What is Global Green Polypropylene Market?

The Global Green Polypropylene Market is an emerging sector focused on producing polypropylene, a type of plastic, using environmentally friendly methods. Traditional polypropylene is derived from petroleum-based sources, which contribute to carbon emissions and environmental degradation. In contrast, green polypropylene is produced using renewable resources, such as plant-based materials, which significantly reduce its carbon footprint. This shift towards sustainable production is driven by increasing environmental awareness and regulatory pressures to reduce plastic waste and carbon emissions. The market for green polypropylene is expanding as industries seek sustainable alternatives to traditional plastics. This growth is supported by advancements in technology that make the production of green polypropylene more efficient and cost-effective. As a result, green polypropylene is becoming a viable option for various applications, including packaging, automotive parts, and consumer goods, where sustainability is increasingly prioritized. The transition to green polypropylene not only helps in reducing environmental impact but also aligns with the global movement towards a circular economy, where materials are reused and recycled to minimize waste. This market is poised for significant growth as more industries adopt sustainable practices and consumers demand eco-friendly products.

Isotactic Polypropylene, Atactic Polypropylene, Syndiotactic Polypropylene in the Global Green Polypropylene Market:

Isotactic polypropylene, atactic polypropylene, and syndiotactic polypropylene are three types of polypropylene that differ in their molecular structure, which affects their properties and applications. In the context of the Global Green Polypropylene Market, these variations are produced using sustainable methods, aligning with the market's focus on reducing environmental impact. Isotactic polypropylene is the most common form, characterized by a regular arrangement of methyl groups on the same side of the polymer chain. This structure gives it high crystallinity, resulting in a material that is strong, rigid, and resistant to chemicals and heat. These properties make isotactic polypropylene suitable for applications requiring durability and stability, such as automotive parts, packaging, and textiles. In the green polypropylene market, isotactic polypropylene is produced using bio-based feedstocks, reducing reliance on fossil fuels and lowering carbon emissions. Atactic polypropylene, on the other hand, has a random arrangement of methyl groups, leading to a material that is amorphous and lacks the crystalline structure of its isotactic counterpart. This gives atactic polypropylene a softer, more rubber-like texture, making it useful as a sealant or adhesive. In the green polypropylene market, atactic polypropylene is produced using sustainable processes that minimize environmental impact while maintaining its desirable properties. Syndiotactic polypropylene features an alternating arrangement of methyl groups, resulting in a material with a unique combination of properties. It offers a balance between the rigidity of isotactic polypropylene and the flexibility of atactic polypropylene, making it suitable for applications that require both strength and flexibility. In the green polypropylene market, syndiotactic polypropylene is produced using innovative techniques that prioritize sustainability, such as using renewable resources and energy-efficient processes. The production of these types of polypropylene in the green market involves advanced technologies that enhance their properties while reducing environmental impact. This includes the use of catalysts that improve polymerization efficiency and the development of bio-based feedstocks that replace traditional petroleum-based sources. As the demand for sustainable materials grows, the green polypropylene market is expected to expand, offering a range of options for industries seeking eco-friendly alternatives to conventional plastics. The versatility of isotactic, atactic, and syndiotactic polypropylene, combined with their sustainable production methods, positions them as key materials in the transition towards a more sustainable future.

Construction, Automotive, Packaging, Industrial, Others in the Global Green Polypropylene Market:

The Global Green Polypropylene Market finds applications across various sectors, including construction, automotive, packaging, industrial, and others, driven by the need for sustainable materials. In the construction industry, green polypropylene is used for producing pipes, insulation materials, and fittings. Its durability, resistance to chemicals, and lightweight nature make it an ideal choice for construction applications. The use of green polypropylene in construction not only reduces the carbon footprint of building projects but also contributes to the development of sustainable infrastructure. In the automotive sector, green polypropylene is used for manufacturing interior and exterior components, such as dashboards, bumpers, and trim. Its lightweight nature helps in reducing the overall weight of vehicles, leading to improved fuel efficiency and reduced emissions. The use of green polypropylene in automotive applications aligns with the industry's shift towards sustainable practices and the development of eco-friendly vehicles. In the packaging industry, green polypropylene is used for producing containers, films, and wraps. Its strength, flexibility, and resistance to moisture make it an ideal material for packaging applications. The use of green polypropylene in packaging helps in reducing plastic waste and supports the development of sustainable packaging solutions. In the industrial sector, green polypropylene is used for producing components and parts for machinery and equipment. Its resistance to chemicals and heat makes it suitable for industrial applications that require durable and reliable materials. The use of green polypropylene in the industrial sector supports the development of sustainable manufacturing processes and reduces the environmental impact of industrial activities. In addition to these sectors, green polypropylene is also used in other applications, such as consumer goods, textiles, and medical devices. Its versatility and sustainable production methods make it a preferred choice for industries seeking eco-friendly alternatives to traditional plastics. The use of green polypropylene across various sectors not only helps in reducing environmental impact but also supports the global movement towards sustainability and the development of a circular economy. As industries continue to adopt sustainable practices, the demand for green polypropylene is expected to grow, offering a range of opportunities for innovation and development in the market.

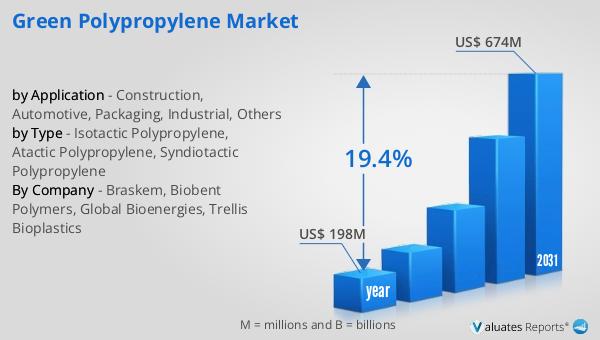

Global Green Polypropylene Market Outlook:

The global market for green polypropylene is experiencing significant growth, driven by increasing demand for sustainable materials and the need to reduce environmental impact. In 2024, the market was valued at approximately $198 million, reflecting the growing interest in eco-friendly alternatives to traditional plastics. This market is projected to expand rapidly, reaching an estimated size of $674 million by 2031. This growth represents a compound annual growth rate (CAGR) of 19.4% during the forecast period, highlighting the strong momentum behind the adoption of green polypropylene. The expansion of the green polypropylene market is supported by advancements in technology that make the production of sustainable materials more efficient and cost-effective. As industries across various sectors, including construction, automotive, packaging, and industrial, increasingly prioritize sustainability, the demand for green polypropylene is expected to rise. This growth is also driven by regulatory pressures to reduce plastic waste and carbon emissions, as well as increasing consumer awareness and demand for eco-friendly products. The transition to green polypropylene not only helps in reducing environmental impact but also aligns with the global movement towards a circular economy, where materials are reused and recycled to minimize waste. As the market continues to grow, it offers a range of opportunities for innovation and development, positioning green polypropylene as a key material in the transition towards a more sustainable future.

| Report Metric | Details |

| Report Name | Green Polypropylene Market |

| Accounted market size in year | US$ 198 million |

| Forecasted market size in 2031 | US$ 674 million |

| CAGR | 19.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Braskem, Biobent Polymers, Global Bioenergies, Trellis Bioplastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |