What is Global Expandable Shelter Market?

The Global Expandable Shelter Market is a dynamic and innovative sector that focuses on the development and distribution of portable, flexible, and easily deployable shelters. These shelters are designed to be quickly assembled and disassembled, making them ideal for a variety of applications, including military operations, disaster relief, and temporary housing. The market is driven by the increasing need for rapid deployment solutions in emergency situations and the growing demand for versatile and cost-effective shelter options. Expandable shelters are constructed using advanced materials and technologies that ensure durability, weather resistance, and ease of transportation. They come in various sizes and configurations, catering to different needs and environments. The market is characterized by continuous advancements in design and functionality, with manufacturers striving to enhance the efficiency and adaptability of these shelters. As global challenges such as natural disasters and humanitarian crises continue to rise, the demand for expandable shelters is expected to grow, offering a promising outlook for the industry. The market's growth is also supported by government investments and collaborations with private companies to develop innovative shelter solutions that can be deployed in diverse settings.

Small Expandable Shelter, Large Expandable Shelter in the Global Expandable Shelter Market:

In the Global Expandable Shelter Market, small and large expandable shelters serve distinct purposes, each tailored to specific needs and scenarios. Small expandable shelters are typically compact and lightweight, designed for quick deployment and easy transportation. They are often used in situations where space is limited or where rapid setup is crucial, such as in emergency response operations or temporary field camps. These shelters can be expanded to provide essential living or working space, offering basic amenities and protection from the elements. Their portability makes them ideal for use in remote or hard-to-reach areas, where traditional construction methods may be impractical. On the other hand, large expandable shelters are designed to accommodate more people or equipment, providing a more spacious and versatile environment. These shelters are often used in military operations, where they can serve as command centers, barracks, or storage facilities. They are also utilized in disaster relief efforts, providing temporary housing or medical facilities for displaced populations. Large expandable shelters are constructed with robust materials and advanced engineering techniques to ensure stability and durability, even in harsh conditions. They can be equipped with various features, such as climate control systems, lighting, and communication equipment, to enhance their functionality and comfort. Both small and large expandable shelters play a crucial role in the Global Expandable Shelter Market, addressing the diverse needs of different sectors and applications. Manufacturers continue to innovate and improve these shelters, focusing on enhancing their efficiency, sustainability, and adaptability to meet the evolving demands of the market. As the world faces increasing challenges such as climate change, conflict, and population displacement, the importance of expandable shelters is likely to grow, driving further advancements and opportunities in this dynamic market.

Command Post, Medical Facility Base, Aircraft and Vehicle Maintenance in the Global Expandable Shelter Market:

The Global Expandable Shelter Market finds significant applications in various areas, including command posts, medical facility bases, and aircraft and vehicle maintenance. In military operations, expandable shelters serve as command posts, providing a secure and efficient environment for planning and coordination. These shelters are equipped with advanced communication systems, enabling seamless connectivity and information sharing among personnel. They offer a flexible and adaptable space that can be customized to meet the specific needs of different missions, ensuring operational efficiency and effectiveness. In the medical field, expandable shelters are used as temporary medical facility bases, providing essential healthcare services in remote or disaster-stricken areas. These shelters can be quickly deployed and set up, offering a sterile and controlled environment for medical personnel to perform surgeries, administer treatments, and care for patients. They are equipped with necessary medical equipment and supplies, ensuring that healthcare services can be delivered promptly and efficiently. Expandable shelters are also utilized in aircraft and vehicle maintenance, providing a protected and controlled environment for technicians to perform repairs and maintenance tasks. These shelters offer a versatile and adaptable space that can be customized to accommodate different types of aircraft and vehicles, ensuring that maintenance operations can be carried out efficiently and effectively. The use of expandable shelters in these areas highlights their versatility and adaptability, making them an essential component of the Global Expandable Shelter Market. As the demand for rapid deployment solutions continues to grow, the market is expected to expand, offering new opportunities and innovations in the development and application of expandable shelters.

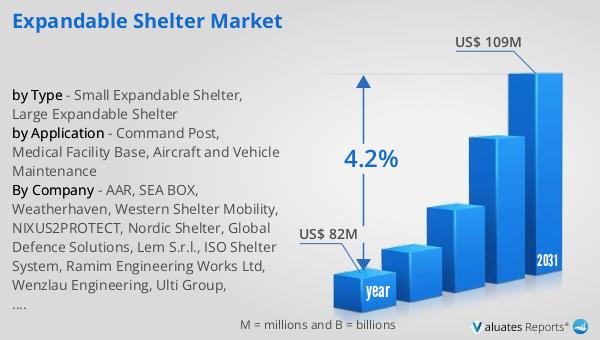

Global Expandable Shelter Market Outlook:

The global market for expandable shelters was valued at approximately $82 million in 2024, and it is anticipated to grow to a revised size of around $109 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. The market's expansion is driven by the increasing demand for versatile and rapidly deployable shelter solutions across various sectors, including military, disaster relief, and temporary housing. The need for efficient and cost-effective shelter options is becoming more critical as global challenges such as natural disasters, humanitarian crises, and military operations continue to rise. Expandable shelters offer a practical and adaptable solution, providing essential protection and amenities in diverse environments. The market's growth is also supported by advancements in materials and technologies, which enhance the durability, functionality, and ease of transportation of these shelters. As governments and organizations invest in innovative shelter solutions, the market is expected to witness further growth and development. The projected increase in market size reflects the growing recognition of the importance of expandable shelters in addressing the evolving needs of various sectors and applications.

| Report Metric | Details |

| Report Name | Expandable Shelter Market |

| Accounted market size in year | US$ 82 million |

| Forecasted market size in 2031 | US$ 109 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AAR, SEA BOX, Weatherhaven, Western Shelter Mobility, NIXUS2PROTECT, Nordic Shelter, Global Defence Solutions, Lem S.r.l., ISO Shelter System, Ramim Engineering Works Ltd, Wenzlau Engineering, Ulti Group, RITVEYRAAJ, General Dynamics, HDT Global |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |