What is Global 300 mm Wafer Electrostatic Chucks (ESC) Market?

The Global 300 mm Wafer Electrostatic Chucks (ESC) Market is a specialized segment within the semiconductor equipment industry, focusing on the technology used to hold and release wafers during the fabrication process. Electrostatic chucks play a crucial role in the manufacturing of semiconductor devices, utilizing electrical charges to secure wafers during the etching, deposition, and inspection stages of production. The 300 mm wafer size has become a standard in the industry due to its efficiency and higher throughput capabilities compared to its predecessors. This market's significance lies in its contribution to the advancement of semiconductor technology, enabling the production of more powerful and compact electronic devices. As the demand for sophisticated electronics continues to rise, the need for efficient and reliable electrostatic chucks also grows, driving the market forward. The Global 300 mm Wafer Electrostatic Chucks (ESC) Market encompasses a range of products, technologies, and services, catering to the needs of semiconductor manufacturers worldwide.

Coulomb Type Electrostatic Chuck, Johnsen-Rahbek (JR) Type Electrostatic Chuck in the Global 300 mm Wafer Electrostatic Chucks (ESC) Market:

Diving into the specifics, the Global 300 mm Wafer Electrostatic Chucks (ESC) Market features two primary types of chucks: Coulomb Type and Johnsen-Rahbek (JR) Type. The Coulomb Type Electrostatic Chuck operates on the principle of electrostatic force generated by the direct application of voltage, which attracts the wafer to the chuck surface. This type is known for its simplicity and effectiveness in holding the wafer securely, making it suitable for various applications within semiconductor manufacturing. On the other hand, the Johnsen-Rahbek (JR) Type Electrostatic Chuck utilizes not only electrostatic forces but also relies on a real area of contact and high surface energy to enhance the holding force. This method results in a stronger bond between the wafer and the chuck, providing better thermal conductivity, which is crucial for processes that require precise temperature control. Both types of electrostatic chucks are integral to the Global 300 mm Wafer Electrostatic Chucks (ESC) Market, each serving distinct purposes based on their unique properties and advantages. Manufacturers and engineers select the type of chuck based on specific requirements of the semiconductor fabrication process, including the nature of the materials involved, the desired precision, and the thermal management needs. The ongoing development and refinement of these technologies reflect the market's commitment to supporting the semiconductor industry's evolving demands, ensuring that electronic devices continue to advance in performance and functionality.

Fab, Semiconductor Equipment Factory in the Global 300 mm Wafer Electrostatic Chucks (ESC) Market:

In the realm of semiconductor manufacturing, the Global 300 mm Wafer Electrostatic Chucks (ESC) Market finds its application primarily in two critical areas: Fab and Semiconductor Equipment Factories. In the fabrication plants, or Fabs, electrostatic chucks are indispensable for the precise handling of wafers through various stages of the semiconductor production process. These chucks ensure that wafers are securely held in place during high-precision operations such as lithography, etching, and deposition, minimizing the risk of contamination or damage. The ability to maintain wafer stability at elevated temperatures and under vacuum conditions is particularly valued in these settings. Meanwhile, in Semiconductor Equipment Factories, where the machinery used in Fabs is designed and assembled, electrostatic chucks are crucial for testing and calibrating equipment under conditions that mimic actual production environments. This ensures that the equipment delivers optimal performance and reliability when deployed in semiconductor manufacturing facilities. The use of electrostatic chucks in these areas underscores their importance not only in the direct fabrication of semiconductor devices but also in the broader ecosystem that supports the semiconductor industry. By enabling precise control and handling of wafers, electrostatic chucks contribute significantly to the advancement of semiconductor technology, facilitating the production of increasingly sophisticated and miniaturized electronic components.

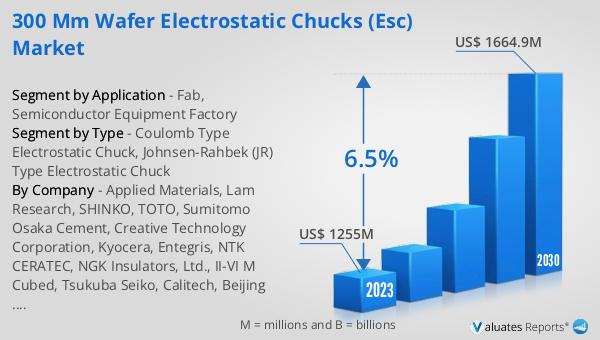

Global 300 mm Wafer Electrostatic Chucks (ESC) Market Outlook:

Regarding the market outlook for the Global 300 mm Wafer Electrostatic Chucks (ESC) Market, it was reported to have a valuation of US$ 1255 million in the year 2023. The market is projected to experience growth, reaching an estimated value of US$ 1664.9 million by the year 2030. This growth trajectory represents a Compound Annual Growth Rate (CAGR) of 6.5% over the forecast period spanning from 2024 to 2030. Within this competitive landscape, Applied Materials emerged as a leading player, capturing a substantial 43.84% share of the market revenue. Following closely, Lam Research secured a 31.58% share, demonstrating its significant presence in the market. Additionally, SHINKO made its mark by holding a 10.21% share of the market revenue. These figures highlight the dynamic nature of the Global 300 mm Wafer Electrostatic Chucks (ESC) Market, showcasing the competitive edge and innovation-driven approach of the leading companies. Their contributions are pivotal in driving the market forward, reflecting the ongoing demand for advanced semiconductor manufacturing solutions and the critical role of electrostatic chucks in meeting this demand.

| Report Metric | Details |

| Report Name | 300 mm Wafer Electrostatic Chucks (ESC) Market |

| Accounted market size in 2023 | US$ 1255 million |

| Forecasted market size in 2030 | US$ 1664.9 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Applied Materials, Lam Research, SHINKO, TOTO, Sumitomo Osaka Cement, Creative Technology Corporation, Kyocera, Entegris, NTK CERATEC, NGK Insulators, Ltd., II-VI M Cubed, Tsukuba Seiko, Calitech, Beijing U-PRECISION TECH CO., LTD. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |