What is Global Rotation Torque Sensors Market?

The Global Rotation Torque Sensors Market is a specialized segment within the broader sensor industry, focusing on devices that measure the torque or rotational force applied to an object. These sensors are crucial in various applications, providing precise measurements that help in monitoring and controlling mechanical systems. Torque sensors are used in industries such as automotive, aerospace, marine, and industrial machinery, where they play a vital role in ensuring the efficiency and safety of operations. The market for these sensors is driven by the increasing demand for automation and the need for accurate torque measurement in complex machinery. As industries continue to evolve and adopt more advanced technologies, the demand for reliable and high-performance torque sensors is expected to grow. These sensors not only enhance the performance of machines but also contribute to energy efficiency and cost savings by preventing mechanical failures and optimizing maintenance schedules. The Global Rotation Torque Sensors Market is characterized by continuous innovation, with manufacturers focusing on developing sensors that offer higher accuracy, durability, and ease of integration into existing systems. As a result, this market is poised for significant growth, driven by technological advancements and the expanding scope of applications across various sectors.

Dynamic Type, Static Type in the Global Rotation Torque Sensors Market:

In the Global Rotation Torque Sensors Market, two primary types of sensors are prevalent: Dynamic Type and Static Type. Dynamic torque sensors are designed to measure torque in rotating systems, making them ideal for applications where the torque varies over time. These sensors are commonly used in automotive and aerospace industries, where they help in monitoring the performance of engines and other rotating components. Dynamic torque sensors are known for their ability to provide real-time data, which is crucial for applications that require continuous monitoring and control. They are typically installed in systems where the torque is not constant, and the sensor needs to capture the variations accurately. On the other hand, Static Type torque sensors are used in applications where the torque is constant or changes very slowly. These sensors are often employed in industrial machinery and other applications where the torque does not fluctuate significantly. Static torque sensors are known for their robustness and ability to provide accurate measurements over long periods. They are typically used in applications where the primary concern is the overall torque applied to a system rather than the variations in torque. Both Dynamic and Static Type torque sensors have their unique advantages and are chosen based on the specific requirements of the application. In the automotive industry, Dynamic Type torque sensors are used to monitor the performance of engines and transmissions, providing data that helps in optimizing fuel efficiency and reducing emissions. In contrast, Static Type torque sensors are used in applications such as testing and calibration, where the focus is on measuring the overall torque applied to a component. In the aerospace industry, Dynamic Type torque sensors are used to monitor the performance of aircraft engines and other rotating components, ensuring that they operate within safe limits. Static Type torque sensors, on the other hand, are used in applications such as structural testing, where the focus is on measuring the overall torque applied to a structure. In the marine industry, Dynamic Type torque sensors are used to monitor the performance of ship engines and propulsion systems, providing data that helps in optimizing fuel efficiency and reducing emissions. Static Type torque sensors are used in applications such as testing and calibration, where the focus is on measuring the overall torque applied to a component. In industrial machinery, Dynamic Type torque sensors are used to monitor the performance of rotating components, providing data that helps in optimizing efficiency and reducing downtime. Static Type torque sensors are used in applications such as testing and calibration, where the focus is on measuring the overall torque applied to a component. Overall, the choice between Dynamic and Static Type torque sensors depends on the specific requirements of the application, with each type offering unique advantages in terms of accuracy, reliability, and ease of integration.

Automotive, Aerospace, Marine, Industrial Machinery, Others in the Global Rotation Torque Sensors Market:

The Global Rotation Torque Sensors Market finds extensive usage across various sectors, including automotive, aerospace, marine, industrial machinery, and others. In the automotive industry, torque sensors are crucial for monitoring the performance of engines and transmissions. They provide real-time data that helps in optimizing fuel efficiency, reducing emissions, and ensuring the smooth operation of vehicles. Torque sensors are also used in electric and hybrid vehicles to monitor the performance of electric motors and ensure efficient power distribution. In the aerospace industry, torque sensors play a vital role in monitoring the performance of aircraft engines and other rotating components. They provide data that helps in ensuring the safety and efficiency of aircraft operations, reducing the risk of mechanical failures, and optimizing maintenance schedules. Torque sensors are also used in testing and calibration applications, where they help in ensuring the accuracy and reliability of aircraft components. In the marine industry, torque sensors are used to monitor the performance of ship engines and propulsion systems. They provide data that helps in optimizing fuel efficiency, reducing emissions, and ensuring the smooth operation of ships. Torque sensors are also used in testing and calibration applications, where they help in ensuring the accuracy and reliability of marine components. In industrial machinery, torque sensors are used to monitor the performance of rotating components, providing data that helps in optimizing efficiency and reducing downtime. They are used in applications such as testing and calibration, where they help in ensuring the accuracy and reliability of machinery components. Torque sensors are also used in robotics and automation, where they help in ensuring the precise control of robotic arms and other automated systems. Overall, the Global Rotation Torque Sensors Market plays a crucial role in ensuring the efficiency, safety, and reliability of operations across various sectors. As industries continue to evolve and adopt more advanced technologies, the demand for reliable and high-performance torque sensors is expected to grow, driving innovation and growth in this market.

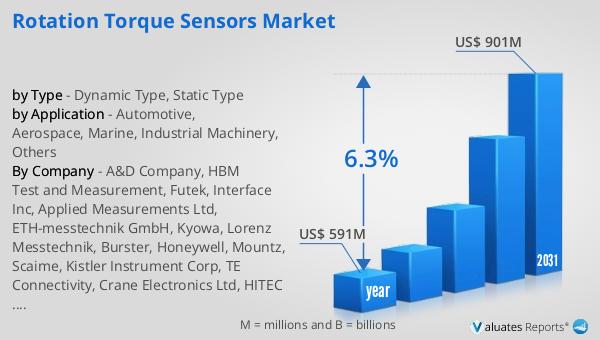

Global Rotation Torque Sensors Market Outlook:

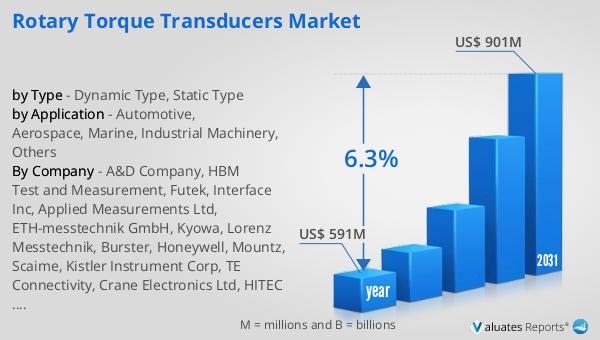

The global market for Rotation Torque Sensors was valued at $591 million in 2024, and it is anticipated to expand to a revised size of $901 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.3% during the forecast period. This growth trajectory underscores the increasing demand for torque sensors across various industries, driven by the need for precise torque measurement and control in mechanical systems. As industries continue to embrace automation and advanced technologies, the role of torque sensors becomes even more critical in ensuring the efficiency and safety of operations. The market's expansion is also fueled by continuous innovation in sensor technology, with manufacturers focusing on developing sensors that offer higher accuracy, durability, and ease of integration into existing systems. This growth is not just limited to traditional industries like automotive and aerospace but also extends to emerging sectors such as robotics and renewable energy, where torque sensors play a vital role in optimizing performance and ensuring reliability. As a result, the Global Rotation Torque Sensors Market is poised for significant growth, driven by technological advancements and the expanding scope of applications across various sectors.

| Report Metric | Details |

| Report Name | Rotation Torque Sensors Market |

| Accounted market size in year | US$ 591 million |

| Forecasted market size in 2031 | US$ 901 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | A&D Company, HBM Test and Measurement, Futek, Interface Inc, Applied Measurements Ltd, ETH-messtechnik GmbH, Kyowa, Lorenz Messtechnik, Burster, Honeywell, Mountz, Scaime, Kistler Instrument Corp, TE Connectivity, Crane Electronics Ltd, HITEC Sensor Developments, Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |