What is Global Copper Conductive Paste Market?

The Global Copper Conductive Paste Market is a significant segment within the broader conductive materials industry, primarily driven by its extensive application in electronics and electrical components. Copper conductive paste is a type of material that facilitates the conduction of electricity and is used in various electronic devices and components. It is composed of copper particles suspended in a medium that allows it to be applied as a paste. This paste is then used to create conductive pathways on electronic circuits, which are essential for the functioning of devices like smartphones, computers, and other electronic gadgets. The market for copper conductive paste is expanding due to the increasing demand for miniaturized and efficient electronic devices. As technology advances, the need for materials that can provide reliable conductivity while being cost-effective and environmentally friendly is becoming more pronounced. Copper, being a cheaper alternative to silver, is gaining popularity in this regard. The market is also influenced by the growing trend of renewable energy sources, where copper conductive paste is used in solar panels and other energy-efficient technologies. Overall, the Global Copper Conductive Paste Market is poised for growth as it continues to adapt to the evolving needs of the electronics industry.

Low Temperature Sintered, Medium Temperature Sintered, High Temperature Sintered in the Global Copper Conductive Paste Market:

In the Global Copper Conductive Paste Market, the sintering process plays a crucial role in determining the properties and applications of the paste. Sintering is a method used to compact and form solid materials by applying heat or pressure without melting them to the point of liquefaction. There are three main types of sintering processes used in the production of copper conductive paste: low temperature sintered, medium temperature sintered, and high temperature sintered. Each of these processes has its own set of characteristics and applications. Low temperature sintered copper conductive paste is designed to be processed at temperatures typically below 300°C. This type of paste is particularly useful in applications where heat-sensitive substrates are involved, such as certain types of plastics or flexible electronics. The low processing temperature helps in preventing damage to these substrates while still providing adequate conductivity. This makes low temperature sintered paste ideal for use in flexible printed circuits and other applications where thermal management is a concern. Medium temperature sintered copper conductive paste is processed at temperatures ranging from 300°C to 600°C. This type of paste strikes a balance between conductivity and thermal stability, making it suitable for a wide range of applications. It is often used in the production of multilayer ceramic capacitors (MLCCs) and other components where moderate heat resistance is required. The medium temperature sintering process allows for the formation of strong conductive pathways while maintaining the integrity of the substrate. High temperature sintered copper conductive paste is processed at temperatures above 600°C. This type of paste is used in applications where high thermal stability and excellent conductivity are required. It is commonly used in the production of power electronics, automotive components, and other high-performance applications. The high temperature sintering process results in a dense and robust conductive layer that can withstand harsh operating conditions. Each of these sintering processes offers unique advantages and is chosen based on the specific requirements of the application. The choice of sintering temperature affects not only the conductivity and thermal stability of the paste but also its adhesion to the substrate and overall performance. As the demand for more efficient and reliable electronic components continues to grow, the development and optimization of sintering processes for copper conductive paste will remain a key focus in the industry.

PCB, MLCC, Others in the Global Copper Conductive Paste Market:

The Global Copper Conductive Paste Market finds its usage in various applications, with printed circuit boards (PCBs), multilayer ceramic capacitors (MLCCs), and other areas being some of the most prominent. In the realm of PCBs, copper conductive paste is used to create the intricate network of conductive pathways that connect different components on the board. This is crucial for the functioning of electronic devices, as it allows for the transmission of electrical signals between components. The use of copper conductive paste in PCBs offers several advantages, including cost-effectiveness, good electrical conductivity, and compatibility with various substrates. As electronic devices become more compact and complex, the demand for efficient and reliable conductive materials like copper paste is increasing. In the case of MLCCs, copper conductive paste is used to form the internal electrodes of the capacitors. MLCCs are widely used in electronic devices for their ability to store and release electrical energy. The use of copper paste in MLCCs helps in achieving high capacitance values while maintaining a small form factor. This is particularly important in modern electronic devices, where space is at a premium. The use of copper conductive paste in MLCCs also contributes to the overall cost-effectiveness of the components, as copper is a more affordable alternative to other conductive materials like silver. Apart from PCBs and MLCCs, copper conductive paste is also used in a variety of other applications. These include solar cells, where the paste is used to form the conductive grid on the surface of the cell, and automotive electronics, where it is used in the production of sensors and other components. The versatility of copper conductive paste makes it a valuable material in the electronics industry, as it can be tailored to meet the specific requirements of different applications. The growing demand for renewable energy sources and the increasing complexity of electronic devices are driving the need for advanced conductive materials like copper paste. As the Global Copper Conductive Paste Market continues to evolve, it is expected to play a crucial role in the development of new technologies and the advancement of existing ones.

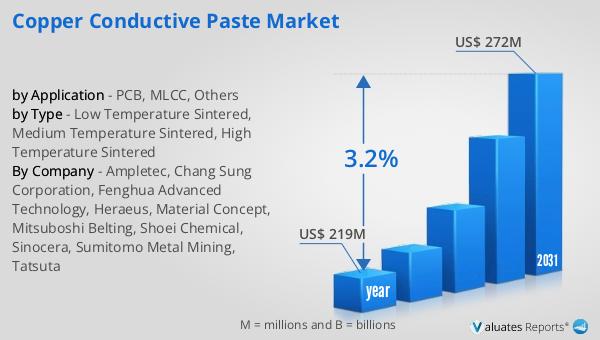

Global Copper Conductive Paste Market Outlook:

The outlook for the Global Copper Conductive Paste Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 219 million. By 2031, it is anticipated to expand to a revised size of around US$ 272 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.2% during the forecast period. The increase in market size can be attributed to several factors, including the rising demand for electronic devices, the growing trend of miniaturization in electronics, and the increasing adoption of renewable energy technologies. Copper conductive paste is gaining popularity due to its cost-effectiveness and excellent electrical conductivity, making it a preferred choice for manufacturers looking to optimize performance while reducing costs. Additionally, the shift towards more environmentally friendly materials in the electronics industry is further boosting the demand for copper conductive paste. As the market continues to grow, manufacturers are likely to focus on developing new formulations and improving existing ones to meet the evolving needs of the industry. The steady growth of the Global Copper Conductive Paste Market reflects the ongoing advancements in technology and the increasing importance of efficient and reliable conductive materials in modern electronics.

| Report Metric | Details |

| Report Name | Copper Conductive Paste Market |

| Accounted market size in year | US$ 219 million |

| Forecasted market size in 2031 | US$ 272 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ampletec, Chang Sung Corporation, Fenghua Advanced Technology, Heraeus, Material Concept, Mitsuboshi Belting, Shoei Chemical, Sinocera, Sumitomo Metal Mining, Tatsuta |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |