What is Global Aircraft Wire & Cable Market?

The Global Aircraft Wire & Cable Market is a crucial segment within the aerospace industry, focusing on the production and distribution of wires and cables specifically designed for aircraft applications. These components are essential for the safe and efficient operation of both civil and military aircraft, as they are responsible for transmitting electrical power and signals throughout the aircraft. The market encompasses a wide range of products, including power cables, data cables, and specialty cables, each tailored to meet the stringent requirements of the aviation sector. Factors such as the increasing demand for new aircraft, advancements in aviation technology, and the need for lightweight and durable materials drive the growth of this market. Additionally, the market is influenced by regulatory standards and safety protocols that ensure the reliability and performance of these critical components. As the aviation industry continues to evolve, the Global Aircraft Wire & Cable Market plays a vital role in supporting the development of more efficient and technologically advanced aircraft.

PVC insulated wires, PTFE insulated wires, Other in the Global Aircraft Wire & Cable Market:

PVC insulated wires, PTFE insulated wires, and other types of wires are integral components of the Global Aircraft Wire & Cable Market, each offering unique properties that cater to specific needs within the aviation industry. PVC (Polyvinyl Chloride) insulated wires are widely used due to their excellent insulation properties, flexibility, and cost-effectiveness. These wires are suitable for various applications within aircraft, including power distribution and signal transmission. PVC insulation provides good resistance to moisture, chemicals, and abrasion, making it a reliable choice for many aviation applications. However, PVC wires are not ideal for high-temperature environments, which is where PTFE (Polytetrafluoroethylene) insulated wires come into play. PTFE insulated wires are known for their exceptional thermal resistance, making them suitable for use in high-temperature areas of an aircraft. They also offer excellent chemical resistance and electrical properties, ensuring reliable performance under demanding conditions. PTFE wires are often used in critical systems where safety and reliability are paramount. In addition to PVC and PTFE, the market also includes other types of insulated wires, such as those made from silicone, polyimide, and cross-linked polyethylene. Each of these materials offers distinct advantages, such as enhanced flexibility, thermal stability, or resistance to specific environmental factors. The choice of insulation material depends on the specific requirements of the application, including factors like temperature range, mechanical stress, and exposure to chemicals or radiation. As the aviation industry continues to advance, the demand for specialized wires and cables that can withstand the rigors of modern aircraft design and operation is expected to grow. Manufacturers in the Global Aircraft Wire & Cable Market are continually innovating to develop new materials and technologies that meet the evolving needs of the industry. This includes the development of lightweight materials that contribute to fuel efficiency and the reduction of greenhouse gas emissions. Additionally, the integration of advanced data transmission technologies within aircraft systems has led to an increased demand for high-performance data cables that can support the growing complexity of onboard electronics. Overall, the diverse range of insulated wires available in the Global Aircraft Wire & Cable Market reflects the dynamic nature of the aviation industry and its ongoing pursuit of safety, efficiency, and technological advancement.

Civil Aircraft, Military Aircraft in the Global Aircraft Wire & Cable Market:

The Global Aircraft Wire & Cable Market plays a significant role in both civil and military aviation, providing essential components that ensure the safe and efficient operation of aircraft. In the realm of civil aviation, these wires and cables are used extensively in commercial airliners, private jets, and cargo planes. They are responsible for transmitting electrical power and signals throughout the aircraft, supporting critical systems such as navigation, communication, and in-flight entertainment. The demand for reliable and high-performance wires and cables in civil aviation is driven by the increasing number of air travelers and the need for more efficient and technologically advanced aircraft. As airlines strive to enhance passenger experience and operational efficiency, the integration of advanced electronic systems and lightweight materials becomes paramount. This, in turn, fuels the demand for specialized wires and cables that can support these advancements. In military aviation, the Global Aircraft Wire & Cable Market is equally important, as it provides components that are essential for the operation of fighter jets, transport aircraft, and unmanned aerial vehicles (UAVs). Military aircraft require wires and cables that can withstand extreme conditions, including high temperatures, mechanical stress, and exposure to harsh environments. The reliability and performance of these components are critical to the success of military operations, where failure is not an option. The demand for advanced wires and cables in military aviation is driven by the need for enhanced capabilities, such as improved communication systems, advanced radar and surveillance technologies, and increased operational range. As military forces around the world continue to modernize their fleets, the demand for high-performance wires and cables that can support these advancements is expected to grow. Additionally, the increasing use of UAVs in military operations has led to a greater demand for lightweight and durable wires and cables that can support the unique requirements of these aircraft. Overall, the Global Aircraft Wire & Cable Market is a vital component of both civil and military aviation, providing the necessary infrastructure to support the safe and efficient operation of aircraft. As the aviation industry continues to evolve, the demand for specialized wires and cables that can meet the unique challenges of modern aircraft design and operation is expected to increase, driving innovation and growth within the market.

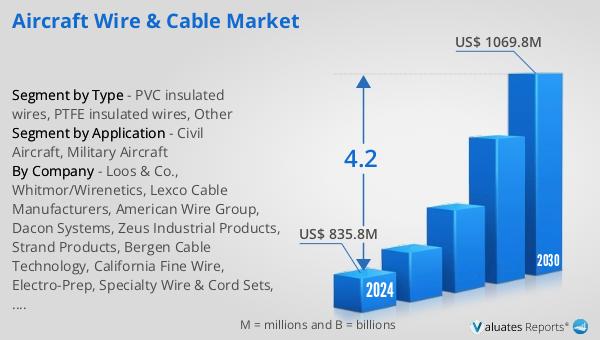

Global Aircraft Wire & Cable Market Outlook:

The global market for aircraft wire and cable was valued at approximately $867 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $1,152 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for new aircraft, advancements in aviation technology, and the need for lightweight and durable materials. As the aviation industry continues to evolve, the demand for specialized wires and cables that can support the development of more efficient and technologically advanced aircraft is expected to grow. This growth is further supported by the increasing number of air travelers and the need for more efficient and technologically advanced aircraft in both civil and military aviation. Additionally, the integration of advanced electronic systems and lightweight materials in aircraft design is driving the demand for high-performance wires and cables that can support these advancements. As a result, the Global Aircraft Wire & Cable Market is poised for significant growth in the coming years, providing opportunities for manufacturers and suppliers to innovate and meet the evolving needs of the aviation industry.

| Report Metric | Details |

| Report Name | Aircraft Wire & Cable Market |

| Accounted market size in year | US$ 867 million |

| Forecasted market size in 2031 | US$ 1152 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Loos & Co., Whitmor/Wirenetics, Lexco Cable Manufacturers, American Wire Group, Dacon Systems, Zeus Industrial Products, Strand Products, Bergen Cable Technology, California Fine Wire, Electro-Prep, Specialty Wire & Cord Sets, Interconnect Cable Technologies Corp., Multi/Cable Corp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |