable for critical structural components. PMC is utilized for its fire resistance and thermal insulation, often found in engine compartments and electrical applications. Each of these materials plays a crucial role in the automotive industry's shift towards lighter, more efficient, and safer vehicles, highlighting the diverse applications and benefits of glass fiber composites in modern automotive design and manufacturing.

Passenger Car, Commercial Vehicle in the Global Glass Fiber in Automotive Composites Market:

In the realm of the Global Glass Fiber in Automotive Composites Market, the usage spans across Passenger Cars and Commercial Vehicles, each benefiting uniquely from the incorporation of glass fiber composites. In Passenger Cars, these materials contribute significantly to enhancing safety, fuel efficiency, and performance by reducing the vehicle's overall weight while maintaining structural integrity. Components such as door modules, front-end modules, bumpers, and underbody shields are commonly made from glass fiber composites, offering improved durability and resistance to impacts. For Commercial Vehicles, the emphasis on durability, longevity, and payload capacity sees glass fiber composites being used in body panels, frames, and interior components. The lightweight nature of these materials helps in increasing fuel efficiency and reducing emissions, a critical factor for fleet operators mindful of operational costs and environmental regulations. Furthermore, the versatility of glass fiber composites allows for design flexibility, enabling the creation of vehicles that meet the specific demands of commercial use while adhering to safety and performance standards. The application of glass fiber in automotive composites thus spans a broad spectrum, underlining its importance in driving advancements in both passenger and commercial vehicle sectors.

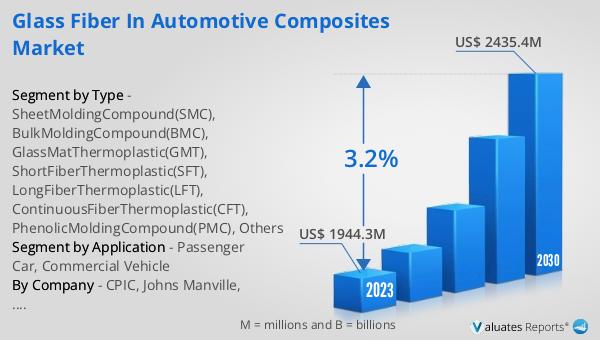

Global Glass Fiber in Automotive Composites Market Outlook:

The market outlook for the Global Glass Fiber in Automotive Composites Market presents a promising future, with its valuation at US$ 1944.3 million in 2023, expected to ascend to US$ 2435.4 million by 2030, marking a Compound Annual Growth Rate (CAGR) of 3.2% during the forecast period of 2024 to 2030. Currently, the automotive industry's geographical concentration highlights more than 90% of the world's vehicles being produced across Asia, Europe, and North America. Specifically, Asia leads the production with a 56% share, followed by Europe at 20%, and North America at 16%. This distribution underscores the significant role these regions play in the automotive sector, driving the demand for glass fiber composites. The material's attributes, such as lightweight, strength, and flexibility, align with the industry's evolving needs for fuel efficiency, emission reduction, and enhanced performance. As these regions continue to dominate automobile production, the demand for glass fiber in automotive composites is anticipated to grow, reflecting the industry's shift towards more sustainable and efficient manufacturing practices.

| Report Metric | Details |

| Report Name | Glass Fiber in Automotive Composites Market |

| Accounted market size in 2023 | US$ 1944.3 million |

| Forecasted market size in 2030 | US$ 2435.4 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | CPIC, Johns Manville, Jushi Group, Lanxess, Owens Corning |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |