What is Global Composite Plate Market?

The Global Composite Plate Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. Composite plates are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, these materials produce a composite with characteristics different from the individual components. The global market for composite plates is driven by their lightweight nature, high strength, and durability, making them ideal for applications in industries such as aerospace, automotive, construction, and marine. These plates are used to enhance performance, reduce weight, and improve fuel efficiency, which is increasingly important in today's environmentally conscious world. The market is also influenced by technological advancements and innovations in composite materials, which continue to expand their applications and improve their performance. As industries strive for more sustainable and efficient solutions, the demand for composite plates is expected to grow, offering significant opportunities for manufacturers and suppliers in this market. The global composite plate market is characterized by a diverse range of products, including carbon fiber composites, glass fiber composites, and aramid fiber composites, each offering unique benefits and applications.

Explosion Bonded, Roll Bonded in the Global Composite Plate Market:

Explosion bonded and roll bonded composite plates are two significant types of composite materials used in various industrial applications. Explosion bonding is a solid-state welding process that uses controlled explosive energy to bond two or more dissimilar metals. This process is particularly useful for creating composite plates with high-strength bonds and excellent corrosion resistance. Explosion bonded composite plates are widely used in industries where durability and resistance to harsh environments are critical, such as in the oil and gas, chemical, and marine industries. The process involves placing a layer of explosive material between the metal plates, which, when detonated, creates a high-pressure wave that bonds the metals together. This method allows for the creation of large, complex shapes and is ideal for bonding metals that are difficult to weld using traditional methods. On the other hand, roll bonding is a process that involves passing two or more metal sheets through a pair of rollers under high pressure. This mechanical process creates a metallurgical bond between the layers, resulting in a composite plate with excellent mechanical properties. Roll bonded composite plates are commonly used in applications where uniform thickness and high strength are required, such as in the automotive and aerospace industries. The roll bonding process is highly efficient and cost-effective, making it suitable for large-scale production. Both explosion bonded and roll bonded composite plates offer unique advantages and are chosen based on the specific requirements of the application. The choice between these two methods depends on factors such as the types of metals being bonded, the desired properties of the final product, and the intended application. As the demand for lightweight, high-strength materials continues to grow, both explosion bonded and roll bonded composite plates are expected to see increased use across various industries. The global composite plate market is poised for growth, driven by the need for advanced materials that can meet the demands of modern industrial applications. Manufacturers are continually exploring new materials and bonding techniques to enhance the performance and expand the applications of composite plates. This ongoing innovation is crucial for meeting the evolving needs of industries and maintaining competitiveness in the global market.

Oil & Gas, Chemical Industry, Water Treatment, Others in the Global Composite Plate Market:

The Global Composite Plate Market finds extensive usage across various sectors, including oil and gas, the chemical industry, water treatment, and others. In the oil and gas industry, composite plates are used for their excellent corrosion resistance and high strength-to-weight ratio. These properties make them ideal for use in offshore platforms, pipelines, and storage tanks, where harsh environmental conditions and the need for lightweight materials are critical considerations. Composite plates help extend the lifespan of equipment and reduce maintenance costs, making them a valuable asset in this industry. In the chemical industry, composite plates are used in the construction of chemical processing equipment, such as reactors, heat exchangers, and storage vessels. Their resistance to chemical corrosion and ability to withstand high temperatures make them suitable for handling aggressive chemicals and high-pressure environments. This enhances the safety and efficiency of chemical processing operations, contributing to improved productivity and reduced downtime. In water treatment facilities, composite plates are used in the construction of tanks, pipes, and filtration systems. Their resistance to corrosion and biofouling makes them ideal for use in environments where exposure to water and chemicals is constant. Composite plates help ensure the longevity and reliability of water treatment infrastructure, which is essential for providing clean and safe water to communities. Beyond these industries, composite plates are also used in a variety of other applications, including construction, automotive, and aerospace. In construction, they are used for building facades, bridges, and other structures where lightweight and durable materials are required. In the automotive industry, composite plates are used to reduce vehicle weight and improve fuel efficiency, while in aerospace, they are used in the construction of aircraft components to enhance performance and reduce emissions. The versatility and performance benefits of composite plates make them a valuable material in a wide range of applications, driving their demand in the global market. As industries continue to seek innovative solutions to improve efficiency and sustainability, the use of composite plates is expected to grow, offering significant opportunities for manufacturers and suppliers in this market.

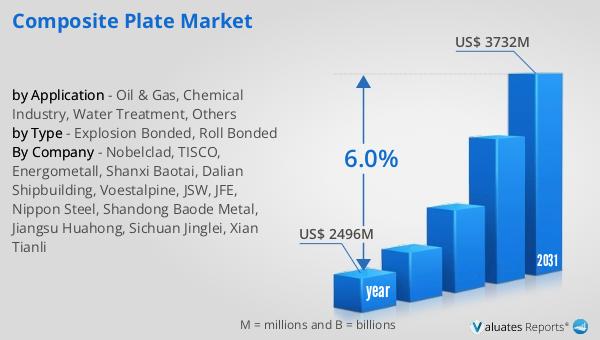

Global Composite Plate Market Outlook:

The global market for composite plates was valued at approximately $2,496 million in 2024. It is anticipated to expand significantly, reaching an estimated size of $3,732 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.0% over the forecast period. This upward trend is indicative of the increasing demand for composite plates across various industries, driven by their unique properties and advantages. The market's expansion is fueled by the growing need for lightweight, high-strength materials that can enhance performance and efficiency in applications ranging from aerospace to automotive and construction. As industries continue to prioritize sustainability and cost-effectiveness, composite plates offer a viable solution due to their durability, corrosion resistance, and ability to withstand harsh environments. The projected growth of the composite plate market reflects the ongoing innovation and development within the industry, as manufacturers strive to meet the evolving needs of their customers. This growth also highlights the importance of composite plates in addressing the challenges faced by modern industries, such as reducing emissions, improving fuel efficiency, and enhancing the longevity of equipment and infrastructure. As the market continues to evolve, it presents significant opportunities for businesses to capitalize on the increasing demand for advanced materials and technologies.

| Report Metric | Details |

| Report Name | Composite Plate Market |

| Accounted market size in year | US$ 2496 million |

| Forecasted market size in 2031 | US$ 3732 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nobelclad, TISCO, Energometall, Shanxi Baotai, Dalian Shipbuilding, Voestalpine, JSW, JFE, Nippon Steel, Shandong Baode Metal, Jiangsu Huahong, Sichuan Jinglei, Xian Tianli |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |